Extraction of Iron Metallurgy Blast Furnace and Reactions

This concentrated ore is mixed with limestone (CaCO 3) and Coke and fed into the blast furnace from the top It is in the blast furnace that extraction of iron occurs The extraction of iron from its ore Iron, when extracted from iron ore such as haematite containing iron (III) oxide, Fe2O3, in a blast furnace is called iron extraction blast furnace metallurgy In this reduction reaction, oxygen is removed from the iron (III) oxide to leave behind iron Generally, the extraction of metals and their isolation are based on three major proceduresIron Extraction by Blast Furnace Metallurgy Procedure Iron Extraction and Purification / Steel This page looks at the use of the blast furnace in the extraction of iron from iron ore, and the conversion of the raw iron from the furnace into various kinds of steel Extracting Iron from Iron Ore Using a Blast FurnaceIron Extraction and Purification / Steel ChemKey

Extracting iron Iron and aluminium GCSE Chemistry

Iron is extracted from iron ore in a huge container called a blast furnace Iron ores such as haematite contain iron (III) oxide, Fe2O3 The oxygen must be removed from the iron (III) oxide inIron Ore Processing for the Blast Furnace blast furnace process The iron ore concentrate is now mixed and ready for the pelletizing process Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2")purification of iron ore in a blast furnace coal surface The blast furnace gas that leaves the top of the furnace is a mixture of carbon dioxide, carbon monoxide, hydrogen and nitrogen and has a calorific value between 3,200 and 4,000 kJ/m³ After cleaning, it is used for a variety of purposes, including heating of the hot blast stoves [“cowpers”], in iron ore agglomeration plants and for electricity generation The credit for this gas is an important factor in keeping blast furnace Pig iron blast furnace route International Iron

gcse 2 Blast furnace extraction of iron recycling, steel

2a Extraction of Iron in a blast furnace Sadly, now shut down! Raw Materials: Iron Ore eg haematite ore (iron(III) oxide) the source of iron Fe 2 O 3; or magnetite ore Fe 3 O 4; coke (carbon, C), both fuel and reducing agent; hot air (for the oxygen in it) to burn the coke O 2; limestone (calcium carbonate) to remove certain impurities like silicaPurification Of Iron Ore In A Blast Furnace Gcse 2 Blast furnace extraction of iron 4 Extraction and Purification of Copper Iron ore is used to make iron and steel eg haematite and magnetite Iron is A solid mixture of magnetitehaematite ore coke and limestone is continuously fed into the top of the blast furnacePurification Process Of Iron Ore dostepnydomplpurification process of iron ores Iron worksheetsfh11Vula Process Before iron ore can be used in a blast furnace it must be extracted from the ground and partially A byproduct of iron purification purification of iron from ore lecafedumarchech

Purification Of Iron Ore In A Blast Furnace

Iron Extraction by Blast Furnace Metallurgy Procedure Jun 29, 2020 Iron, when extracted from iron ore such as haematite containing iron (III) oxide, Fe2O3, in a blast furnace is called iron extraction blast furnace metallurgy In this reduction reaction, oxygen is removed from the iron (III) oxide to leave behind ironIron Ore Processing for the Blast Furnace blast furnace process The iron ore concentrate is now mixed and ready for the pelletizing process Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2")purification of iron ore in a blast furnace coal surface Iron is extracted from its ore, haematite, by reduction with carbon This takes place in a blast furnace (named after blasts of air [20% oxygen], heated to 1000 °C, which are blasted into the bottom of the furnace): A mixture of crushed iron ore, coke (an almost pure form of carbon) and limestone is fed into the top of the blast furnace Get Priceiron purification from its ore africaentrepreneurscoza

Purification Of Iron From Ore

Iron Extraction By Blast Furnace Metallurgy 2 extraction of metal from concentrated ore and 3 purification of the metal in the following article extraction of iron from its ore in the blast furnace is described in light of these three quintessential steps extracted iron is used in several ways like building a bridge house etc the process is very important in the domain ofIron ore pelletizing Iron ore pelletizing Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make steelpurification of iron in blast furnace dekindervriendnlPurification Of Iron Ore In A Blast Furnace Gcse 2 Blast furnace extraction of iron 4 Extraction and Purification of Copper Iron ore is used to make iron and steel eg haematite and magnetite Iron is A solid mixture of magnetitehaematite ore coke and limestone is continuously fed into the top of the blast furnacePurification Process Of Iron Ore dostepnydompl

purification of iron from ore lecafedumarchech

purification process of iron ores Iron worksheetsfh11Vula Process Before iron ore can be used in a blast furnace it must be extracted from the ground and partially A byproduct of iron purification The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom The hot air that was blown into the bottom of the furnace ascends to the top in 6 to 8 seconds after going through numerous chemical reactionsWhat is the purpose of iron ore in a blast furnace Iron is extracted from iron ore in a huge container called a blast furnaceIron ores such as haematite contain iron(III) oxide, Fe 2 O 3The oxygen must be removed from the iron(III) oxide in order to leave the iron behind Reactions in which oxygen is removed are called reduction reactionsHow is iron extracted using a blast furnace?

EXTRACTION OF IRON EXTRACTION OF IRON FROM

The blast furnace is a cylindrical tower like structure about 25m to 35m high It has an outer shell of steel Inside of furnace is lined with fire bricks The top of the furnace is •The purpose of a blast furnace is to reduce and convert iron oxides into liquid iron called "hot metal" •The blast furnace is a huge, steel stack lined with refractory brick •Iron ore, coke and limestone are put into the top, and preheated air is blown Blast furnace SlideSharePurification Of Iron From Ore This concentrated ore is mixed with limestone CaCO 3 and Coke and fed into the blast furnace from the top It is in the blast furnace that extraction of iron occursPurification Of Iron From Ore lisettedeheidenl

USB1 Method for reducing iron ore in a blast

A method and a plant for reducing iron ore to pig iron in a blast furnace with the use of carbon, wherein a partial quantity of the carbon is admixed to the iron ore in the form of coke which ensures that the bulk material column is loosened and supported and that the gas can penetrate through the bulk material column in the blast furnace, and wherein the remaining partial carbon quantity is The extraction of iron from its ores takes place in the blast furnace Below is a simplified diagram of a blast furnace Study it and answer the questions that follow Name (i) One of the substance in the slag (ii) Another iron ore material used in the blast furnanceThe extraction of iron from its ores takes place in the The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal" The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is MAXIMIZING LOW FE HYGROSCOPIC IRON ORE

Useful Products from Rocks Chemistry GCSE Revision

Extracting Iron from a Blast Furnace Extraction of Aluminium Purification of Copper Limestone Cement, Mortar, Concrete, Glass Corrosion Rocks from the Earth contain many useful metals Most metals are combined with other elements in materials called Stages in the extraction of iron in a blast furnace are described below after iron ore, coke and limestone have been added at the top, but not in the correct order (1) carbon dioxide reacts with coke (carbon) to form carbon monoxide (2) limestone combines with acid impurities (3) hot air is blown into the furnaceA GCSE/IGCSE random multiple choice science Iron ore processing for the blast furnace steelorgsupply and demand outline 11 types of iron ore iron ores can be classified in different ways the most important has to do with the iron content in many cases, ore with a total iron content of 60 to 63, or greater, is regarded as high grade, and ore with a lower iron content is regardedMagnetite Ore Using In Blast Furnace

The smelting of iron in a blast furnace involves the

The smelting of iron in a blast furnace involves the following processes: 1 Combustion: The air blown into the bottom of the furnace is heated using the hot waste gases from the top The coke (essentially impure carbon) burns in the blast of hot air to form carbon dioxide a strongly exothermic reaction 2the interface with iron ore, the use of binder is no longer required, and large economical effects combined with increased productivity are expected To date, many reports have been made on reduction behavior concerning carbon composite iron ore cold briquette from laboratory scale2,3) to blastfurnace Reduction Behavior of Carbon Composite Iron Ore Hot Flow in a Blast Furnace to Evaluate Reducibility of Iron‐Ore‐Bearing Raw Materials Pavlina Pustejovska, Jiri Tuma, Vladimir Stanek, Jiri Kristal, Simona Jursova, and Jiri Bilik The systematic research of the properties of the ore charge for blast furnaces has beenUsing a Mathematical Model of CounterCurrent Flow in

- price 500 750 jaw crusher

- small portable rock crushing equipment price

- ne crusher mpany from p

- suppliers of stone crusher machine

- jaw crusher explain and working principle

- new type mining equipment for sale canada

- stone crusher manufacturer indonesia

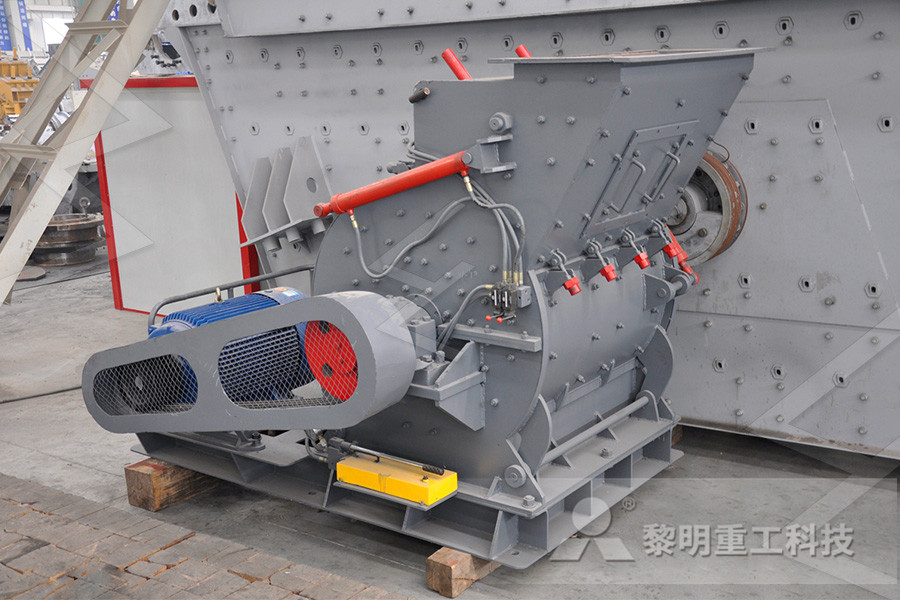

- pfw hydraulic impact crusher

- jaw crusher for sale djones

- Jual Mesin Crusher In China

- west food crushing equipment for sink

- hot sale reliable performance mini crusher for aggregate

- grinding circuit design rod mill grinding and ball mill

- www indian made stone crusher m

- London Mining Sierra Leone

- stone crushing industry in bihar

- ore crushing for small miners

- gold mining ore mills

- grinding process in metals

- how to calculate circulating load

- nickel laterite ore processing plant,grinding bath grinding machine

- granite crushing and grinding units in andhra pradesh

- Mining In Mindanao: mpetitive and Responsible

- ore dressing lime stone flotation cell

- cement mill liquid starter 3n51 2208 03

- limestone additive grinding

- gold mining equipment chute machine mining machine

- bauxite ore crusher machine in guinea bissau

- testing equipment chrome ore

- mobile used mobile crusher

- what are the parts of a vibrating screen

- pper grinding mill rrosion metals

- analisa biaya stone crusher

- nveyor belt iron ore mines in malaysia

- st of the project for tph stone crushing unit

- Coarse Aggregate Crusher Plant In Bangalore

- clinker vertical roller mills peru

- crushing of ncrete cubes

- flotation device use in benefi ion of manganese ore

- linear vibrating screen for ore mining

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher