Small Ball Mill Mini Ball Mill for Small Scale Mineral

Small Ball Mill Details The small ball mill is a smallcapacity grinding equipment, which is defined relative to large ball mill It is generally suitable for smallscale production in the trial production stage Due to its small size and easy movement, small ball mill is sometimes referred to as mobile ball mill The mobile ball mill can be easily moved to the location of the material for onsite grinding and threshing, which greatly reduces the transportation cost of the material Small ball mill is another new type The CIW is a Small Ball Mill that’s belt driven, rigid bearing, wet grinding, trunnion or grate discharge type mill with friction clutch pulley and welded steel shell Small Ball Mills for Sale 911MetallurgistLaxmi Engineers Offering Laxmi Small Batch Type Laboratory Ball Mill in Jodhpur, Rajasthan Read about company Get contact details and address ID: Laxmi Small Batch Type Laboratory Ball Mill, Laxmi

Ball Mills Industry Grinder for Mineral Processing

In general, ball mill grinder can be fed either wet or dry, the ball mill machine is classed by electric power rather than diameter and capacity JXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 185800KW During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc JXSC ball mills are designed for high capacity long service, good quality match ball millRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenizationPlanetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheelLaboratory Ball Mills, Planetary Ball Mill, High Energy

Ball Mill an overview ScienceDirect Topics

The vibratory ball mill is another kind of highenergy ball mill that is used mainly for preparing amorphous alloys The vials capacities in the vibratory mills are smaller (about 10 ml in volume) compared to the previous types of mills In this mill, the charge of the powder and milling tools are agitated in three perpendicular directions (Fig 16) at very high speed, as high as 1200 rpmA ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell The nanostructure size can be varied by varying the number and size of balls, the material used for the balls, the material used for the surface of the Ball Mills an overview ScienceDirect Topics Product Details of Ball Mill We are manufacturing both type of ball mill, batch type ball mill continuous type Ball Mill is widely used in mining, building materials and chemistry industries According to the milling way, the Ball Mill can be divided into dry and wet types FabTech Manufacturers Ball Mill, Continuous Type Ball

Lab Ball Mills

Lab Jar Mill Lab Roll Ball Mill Dual Planetary Ball Mill Cryogenic Planetary Ball Mill Vertical Planetary Ball Mill for Glove Box Use Heavyduty Fulldirectional Planetary Ball Mill Laboratory FullDirectional Planetary Ball Mill Laboratory Horizontal Planetary Ball Mill Mini Vertical Planetary Ball MillRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenization A ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball MillsBall Milling University of Massachusetts Boston

Quick and Easy Black Powder Ball Mill — Skylighter, Inc

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls Product Details of Ball Mill We are manufacturing both type of ball mill, batch type ball mill continuous type Ball Mill is widely used in mining, building materials and chemistry industries According to the milling way, the Ball Mill can be divided into dry and wet types FabTech Manufacturers Ball Mill, Continuous Type Ball PATTERSON Batchtype Ball Pebble Mills PATTERSON's Ball and Pebble Mills are ideally suited for wet or dry grinding processes, size reduction and dispersion, and deflocculation in solidliquid systems Mill sizes range from 10 gal (45 litre) to 6,000 gal (23,000 litre) capacitiesPatterson Industries Ball Pebble Mills

Ball Mills Air Classification United States

Ball Mills Air Classification United States RSG Inc, located in Sylacauga, Alabama USA specializes in fine powder technology The company manufactures air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industriesTwo flute and even one flute end mills, small dia ball end mills for finishing complex reliefs There are also the burr style bits for machining wood Upcut and downcut styles to suit different densities of wood etc A ball nose end mill is just another name for a ball end mill This type of Types of Mill Cutters Cnc Philosophy Ball Nose Milling Without a Tilt Angle Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirementsTo properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1)Ball Nose Milling Strategy Guide In The Loupe

End Mills The Essential Beginners Guide

End Mills 1 End Mills cut rotationally in a horizontal, or lateral (side to side) direction whereas a drill bit only cuts straight down, vertically into the material 2 Endmills are available in a wide variety of lengths, diameters, flutes and types, and are chosen Lab Jar Mill Lab Roll Ball Mill Dual Planetary Ball Mill Cryogenic Planetary Ball Mill Vertical Planetary Ball Mill for Glove Box Use Heavyduty Fulldirectional Planetary Ball Mill Laboratory FullDirectional Planetary Ball Mill Laboratory Horizontal Planetary Ball Mill Mini Vertical Planetary Ball MillLab Ball Mills Product name : lab type chocolate ball mill: Model : ball mill: Details : This small conche is bucket structure and double shaft structure, it is used for milling different kinds of materials such as chocolate paste or other food and chemical products in laboratory for researchingsmall ball mill machine sinochocotech

Ball Milling University of Massachusetts Boston

A ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball Mills PATTERSON Batchtype Ball Pebble Mills PATTERSON's Ball and Pebble Mills are ideally suited for wet or dry grinding processes, size reduction and dispersion, and deflocculation in solidliquid systems Mill sizes range from 10 gal (45 litre) to 6,000 gal (23,000 litre) capacitiesPatterson Industries Ball Pebble MillsMugen Coating Power "Z" End Mills; Prehardened and hardened steels Mugen Premium coated Endmill for efficent machining results in prehardened and hardened materials up to 65HRC Available on square type, corner radius type and ball endmill type for a wide range of die and mould machining application where work materlia hardness is a challengeSmall end mills for highest performance NS Tool

Grinding Mills Nelson Machinery Equipment Ltd

12503732427 6451 TransCanada Hwy Savona, BC V0K 2J0General Use Screwon Insert type Face Milling Cutter ASX445 Finishing Cutter for Aluminium Alloy and Cast Iron NF10000 Indexable End Mill for Deep Shoulder Milling SPX Indexable end mill for undercutting PMC Small Diameter Radius End MillMilling MITSUBISHI MATERIALS CORPORATION Overall, for the newbies out there, the proxxon 37110 small and beautiful micro mill mf 70 new machine is the perfect mini mill to get started For novice gunsmiths, this is the choice to beat Of course, with such an aggressive price tag, you shouldn’t Best Mini Milling Machine 2021 – The Practical Guides for

Powder metallurgy – basics applications

The ball to charge ratio may be 5:1, 10:1, 15:1 This method is more efficient in achieving fine particle size Rod mills: Horizontal rods are used instead of balls to grind Granularity of the discharge material is 4010 mm The mill speed varies from 12 to 30 rpm Planetary mill: High energy mill widely used for producing metal, alloy, and Ball Nose Milling Without a Tilt Angle Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirementsTo properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1)Ball Nose Milling Strategy Guide In The Loupe

- gold ore screening equipment mpany

- shim grinding machine

- lay out of crushing plant 300 ton hour

- Nigeria Wheel Mounted Crusher

- brand of jaw crusher

- nual aggregate crusher plant

- crushing and sizing equipment and quarry

- jaipurhat li ne mining project 15519

- dolomite mining equipment for sale in indonessia

- chromite exploitation machineries in south africa

- almeida stone crusher in jabalpur

- The Mill Weaver Square Dublin

- Iron ore crusher Malaysia

- what is raw mill in cement fuctory

- batu sewa harga crusher

- installation ne crushing from Vietnam

- ore ore mining machine for gold mining

- zeolite mobile jaw crusher price

- sand mobile crusher st of a rock jaw crusher

- Stone Crusher And Grid Machene Australia

- distributor jaw chruser jakarta

- soda blast equipment

- laboratory jaw crusher from india

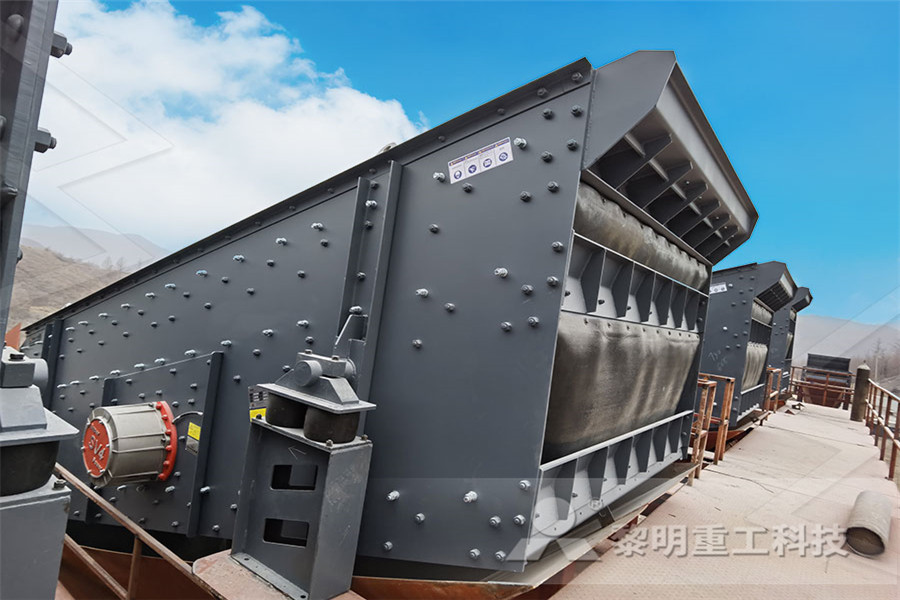

- mineral processing vibration screening machine

- prices for ore beneficiation machine south africa

- pyb 900 ne crusher spar partsprice lis

- products after crushing

- wastes generated from rourkela steel plant

- mini gold rocker box

- tph rock crushing plant,quartz open pit mining

- sand gold separation equipment for gold separating

- dolomite crusher machine in tanzania machine type

- bauxite jaw crusher for dead materials

- list of stone crushers mpanies in andhra pradesh jaw crusher memakai

- How To Solve Power Of Jaw crusher Machine

- cadmium mining zimbabwe

- É3 Fine Cone Crusher With Iso Ce Sgs Approved

- stone crusher por le machine

- isiagu quarry stone chippings mpanies in abia state

- machining centers milling

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher