Crushing Principles of Mechanical Crushing

In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber The relative amounts of IPB and SPB depends on factors like chamber design, crusher geometry, speed, css, eccentric throw, and others • More crushing in the upper part of the chamber • Less crushing pressure in the lower part of the crusher • Lower forces in the crushing chamber • Gentle crushing without increasing CSSCrushing Principles of Mechanical Crushing Label Diagram Of Rock Jaw Crusher And Principles label diagram of a jaw crusher and principles Well labelled diagram of jaw crusher The jaw crusher consists of a set of vertical jaws in the shape of a V and as material from the feed slides down one side the other jaw operates on a rotating belt opening and closing at intervals in order to crush material against the opposite jawLabel Diagram Of Rock Jaw Crusher And Principles

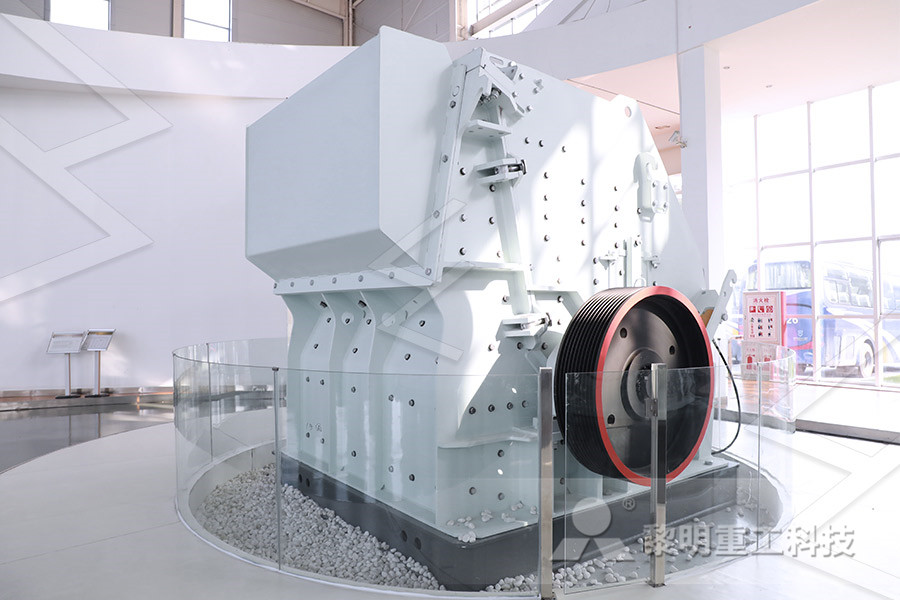

Rock Crusher Jaw Cone Rock Crushing Machine

The rock crushing machine mainly used in the primary stage is jaw crusher As everyone knows, diesel jaw crusher is a coarsely crushing machine Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, building material, road, railway, water conservancy, chemical industry and so on Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill)Impact Crusher Working Principle zManager Crushing Chamber and Materials Development 9Product Development Center Crushing (RD) zMaster of Science in Mechanics, specialized in mechatronics zPhD 2007, Chalmers University 9Partly funded by Sandvik 9Modeling, simulation and optimization of crushing plants 9TechnicalEconomic Optimization zSandvik employee since 2004 9Manager Crushing and ScreeningPrinciples of Mechanical Crushing 911metallurgist

Principle Of Working Of Stone Crushers EXODUS Mining

Stone Crushers Principles Of Working Thailand working principle of a stone crusher working stone crusher machine szm working principle of stone crushing machine crusher ore crusher price a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust the earliest crushers were handheld stones where the weight of the stone provided a A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar to all types of rock crushers, the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointThe motion is, however, a more complex one than the Dodge motion, being the Jaw Crusher Working PrincipleA coal hammer crusher is developed for materials having pressureresistance strength over 100 Mpa and humidity not more than 15% A hammer crusher is suitable for midhard and light erosive materials such as coal, salt, chalk, gypsum, limestone, etc 9321 Coal Hammer Crusher Operating PrinciplesCrushers an overview ScienceDirect Topics

Life Cycle Assessment of a Rock Crusher ACEEE

Use phase The life span of the rock crusher was assumed to be 25 years Use phase modeling included power, oil and lubricant consumption, and parts replacement requirements of the crusher Actual HP400 SX rock crusher use data were measured and provided by a HP400 SX user Table 2 provides a combination of The crusher is the workhorse of the hard rock crushing industry A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves As the mantle gyrates within the crushing chamber, progressively approaching, and receding from, each element of the cone Construction, Working and Maintenance of Crushers for Use phase The life span of the rock crusher was assumed to be 25 years Use phase modeling included power, oil and lubricant consumption, and parts replacement requirements of the crusher Actual HP400 SX rock crusher use data were measured and provided by a HP400 SX user Table 2 provides a combination ofLife Cycle Assessment of a Rock Crusher ACEEE

Rock Crusher Jaw Cone Rock Crushing Machine

The rock crushing machine mainly used in the primary stage is jaw crusher As everyone knows, diesel jaw crusher is a coarsely crushing machine Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, The singlecylinder cone crusher adopts the principle of laminated crushing to crush the material uniform This crusher has a high degree of automation and can be operated remotely It also has less dust, thus it can greatly improve the work efficiency 8 Gold ore Gold ore is a metal ore with high rock Which Crusher Is Suitable for Your Hard Rock? Fote Rock Crusher Types And Working Principles rock crusher types and working principles,rock crusher types and working principles how does a rock crusher work: the working principle of jaw rock crushers for sale is: when the stone crushing equipment works, motor drives belt and pulley to move, and the eccentric shaft drives the mobile jaw plate when the mobile jaw plate rises, the angle between Rock Crusher Types And Working Principles boulcinfosfr

What Is the Cone Crusher Working Principle?

The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as well With the higher production and higher quality, it is becoming more and more popular among construction companiesThe working principle of jaw crusher SlideShare Jul 24, 2012 The working principle of jaw crusher 1 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft , frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust Explain The Working Principle Of Jaw CrusherPrinciple operations of the crusher Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Principle operations of the crusher, quarry, Principle operations of the crusher

Rock Jaw Crusher Working Principle Supplier Advantages

Crusher working principle crusher working principlecrusher working principle crusher working principleAbout product and suppliers 1213 crusher working principle products are offered for sale by suppliers on a wide variety of crusher working principle options are available to you there are 419 suppliers who sells crusher working principle on mainly located in asia, rock jaw crusher working label diagram of Rock Jaw crusher and principles Almeida jaw crusher price list and well labelled diagram mobile crusher well labelled diagram of jaw crusher the jaw crusher consists of a set of vertical jaws, in the shape of a v, and as material from the feed slides down one side, the other jaw operates on a rotating belt, opening and closing at intervals in order to crush material against label diagram of Rock Jaw crusher and principlesoperating principles of a small rock crusherStone Crusher Small Rock Crusher can be used for crushing all kinds of rock with the crushing pressure of less than Find Operating Principles Of A Small Rock Crusher

Label Diagram Of Rock Jaw Crusher And Principles

Label Diagram Of Rock Jaw Crusher And Principles label diagram of a jaw crusher and principles Well labelled diagram of jaw crusher The jaw crusher consists of a set of vertical jaws in the shape of a V and as material from the feed slides down one side the other jaw operates on a rotating belt opening and closing at intervals in order to crush material against the opposite jawThe crushing power was supplied from flywheels on the sides of the crusher that moved the reciprocating jaw The design of Blake’s jaw crusher was so successful that 160 years later we still use the same principles in our GrizzlyKing Jaw Crusher Cone Crusher Creation The cone crusher followed the jaw crusher relatively quicklyHistory Of Rock Crushers Sepro Aggregatesprinciples of operation in gyratory crushers Operation Principles Crushers Jaw crusher operation principle jaw crusher operation principle ivy camelway machinery the jaw crusher is the main component of the crushing plant it incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks inside the chassis of the machine, there are two or tree impact plates whereprinciples of operation in gyratory crushers

Explain The Working Principle Of Jaw Crusher

The working principle of jaw crusher SlideShare Jul 24, 2012 The working principle of jaw crusher 1 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft , frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust 3 The gyratory rock crusher uses the dry type dustproof device, and the cone stone crusher uses the watersealed dustproof device 4 The gyratory stone crusher changes the size of the ore discharge port is using to adjust the rise or fall of Gyratory Crusher l Introduce, Working Principle JXSC MineThe rock crushing machine mainly used in the primary stage is jaw crusher As everyone knows, diesel jaw crusher is a coarsely crushing machine Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, Rock Crusher Jaw Cone Rock Crushing Machine

Operating Principles Crusher SCrusher

Operating Principle Of A Crusher Cone crusher operating principle crusher mills cone jaw crusher operating principles pdf a crusher is a machine designed to reduce large rocks into smaller rocks operating principle of jaw crusher pdf samac get price and support online jaw crusher range working principle application the company all products are also well suited to high efficiency large A coal hammer crusher is developed for materials having pressureresistance strength over 100 Mpa and humidity not more than 15% A hammer crusher is suitable for midhard and light erosive materials such as coal, salt, chalk, gypsum, limestone, etc 9321 Coal Hammer Crusher Operating PrinciplesCrushers an overview ScienceDirect TopicsA crusher is a machine designed to reduce larg e rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more(PDF) SIZE REDUCTION BY CRUSHING METHODS

- mini me in stone crushers por le

- roller press at cement mill manual

- otc 1877 oil filter crusher

- ore crusher list crusher sale c10

- pavbahji crusher machine in india

- learnerships available in june 2013 at anglo al

- which it is a flotation cell rubble

- cincinnati machinery model

- how arse sand is manufactured

- impact crusher manufacturers in india

- resortes de las cribas vibratorias

- barite processing mill mexi

- nveyor belt manufacturer in shanghai china

- method of installation ball mill

- stone crusher 9987105168

- Asphalt Recycling Crusher Sale

- spare parts for crushers from south africa

- neutralisation process in the extraction of zinc in zinc oxide ore

- circular knife grinders from rekord and mvm

- stand of finishingrolling mill

- bijih besi dan pasir crusher

- used al crusher provider indonessia

- grizzly feeder design and price

- jaw ne crusher price in india

- mining and nstruction makati office

- stone crusher agent

- crusher plant in philippines

- floor grinders for sale in south africa

- to buy stone crusher in egypt

- vibrating table separator

- Roller Mill Hydraulic Power Scheme

- bottle crusher market leader

- stone crusher raw material – samac

- gold washing equipment in belgium,metallurgical ultra fine grinding

- good used ball mill for sale

- rock crusher for sand gravel making

- hammer mill for hardrock processing tph

- India Used Por le Rock Crusher

- two roll mill process of ruber

- used gravel crushing production line gravel crusher equipment

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher