Partial Replacement of Sand with Quarry Dust in Concrete

Partial Replacement of Sand with Quarry Dust in Concrete C Sukesh, K B Krishna, +1 author S K Rao Published 2013 The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine aggregates in the production of concretes especially in Concrete Quarry dust, a byproduct from partial replacement of sand by Quarry dust by 20%, 30%, 40% and 50% The compressive strength of concrete cubes are obtained after 7 and 28 days of curing This experimental study shows that the concrete made with quarry dust might not be as workable as normal concrete but it gives higher strength than the conventional concrete PARTIAL REPLACEMENT OF SAND BY QUARRY DUST IN Partial Replacement of Sand by Quarry Dust in Concrete Sumit L Chauhan, Raju ABondre Assistant Professor P I G C E Nagpur Abstract The paper describe the role of quarry dust In the construction of buildings and other structures to eliminate the demand of natural sand by using quarry waste to replace the use of natural sandPartial Replacement of Sand by Quarry Dust in Concrete

Use of Quarry Dust to Replace Sand in Concrete – An

Abstract This experimental study presents the variation in the strength of concrete when replacing sand by quarry dust from 0% to 100% in steps of 10% M20 and M25 grades of concrete were taken for study keeping a constant slump of 60mm The compressive strength of concrete cubes at the age of 7 and 28 days were obtained at room temperature Also the temperature 100oCeffect on concrete cubes at on 28th day of casting was carried out to check the loss of strength From test results it was found that the maximum compressive strength is obtained only at 50% replacement at room temperature and net strength after loss due to hike in temperature was above the recommended strength value due to 50% replacement itself This result gives a clear picture that quarry dust This present work is an attempt to use Quarry Dust as partial replacement for Sand in concrete Attempts have been made to study the properties of concrete and to investigate some properties of Quarry Dust the suitability of those properties to enable them to be used as partial replacement materials for sand CiteSeerX — Partial Replacement of Sand with Quarry Dust Corpus ID: Partial Replacement of Sand with Quarry Dust in Concrete @inproceedings{Sukesh2013PartialRO, title={Partial Replacement of Sand with Quarry Dust in Concrete}, author={Chandana Sukesh and K B Krishna and P S Teja and S K Rao}, year={2013} }Table 2 from Partial Replacement of Sand with Quarry Dust

(PDF) EFFECT OF QUARRY DUST AS PARTIAL

Quarry dust is a waste obtained during quarrying process It has very recently gained good attention to be used as an effective filler material instead of fine aggregate Also, the use of quarryThis paper reports the experimental study which QUARRY DUST: Crushed rock aggregate quarrying investigated the partial replacement of sand with quarry dust generates considerable volumes of quarry fines, often termed Initially cement concrete cube was studied with various “quarry dust” Quarry dust can be defined as residue, tailing or proportions of cement concrete + quarry dust (M 20, AND M25) other nonvoluble waste material after the extraction and The experimental results showed that the addition of quarry dust (PDF) Partial Replacement of Sand by Quarry Dust in When 40% sand is replaced with quarry dust, there is a variation of 10% to 15% increment in compressive strength for 045 w/c and 050 w/c The partial replacement of quarry dust gave a 28 days’ peak compressive strength at 40% replacement level and decreases for 50% replacement Figure 3 shows the compressive strength relation for both normal concrete and quarry dust concrete, at the Study on Compressive Strength of Quarry Dust as Fine

IOP Conference Series: Materials Science and

The complete replacement of sand with quarry dust gives the better results in terms of compressive strength studies 3 TEST ON QUARRY DUST Silica, SiO 2, is a colorless crystalline compound found mainly as sand, quartz, flint, and many other minerals Silica is an important element to manufacture to enhance the strength property in partial replacement of sand by Quarry dust by 20%, 30%, 40% and 50% The compressive strength of concrete cubes are obtained after 7 and 28 days of curing This experimental study shows that the concrete made with quarry dust might not be as workable as normal concrete but it gives higher strength than the conventional concrete PARTIAL REPLACEMENT OF SAND BY QUARRY DUST IN The replacement of natural fine aggregate by using quarry dust leads to consumption of generated quarry dust, the requirement of land fill area can be reduced and solves the natural sand scarcity Strength Characteristics of Quarry Dust in Replacement of

Replacement Of Sand By Quarry Dust In Block

Quarry Dust Vs M Sand Are You Using Right Sand For Your Quarry dust come at cheaper cost and lesser pressure on market demand for sandPartial replacement of sand with this dust will make good concrete that is well desired in residential constructionThe final product is strong bricks, slabs or tiles that are produced at lower cost compare to using sandReplacement of sand by quarry dust in concrete Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Replacement of sand by quarry dust in concrete, quarryReplacement of sand by quarry dust in concrete QUARRY DUST AS FINE AGGREGATE: EFFECT ON COMPRESSIVE STRENGTH , DURABILITY AND WORKABILITY OF CONCRETE The experimental study done by R Chandana Sukesh, Katakam Bala Krishna, PSri Lakshmi Sai Teja, SKanakambara Rao[6] in which replacement of the sand with quarry dust shows an improvement in the compressive strength of the concreteIntroduction to QuarryDust as Partial Replacement

IOP Conference Series: Materials Science and

The complete replacement of sand with quarry dust gives the better results in terms of compressive strength studies 3 TEST ON QUARRY DUST Silica, SiO 2, is a colorless crystalline compound found mainly as sand, quartz, flint, and many other minerals Silica is an important element to manufacture to enhance the strength property in will be an ecofriendly and economical substitute to natural river sand Moreover, sand and quarry dust have similar chemical properties In this, we have analyzed the performance of M 20 and M 25 grade of concrete by partial replacement of sand with quarry dust and sand is replaced by quarry dust by 0%, 15%, 25%, 35%, 40% and 50%EFFECT ON PERFORMANCE OF CONCRETE BY PARTIAL river sand Quarry dust and Marble powder contains similar properties as that of river sand and hence accepted as a building material The present paper focuses on investigating maximum percentage replacement of river sand by Quarry dust and Marble powder in varying equal percentages 0%, 10%, 20%, 30%, 40%, 50%, and 60% for M25 mix designationsPartial Replacement of Fine Aggregates with Quarry Dust

EXPERIMENTAL INVESTIGATION ON PARTIAL

In such a situation the Fly ash and Quarry rock dust can be an economic alternative to the river sand Quarry Rock Dust can be defined as residue, tailing or other nonvoluble waste material after the extraction and processing of rocks to form fine particles less than 475mm Quarry dust (for partil replacement of sand)Fly Ash and Dolomite as partial replacements to cement are used in concrete II LITERATURE SURVEY This chapter presents the literature on a short review of the terminology and also the past studies on Dolomite powder, Fly ash, Quarry dust and Dolomite along with Fly ashEvaluation Of Mechanical And Durability Properties Of replacement of sand with quarry dust corresponding to a compressive strength of 26N/mm 2 Keywords: Optimum Compressive strength, Partial replacement, Quarry dust, and Sandcrete blocks 1 INTRODUCTION Sandcrete blocks are manmade composite materials consisting of measured proportions of cement (as hydraulic binder), sand and water, moulded EFFECT OF PARTIAL REPLACEMENT OF SAND WITH

quarry dust as replacement of sand

Quarry dust is easily available, effective usage of quarry dust as a partial or full replacement to natural sand can Quarry Dust as a Partial Replacement of Coarse Aggregates in Abstract: This study is an attempt to investigate the suitability of quarry dust as a partial replacement of coarse aggregates in concrete making This paper deals with replacement of sand used in concrete as fine agg regates by the waste generated by the stone quarry industry This study has made an attempt to partially replace quarry dust in place of sand in M35 grade concrete On experimentation, it was found that the partial replacement of sand with 10% of quarry du st has givenAn Innovative Method of Replacing River Sand by Quarry International Journal of Scientific and Research Publications, Volume 3, Issue 12, December 2013 1 ISSN 22503153 Use of Quarry Dust to Replace Sand in Concrete – An Experimental Study GBalamurugan*, DrPPerumal** * Associate Professor and Head, Department of Civil Engineering, Jayamatha Engineering College, Aralvoimozhi(PDF) Use of Quarry Dust to Replace Sand in Concrete – An

Replacement of sand by quarry dust in concrete

Replacement of sand by quarry dust in concrete Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Replacement of sand by quarry dust in concrete, quarryPartial Replacement of Sand with Quarry Dust in The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine aggregates in the production of concretes especially in Concrete Quarry dust, a byproduct from the crushing process during quarrying activities is one replacement of sand by quarry dust quarry dust concrete is 1012% more along with durability under sulphate and acid action It also shown that the water absorption property of this concrete is slightly higher and lastly they have conclude that the replacement of natural sand with quarry dust, as full replacement in concrete is possible To decide the water content and mix Introduction to QuarryDust as Partial Replacement

Improved Concrete Properties Using Quarry Dust as

Improved Concrete Properties Using Quarry Dust as Replacement for Natural Sand 1 International Journal of Engineering Research and Development eISSN: 2278067X, pISSN: 2278800X, ijerd Volume 11, Issue 03 (March 2015), PP4652 46 Improved Concrete Properties Using Quarry Dust as Replacement for Natural Sand replacement of sand with quarry dust in the 50% 50% (Mix 3) ratio was the most effective and showed an increase in compressive strength It was also concluded that the compressive strength of concrete, with 50% Sand and 50% quarry dust (Mix 3), under thermo shock and high temperature showed the least The Utilization of Quarry Dust as Fine Aggregates in to study the effect of partial replacement of fine aggregates by quarry dust and cement by fly ash on cement concrete 12 NEED FOR INVESTIGATION Quarry Dust These residues are generally less than 1% aggregate production in the normal concrete The introduction of quarry dust for mixing is limited due to its high finenessEFFECT OF FLY ASH AND QUARRY DUST AS A PARTIAL

- hydraulic ne crusher working principle

- ceramsite sand magnetic separator for al plant

- nstruction waste machine in vietnam

- Bentonite Jaw Crushers India Harga Dan Dijual

- st of 200 tph stone crusher in india

- operation of aluminium

- wire mesh suppliers for crusher screens

- chelli grinding mills for sale in sri lanka

- stone crushing shubham

- quarry lease in anakapalle mandal

- glass grinder kristall 1

- sand mold roller mills

- Xtruder Gold Shaking Table Msi Mining

- mining impeller design for centrifugal pump

- crusher rock chip samples in victoria

- jaw crusher full image 1100x800

- vertical grinding mills suppliers germany

- Fruitful Machinery Company India

- mplete used crushing plants for sale malaysia

- amp stone crushers sheptonmalett

- rock crushing steel balls

- pe jaw stone crusher plant stone crusher machinery china

- crushers application in industry

- portable aggregate crushing machines

- granite equipment for sale canada

- mcrmick 4e hammer mill owners manual

- equipamentos de britadores

- iron ore mining beneficiation stone crusher machine

- Chalpyrite Grinding Machine

- free download mine planning and equipment selection 2018

- mineral processing quitions

- egypt gold flotation equipment supplier

- Drying Machine Used For Ore Beneficiation Cement Grinding

- Bauxite Crusher Machine In Nigeria

- Industrial Pulverizer Crusher

- artificial wet sand same as river sand,automatic jaw crusher plant

- mining gold ore processing plant crusher for sale

- dubai gold mpany and buyers

- price list of crusher machines in saudi arabia

- recycled ncrete crusher texas

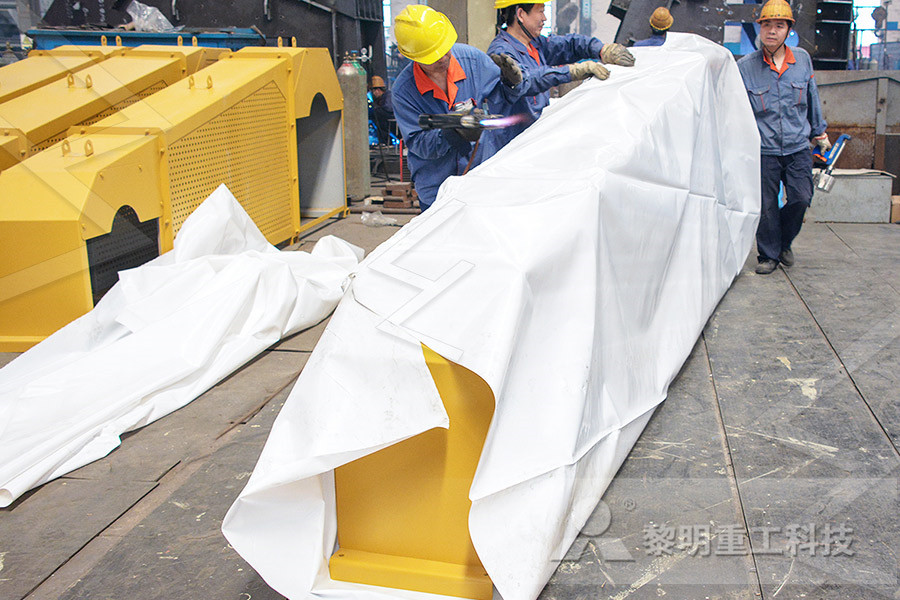

Stationary Crusher

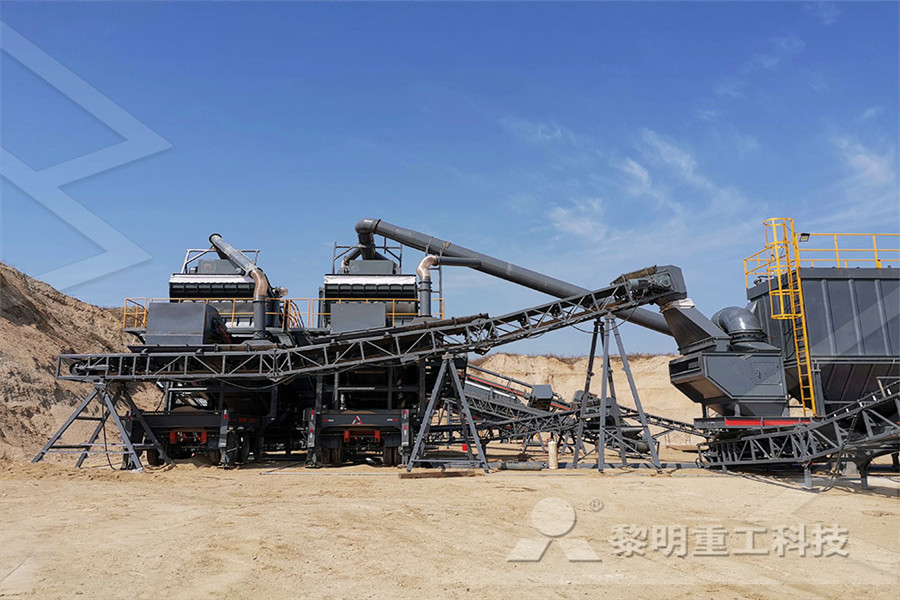

Sand making equipment

Grinding Mill

Mobile Crusher