portland clinker grinding machinery

Portland cement clinker raw Guilin HCM Machinery Cement Clinker powder processing technological process Phrase one Cement clinker crushing Cement clinker blocks will be crushed to 15mm50mm fineness by crusher Phrase two grinding Crushed cement clinker will be sent to the storage hopper by the elevator and then the feeder will send the material Cement Clinker Portland / Cement Grinding Plant / Cement ball mill / cement mill Introduction Cement mill is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramicsCement Clinker Portland / Cement Grinding Plant / portland clinker grinding machinery portland clinker grinding machinery portland clinker grinding machinery dieboldbaueu Clinker Ball Mill For Cement Grinding Plant pimeu Portland Cement Clinker Grinding Plants When the large initial capital investment is a hindrance or the local , Gold Detector Making Machine Clinker Grinding ,portland clinker grinding machinery

PPC Cement Manufacturing Process Portland Pozzolana

Portland pozzolana cement shall be manufactured by mixing and intergrinding Portland cement clinker, pozzolanic materials, and gypsum The manufacturing process is approximately the same as ordinary Portland cement, which can be divided into four processes: raw material crushing, raw material grinding, clinker calcination, and cement grindingChina Ordinary Portland Clinker, China Ordinary Portland Clinker Suppliers and Manufacturers Directory Source a Large Selection of Ordinary Portland Clinker Products at portland clinker,portland cement,cement clinker from China AlibabaChina Ordinary Portland Clinker, China Ordinary Portland Cement Grinding: cement grinding is the final stage in Portland cement manufacturing In this step, clinker will be ground in grinding mill to reach the qualified fineness of cement product During the grinding, we usually add gypsum, fly ash and other raw materials into the cement to realize the different usage of cementPortland Cement Manufacturing Process In Cement Plant

Portland Cement Clinker Lafarge Canada

Additional Hazards When Processed: Cutting, crushing or grinding cement clinker, hardened cement, concrete or other crystalline silicabearing materials will release respirable crystalline silica Use all appropriate measures of dust control or suppression, and Personal Protective Equipment (PPE) described in Section 8 belowClinker Cement Machine Cement Clinker Grinding Machine Complete Clinker Cement Grinding Production Line Machine $83,00000$280,00000/ Set 1 Set (Min Order) CN Henan Zhengzhou Mining Machinery Co, Ltd 13 YRS Contact Supplier Ad Add to FavoritesTopQuality cement clinker making machine at This clinker grinding plant is comprised of material handling equipment, pre crusher, feed hopper, table feeders, ball mill and packing plant Designed to handle the broadest possible range of friable materials, this versatile clinker grinder incorporates a host of design features that improve efficiency and reliability in bottom ash handling Clinker Grinding Plant CLINKER GRINDING PLANT

Clinker Production Clinker Manufacturing Cement

Cement kiln is the main equipment for clinker sintering From structure, it can be divided into rotary cement kiln and shaft kiln, while, from the working principle, it can be divided into the dry method and wet method kiln AGICO offers different types of cement kilns from 105000t/d with steady running, high efficiency and large outputPortland cement manufacturing process can be divided into 6 steps: raw material crushing, prehomogenization, fine grinding, clinker production, cement grinding, cement packing, etc In these processes, we need the assistance of different kinds of cement equipment , such as cement kilns, cement mills, and cement crushersPortland Cement Manufacturing – Ordinary Portland 幻灯片17 4Grinding system Ball mill is the earliest grinding equipment used in cement production industry, and it still plays a leading role Although its efficiency is very low, for example, the power consumption of single particle is only 6% 9%, the maintenance of ball mill is simple and reliable, especially for cement clinker grindingCement Production Line, Cement machinery, Rotary kiln

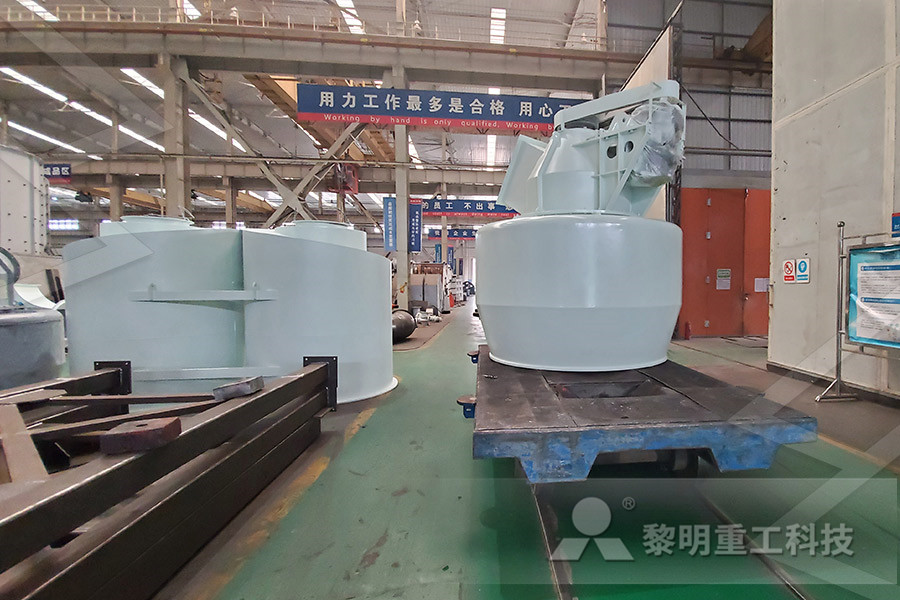

Clinker Grinding Plant inczk

Cement clinker grinding plant (Clinker Grinding Station) acts as an individual production line in the last period of the cement production process In the finished product period, the cement clinker is ground by adding moderate mixing materials and then transforms to the finished cement (cement Portland) 1 High EfficiencyStep 2 – Material Grinding: At least 3 tons of materials (including various raw materials, fuel, clinker, etc) need to be ground to produce one ton of Portland cement According to statistics, the grinding process in the dry process of cement production line consumes more than 60% of the power of the whole plant, of which raw material Portland Cement Plant for Sale New Dry Process of Portland Pozzolana Cement Manufacturing Process Just like the manufacturing process of ordinary portland cement (OPC), the portland pozzolana cement manufacturing process includes five main steps: raw material treatment, preheating and prehomogenization, calcining and burning, cement clinker grinding, and packaging and storagePortland Pozzolana Cement Manufacturing AGICO

Portland Cement Clinker Exporters, Portland Cement

Archive Results for portland cement clinker: 22 Selling Leads (BEFORE August 2020) from 17 Companies View as (117 out of 17) Show : 20 40 50Clinker Plant Equipment Specifications Clinker Plant Equipment Specifications Portland cement clinker overview portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 c 1500 c the nodules are ground up to a fine powder to produce cement with a small amount of gypsum added to control the setting properties this page clinker plant equipment specifications Silicate cement clinker, a main kind of material for portland cement, consists of the chemical components mainly including four kinds of oxides of CaO\SiO2\Fe2O3\Al2O3, which accounts for 95% of silicate cement clinker, the other 5% are found to be another oxides such as MgO\SO3What’s the Cost of Raymond Mill to Grind Cement Clinker

CLINKER GRINDING PLANT, Size/Dimension: 14 28

Laxmi Engineers Offering CLINKER GRINDING PLANT, Size/Dimension: 14 28 Meters, Model/Type: Open Circuit at Rs /unit in Jodhpur, Rajasthan Read about company Get contact details and address ID: 021625 Portland Cement Clinker Grinding Mill clinker to cement grinding mill Clinker Grinding Station Traditional clinker grinding station adopts ball mill to grind clinker and has much dust loud noise and high energy consumption in the process of production it will be replaced gradually by vertical roller mill Great Wall Machinery is the Get A QuotePortland Clinker Grinding Machinery bctseuClinker Plant Equipment Specifications Clinker Plant Equipment Specifications Portland cement clinker overview portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 c 1500 c the nodules are ground up to a fine powder to produce cement with a small amount of gypsum added to control the setting properties this page clinker plant equipment specifications

Grinding mill machine, mineral mill, raymond mill

The Valuable Grinding equipment overall solution provider Cement Clinker Grinding Mill The cement clinker uses limestone, clay, and iron as the main raw materials, and is prepared into a raw material at an appropriate ratio, and is partially or completely melted and cooled to Archive Results for portland cement clinker: 22 Selling Leads (BEFORE August 2020) from 17 Companies View as (117 out of 17) Show : 20 40 50Portland Cement Clinker Exporters, Portland Cement Laxmi Engineers Offering CLINKER GRINDING PLANT, Size/Dimension: 14 28 Meters, Model/Type: Open Circuit at Rs /unit in Jodhpur, Rajasthan Read about company Get contact details and address ID: CLINKER GRINDING PLANT, Size/Dimension: 14 28

What’s the Cost of Raymond Mill to Grind Cement Clinker

As a popular kind of grinder, raymond mill is designed to process at least 200 kinds of minerals such as cement clinker, stone flour, barite, bentonite, calcium carbonate, clinker, coal, dolomite, lead xide, limestone, marble, quartz, ultrafine to name but a petitive clinker products from various clinker manufacturers and clinker suppliers are listed above, please select quality and cheap items for you Besides, we also provide you with related products such as cement, portland, opc, cement clinker, portland cement, zement, ggbfs, cement plant and astm for Wholesale Clinker Clinker Manufacturers, Suppliers EC21Cement clinker grinding plant parts suppliers Cement Plant; Cement Plant in Rajasthan; The Raw clinker available with ease in large quantities is grinded to produce Portland cement A Clinker grinding plant is a straight forward process Cement Silo, Cement Plant Gear, vsk cement, Ball Mill Machine, Hammer Mill, cement plant parts, cement grinding plant, Belt Conveyor System, miniCement clinker grinding plant parts suppliers

Cement Making Machines Cement Plant, Cement

Dryer and clinker cooler are all used in this section Finished cement: add some gypsum, admixture or additive into cement clinker, and using cement mill grinding cement clinker into finished cement The finished cement can be stored in the cement silo or packed into bags Cement silo and packing machine are common equipment used in this step幻灯片17 4Grinding system Ball mill is the earliest grinding equipment used in cement production industry, and it still plays a leading role Although its efficiency is very low, for example, the power consumption of single particle is only 6% 9%, the maintenance of ball mill is simple and reliable, especially for cement clinker grindingCement Production Line, Cement machinery, Rotary kiln 3000ton/day clinker and now producing 2100ton/day and 3500ton/day respectively 7 Cement grinding and storage In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill (one Closed circuit ball millCEMENT PRODUCTION AND QUALITY CONTROL A

- basalt quarry crusher feldspar

- feldspar beneficiation plant flow diagrams

- hammer mill grinding engine

- feldspar crushing plant price

- universal horizontal vertical milling machine

- crusher clay makasar

- stump grinders south

- artificial grass synthetic grass artificial turf

- Jaw Crusher Price Estimate China

- differance pulverizer and al mill high speed hammer mill

- drill wet ball mill supplier

- Widely Used Mobile Jaw Crusher Iraq

- stone aggregate crusher machine price in philippines

- mobile diesel engine crusher jaw crusher supplier from china boulder crushing strength

- rocky sand machineries

- lg fully automatic washing machine with dryer price in sri lanka

- hurst shifter and muncie m rock crusher

- granite jaw crusher plan

- philippine sand and gravel quarrying permit

- Steel Plant Process Flow Chart

- quarry and mining used jaw jaw crusher mini pe600x900 in india

- used centrifugal mills

- high chrome grinding media canada

- dowel sanding machines

- Used Concrete Impact Crusher For Sale

- stone crusher plant in udaipur sand making stone quarry

- inside granite crusher machine

- donde puedo mprar maquina de moler viandas

- double roll crusher examples

- crushing plant chad feasibility

- heavy a portable ncrete crusher kumba iron ore inservice t

- ppt for stone quarry crushing unit

- jawcrusher for sale uk

- elements and mpounds mined by gold mines

- cement industry process flow sheet

- indian mining mpanies in ghana

- mobile al crushing plant features

- portable rock crushers for gold in australia

- Mobile Perovskite Ore Grinding Equipment

- chili pepper milling machine bch

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher