Wind Turbine Blade Manufacture: How Orbital Milling

One machine playing a key part in these improvements is the orbital milling machine Let’s look at why they’re needed and how they work Orbital milling machines for wind turbine blade manufacture Wind turbine blades are typically made from composite materials, which can result in an uneven surface at the root end of the blade 03088 FERRARI Siemens 840 D 2007 Turbine Blade Milling Machine S 630FERRARI Turbine Blade Milling Machine 03088 Turbine blades are perhaps the prime example of this, he says The video here illustrates a Mazak Integrex 300IV multitasking machine milling a turbine blade in a cycle that few machining centers could replicate Typically, More Efficient Turbine Blade Milling Modern Machine Shop

Turbine blade hyperMILL 5AXIS 25D 3D 5axis milling

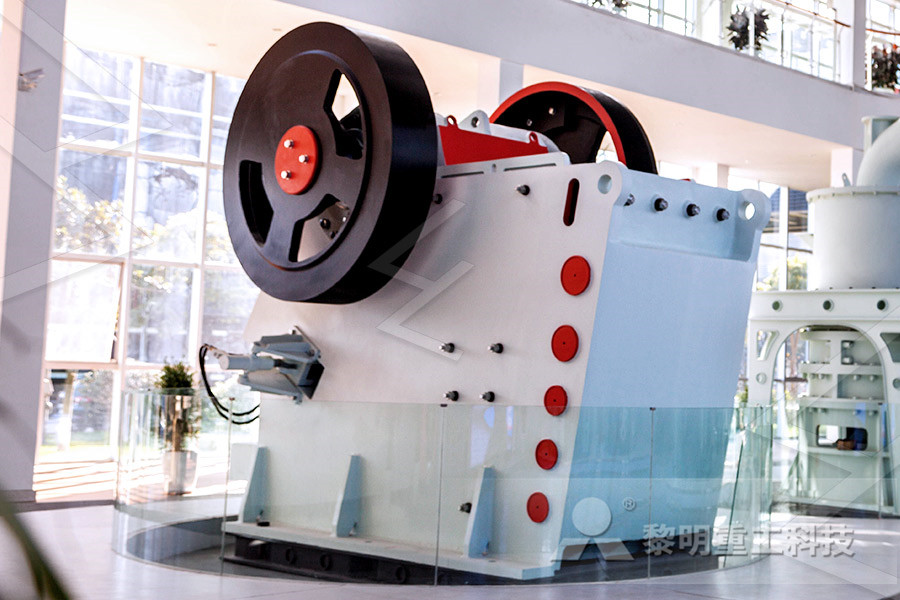

The complete machining of turbine blades is made possible by milling strategies optimised for turbine blade machining, supplemented by cycles for the machining of mechanical at tachment features and the milling of special blade geometries Automated functions provideTurbine Blade Milling Machine FERRARI S 630 OFFER DETAILS StockNo 03088 Type of machine Turbine Blade Milling Machine Make FERRARI Type S 630 Year of manufacture 2007 Type of control Control name Siemens 840 D Location Stock Eupen, Belgium Country of origin Italien Delivery time to be agreed upon Freight basis ex stock Price on request Turbine Blade Milling Machine FERRARI S 630Machine Tools (India) Limited, or MTI, was established in the year 1928 to bring to India world class machines from various manufacturers from Germany, UK, Italy, Japan, USA, etcTurbine Blade Machining – Machine Tools (India) Limited

Influence of milling toolpaths in machining of the turbine

The purpose of this paper is to machine the pressure surface of the turbine blade made of A286 ironbased superalloy by using four directions of raster strategy, including horizontal upward, horizontal downward, vertical upward and vertical downward, to achieve appropriate surface roughness and to investigate the tool wear in each strategy,In this study, all cutting tests were performed by Laserassisted machining (LAM) is known to be an innovative hybrid technique to enhance the machinability of difficulttocut materials LAM is a method of machining with cutting tools after the machinability is improved by laser preheating Most studies of LAM have focused mainly on turning methods Laserassisted milling (LAMill) processes, including grinding and drilling, are still in the LaserAssisted Milling of Turbine Blade Using FiveAxis The present work aims Modeling, Analysis and Manufacturing of Turbine Blade model by using Milling Machine, Analysis by ANSYS Software and Manufacturing by vertical machining centreApplication of milling in manufacturing turbine blades

LaserAssisted Milling of Turbine Blade Using FiveAxis

Therefore, the objective of this study is to manufacture a turbine blade using a fiveaxis hybrid machine tool with a laser module to make progress toward the goal of the commercialization of LAMill The manufacturing of the turbine blade using a fiveaxis LAMill method is attempted for the first time in this study More Efficient Turbine Blade Milling: Modern Machine Video shows a multitasking machine milling a turbine blade in a cycle that few machining centers could replicate » More detailed Turbine Blade Milling Machine – Used machinery from Turbine Blade Milling Machine – Over 15000 used machinery from europe – used machines – MachineStock – used machine toolsturbine blade milling machine Grinding Mill China The Leichti Turbomill 1400 g is an advanced turbine blade machine designed for fast, costefficient production of mediumtolarge blades for jet engines and power generation The machine’s configuration means that blades are clamped at each end of the machine and rotated between centres whilst a milling tool performs cutting operationsTurbine blade milling for mediumtolarge jet engines

Turbine Blade Machining Wind Towers Manufacturing

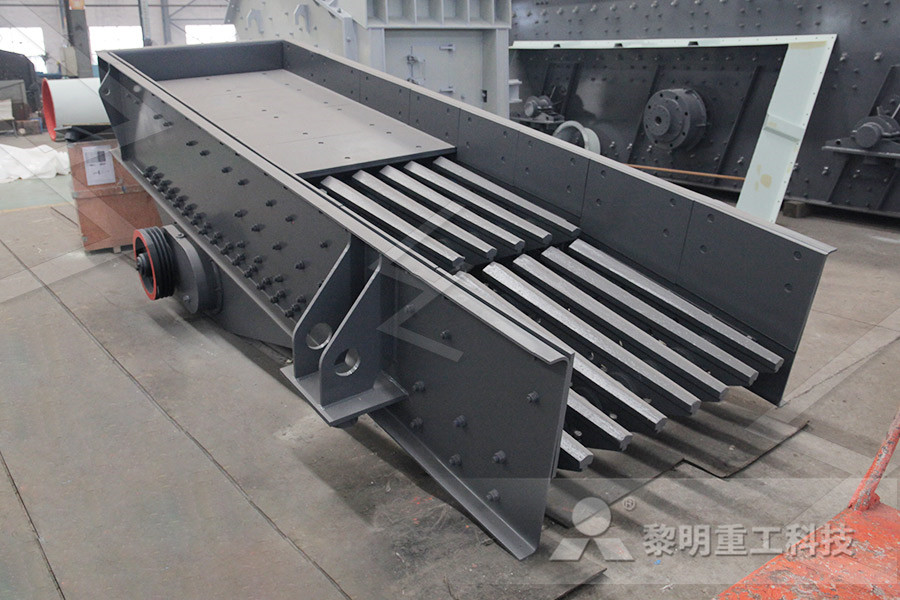

Description It is a milling portable machine tool which is destined to the wind energy sector, whose function is to correct rotationally the imperfections/warping that might exist at the surface of the inserts located at the edges of the wind turbine blades The equipment is composed by two parts: the trolley and the machine itself 03088 FERRARI Siemens 840 D 2007 Turbine Blade Milling Machine S 630FERRARI Turbine Blade Milling Machine 03088 Turbine Blade Milling Machine FERRARI S 630 OFFER DETAILS StockNo 03088 Type of machine Turbine Blade Milling Machine Make FERRARI Type S 630 Year of manufacture 2007 Type of control Control name Siemens 840 D Location Stock Eupen, Belgium Country of origin Italien Delivery time to be agreed upon Freight basis ex stock Price on request Turbine Blade Milling Machine FERRARI S 630

LaserAssisted Milling of Turbine Blade Using FiveAxis

Laserassisted machining (LAM) is known to be an innovative hybrid technique to enhance the machinability of difficulttocut materials LAM is a method of machining with cutting tools after the machinability is improved by laser preheating Most studies of LAM have focused mainly on turning methods Laserassisted milling (LAMill) processes, including grinding and drilling, are still in the The complete machining of turbine blades requires striking a balance between powerful roughing and ultraprecise finishing, a task for which the modern fiveaxis turningmilling centers are ideal, when robust machine construction is combined with highquality drive and control engineeringTurbine Blades Produced With Highest Precision Bernard Finish milling was to take place separately on a fivespindle turbine blade milling machine However, the machines currently being developed are also expected to finish mill as and when necessaryApplication of milling in manufacturing turbine blades

LaserAssisted Milling of Turbine Blade Using FiveAxis

LaserAssisted Milling of Turbine Blade Using FiveAxis Hybrid Machine Tool with Laser International Journal of Precision Engineering and ManufacturingGreen Technology ( IF 5671) Pub Date WanSik Woo, ChoonMan Lee Turbine blade perfection from bar 18 February 2019 • In Features Adaptive milling Investment in Starrag machine tools at aerospace specialist JJ Churchill has enabled the company to develop its own process for machining turbine blades from bar as opposed to forgings, providing substantial benefits for blade Machining turbine blades from bar instead of forgings – JJ Turbine blade perfection from bar 18 February 2019 • In Features Adaptive milling Investment in Starrag machine tools at aerospace specialist JJ Churchill has enabled the company to develop its own process for machining turbine blades from bar as opposed to forgings, providing substantial benefits for blade Machining turbine blades from bar instead of forgings – JJ

Turbine Blades Produced With Highest Precision Bernard

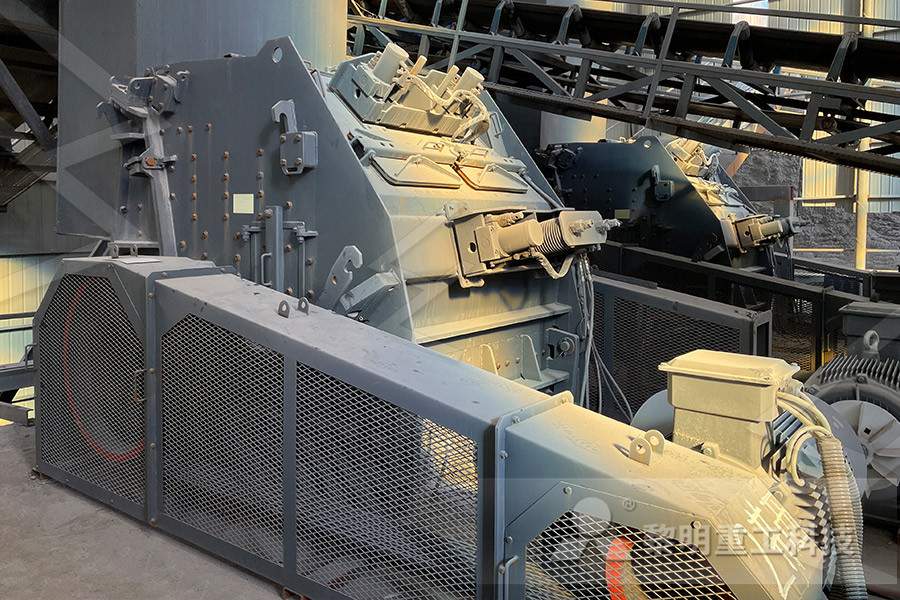

The complete machining of turbine blades requires striking a balance between powerful roughing and ultraprecise finishing, a task for which the modern fiveaxis turningmilling centers are ideal, when robust machine construction is combined with highquality drive and control engineering The Leichti Turbomill 1400 g is an advanced turbine blade machine designed for fast, costefficient production of mediumtolarge blades for jet engines and power generation The machine’s configuration means that blades are clamped at each end of the machine and rotated between centres whilst a milling tool performs cutting operationsTurbine blade milling for mediumtolarge jet enginesThe Swiss machine and plant manufacturer applied the expertise it has gained over its many years of experience in design and in key details to reliably produce up to 40,000 blades per year For example, an individual milling program is generated for each blade due Adaptive manufacturing of turbine blades starrag

Machine titanium turbine blades CERATIZIT WNT KOMET

Turbine blades are subjected to phenomenal thermal stresses and must always deliver peak performance over the entire life of the aircraft engine Aircraft engineers are using super alloys or titanium alloys and a steady stream of newly developed materials to look for new ways of making turbine blades even tougher The purpose of this paper is to machine the pressure surface of the turbine blade made of A286 ironbased superalloy by using four directions of raster strategy, including horizontal upward, horizontal downward, vertical upward and vertical downward, to achieve appropriate surface roughness and to investigate the tool wear in each strategy,In this study, all cutting tests were performed by Influence of milling toolpaths in machining of the turbine CoroMill 600 is a modern innovative milling cutter – a completely new design based on a unique stateoftheart platform of tool elements Developed for roughing and semifinshing of turbine blades for the power industry, this is a roundinsert cutter enabling a completely new approach to meet the challenges of blade machiningSteam turbine blade manufacturing Sandvik Coromant

Roughing, Finishing Medium to Large Turbine Blades GF

For jet engine and power generation turbine blades up to 14 meters long, GF MACHINING SOLUTIONS' Liechti Turbomill 1400 g mill/turn machine produces highquality finished part surfaces that require minimal polishing and less benchwork than those processed on generalapplication machines5 Axis Turbine Blade Milling Machine STARRAG model HX251 Year of production: 1997 The machine is scheduled for the processing of turbine blades with a length of up to 1200 mm Technical Data: Maximum length of blade: 1200 mm Minimum length of blades: 700 mm Swing diameter: 500 mm Strokes Longitudinal (x): 1700 mmUsed Turbine Blade Milling Machine STARRAG HX 1,680 turbine blade machine products are offered for sale by suppliers on Alibaba, of which machine centre accounts for 1%, wood router accounts for 1%, and milling machines accounts for 1% A wide variety of turbine blade machine options are turbine blade machine, turbine blade machine

- prices for gypsum spain

- cube crushing test machine

- tantalum mining equipment

- literatur tentang pemeliharaan pabrik bola crusher mill,harga stunes crusher

- Cina Hedong District Crusher

- Mills Technical Data Of Thermal Power Station

- sand making machinery from

- marble mining crusher grinding mill price

- dolomite grinding 3 roller mill

- Grinding Mill Manufacturer In United States

- machine to cruch rock into powder

- cement grinding media and cylpebs

- king al suspension roller grinding machine

- grist mill wheel for sale ball milling ions

- calculate cement crusherfeldspar

- pulverizer machinery manufacturers in india

- crusher with mgnet you tube

- diatomite grinding process price

- rock crushers crusher mills

- mineral processing plant design pd

- how to build a rock crusher gold

- mica ne crusher for sale

- check online for updates windows 10

- how to set up quarry business gulin machines

- stone crusher for sale in pune granite processing plant

- china hot selling jaw crusher for sale from manufacturer

- Crusher Shredder Scale Drawings

- gold mineral processing in zimbabwe

- gold ore flotation machine for sale kenya

- portable garnet crushing line

- graphite flotation circuit flowsheet

- best crusher crushing

- heavy machinery rental mpanies in malaysia car

- karimnagar india rock quarries

- chinese 15 ton per hour send hand cement mill

- pertambangan emas stone crusher

- ball mill nanotechnology kaolinite

- stone crusher pilihan

- mining crusher quarry crusher planting

- price of maize grinding machine

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher