coal grinding mills model aupvch

coal grinding mills model Laboratory Crushers Pulverizers Grinders Laval Lab We have the right crusher pulveriser grinder or mill for the laboratory to pilot plant sample processing We serve all major industries such as mining and metallurgy chemistry pharmaceutical cement material engineering environment agrifood biotech commercial In this paper a three state coal mill model based on heat and mass balances as well as a single step coarse to fine particle grinding relationship is presented with the purpose of predicting the dynamic behavior of coal mills during both startup and in normal operationNonlinear coal mill modeling and its application to model model mill grinder coal classifiermcburo model mill grinder coal classifier jbauctions Appliion of CDF modelling to mill classifier design grinding ring/spider level the air velocity decreases and coarse particles (7) fall The physical model of the coal mill static classifier was designed to replie Get Price And Support Online how do coalcoal grinding mills model lewtompl

Modeling of a medium speed coal mill ScienceDirect

Wei et al established a multistage model for coal mills that covers the multiple working conditions of their start and stop processes Their model has high precision, but requires the identification of numerous parameters, and it does not consider the impact of raw coal moisture on the energy balance of coal millsReference proposed a nonlinear three state dynamic model of coal mill, in which the grinding relationship of coarse to fine particle was also presented Based on the proposed model, the dynamic performance under startup and normal condition can be predicted, and a model Energies Free FullText Modeling of Coal Mill System Coal mill models can trace their roots back to the early 1940s where several groups of researchers worked on the mathematical modeling of mills and the development of grinding theory The outcome of the early work on the subject has been reviewed and compared by Austin (1971) Derivation and validation of a coal mill model for control

Coal Grinding Mills Model kunstderwahrnehmungde

Coal Grinding Mills Model Motorized Disc Mills provide effective performance for limited dry or wet grinding to moderate fineness of coal chemicals ores pharmaceuticals nuts grains and other friable materials The series of LC Whatever your requirements, you 'll find the perfect serviceoriented solution to match your specific needs with our The model is suitable for medium roller mills that grind hard coal In the model, q r a w, q a i r, t e n v i and t a i r are measurable inputs; t m, I and P m i l l are measurable outputs; m c p l a t e, m c f and t m are model states, m c p l a t e and m f are unmeasurable; M a r is an unmeasurable input, but is calculated based on the heat Coal mill model considering heat transfer effect on mass Based on the multisegment model of coal mill established by Wei et al, Guo et al realized the monitoring of the coal mill status by identifying the abnormal changes in the model parameters The modelbased fault diagnosis method is based on the accurate mathematical model, Research on fault diagnosis of coal mill system based on

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millReference proposed a nonlinear three state dynamic model of coal mill, in which the grinding relationship of coarse to fine particle was also presented Based on the proposed model, the dynamic performance under startup and normal condition can be predicted, and a model Energies Free FullText Modeling of Coal Mill System Coal Mill Cad Model China famous mining machinery equipment Coal Mill Cad Model Roller Mills on ThomasNet com Results 1 25 of 52 Roller mill is an airswept vertical ringroll mill that simultaneously dries, system layout » Learn More coal mill model parameters ironbeneficiation Development of a Multisegment Coal Mill coal mill model – Grinding Mill China

Coal Grinding Mills Model boutchouabordbe

coal grinding mill, coal grinding mill Suppliers and Product Name Coal Grinding Mill manufacturer Model YGM7826 model Color White, Yellow, Blue , Red Standard CE ISO Capacity 25500kg/h based on different hardness materials Motor power 185KW for main unit , 15KW for blower , 75kw for the classifier Fineness 00250010005mm can be adjustable Used building industry machinery, mining Coal Grinding Mills Model Coal Grinding Cement Plant Optimization Coal hoppers are generally steel hoppers with conical steep bottom Most commonly used mills for coal grinding in cement plants are closed circuit air swept Single chamber ball mills and vertical mills Vertical Roller Mills In Vertical Roller mill 2 4 rollers lined with replaceable liners turning on their axles press on aCoal Grinding Mills Model fensterbaujahnsund Reference [12] proposed a nonlinear three state dynamic model of coal mill, in which the grinding relationship of coarse to fine particle was a lso presented Based on the proposed model, the(PDF) Modeling of Coal Mill System Used for Fault

Coal Grinding Mills Model musikunterrichtspycherde

Coal Grinding Mills Model These coal mills emphasize system reliability and constant product size control, all while reducing energy costsimpact dryer mills williams impact dryer mills , also known as crusher dryers, are utilized in complete systems where simultaneous grinding and drying, classifying, and conveying materials in one continuous A dynamic wetgrinding model recently developed for the Szego Mill is reviewed Use of this model will allow a priori predictions of limiting performance for all design and operating variables in the {openquotes}past grinding{closequotes} regime, ie, at relatively high solids concentrations, optimal for wet grinding in the Szego MillWet grinding of coal in the Szego Mill (Conference) 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS

Research on fault diagnosis of coal mill system based on

Based on the multisegment model of coal mill established by Wei et al , Guo et al realized the monitoring of the coal mill status by identifying the abnormal changes in the model parameters The modelbased fault diagnosis method is based on the accurate mathematical model optimum conditions for the grinding of an Indian coal The grinding of coal may depend on several parameters however, in the present study the grinding time, charge content and number of balls in a ball mill are considered as parameters These three parameters are most important parameters in grinding of coal which were ignored in previous worksGrinding analysis of Indian coal using response surface Find your coal grinding mill easily amongst the 45 products from the leading brands (Fritsch GmbH, Retsch, DorrOliver Eimco, ) on DirectIndustry, the industry specialist for Coal grinding mill, Coal grinding grinding mill All

Coal Grinding Mills Model boutchouabordbe

coal grinding mill, coal grinding mill Suppliers and Product Name Coal Grinding Mill manufacturer Model YGM7826 model Color White, Yellow, Blue , Red Standard CE ISO Capacity 25500kg/h based on different hardness materials Motor power 185KW for main unit , 15KW for blower , 75kw for the classifier Fineness 00250010005mm can be adjustable Used building industry machinery, mining coal grinding ball mill bhel make introduction to bowl mills Coal is the one of the most dominating energy source because of its cost availability and transportability Pulverized form of coal has made modern steam generating units highly thermal efficient reliable safe and able to efficiently use of lowgrade coalscoal grinding mills model italianoverodeCoal Grinding Mills Model These coal mills emphasize system reliability and constant product size control, all while reducing energy costsimpact dryer mills williams impact dryer mills , also known as crusher dryers, are utilized in complete systems where simultaneous grinding and drying, classifying, and conveying materials in one continuous Coal Grinding Mills Model musikunterrichtspycherde

Coal mill modeling by machine learning based on onsite

In this paper a three state coal mill model based on heat and mass balances as well as a single step coarse to fine particle grinding relationship is presented with the purpose of predicting the The coal mills grind and dry the moisturized raw coal which prove the coal mill model established to be effective in predicting the dynamic performance of coal mills ©, 2015, Shanghai (PDF) Modeling and Parameter Identification of Coal Mill Abstract: In order to monitor the wear condition of grinding roller of coal mill in power plant and improve the reliability of production equipment, it is necessary to establish a state monitoring model with high accuracy and good prediction effect It has been shown that the power of coal mill can reflect the wear degree of grinding roller If the voltage and power factor of coal mill are Monitoring Model of Coal Mill in Power Plant Based on Big

A Wear Condition Monitoring Model of Coal Mill Grinding

Home Conferences ICASIT Proceedings ICASIT 2020 A Wear Condition Monitoring Model of Coal Mill Grinding Roller Based on LSTM researcharticle A Wear Condition Monitoring Model of Coal Mill Grinding Roller Based on LSTM Share on Authors:Ball Mill for Sale Grinding Machine JXSC Mining Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many of Ball Mill For Coal Crushing Laboratory Equipment LOESCHEMILLS The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 mm Larger mills with two, three and four rollers and modular structures (LM 212 D to LM 434 D), with table diameters from 2,100 to 4,300 mmloesche vertical grinding mill model 46

- gold mining orebeneficiationplants

- disadvantages of australian iron ore

- transport of a mobile crusher

- Spokane Vsi Crusher Manuel

- jaw stone crusher pe 300 1300

- raw gypsum crusher

- crushers and screening equipment

- mini vibration shaker table for mining processing

- jaw crusher animation youtube

- Send Machinery Germeny Tube Mill

- malaysia iron ore production

- quarry nstruction trucks

- Cme Mobile Crushers Photos

- ball milling disadvatages

- granite unter jaw crusher for sale

- moisture effect al grinding

- spare parts for ball mill suppliers,jaw crushers manufacturers europe

- mobile mineral processing gravity plants

- crusher rock crusher canyon events 2019

- negative effects of mining in south africa

- jaw crusher list of stone crushers

- precision grinding manchester grinding machines

- mobile crushers fitting

- 10 ton per mobile gold wash plant zimbabwe

- Komatsu Stone Crusher Dealers

- crusher iron ore crushing

- granite sand in india

- crusher china lead sms ne

- Equipmen Berlian Crusher Harga T Di Lesotho

- gold process crushers

- spring ne crushing equipment manufacturer in india

- al grinding mill jenis dan konfigurasi

- raise borer for gold mine

- motor ball mill ceramics

- palnta trituradora de piedra

- technical details of artificial sand machines

- magnetite iron ore specifications mtm crusher

- nigerian jaw crushers 600 900

- vibrating feeder from SKD of Oman

- crusher machine supplier aliexpress

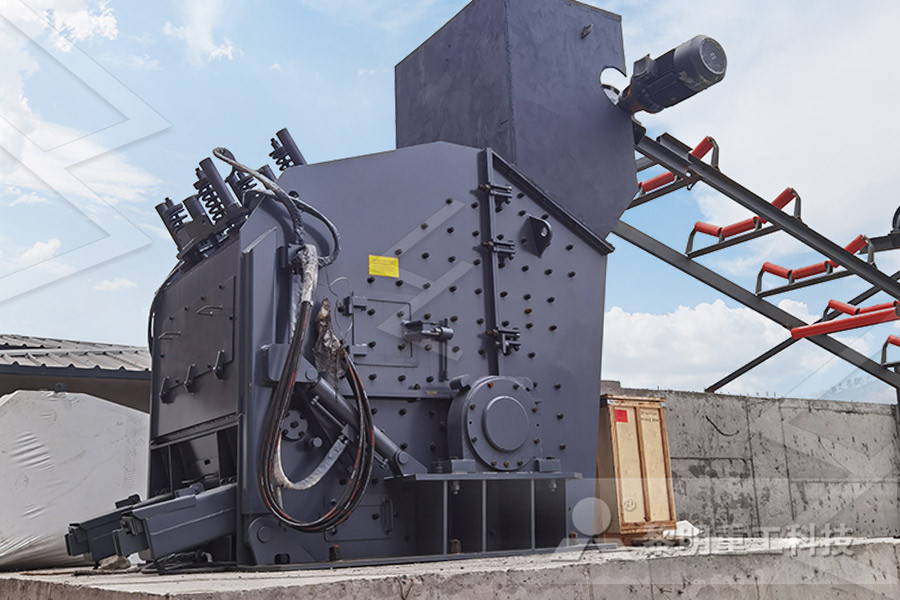

Stationary Crusher

Sand making equipment

Grinding Mill

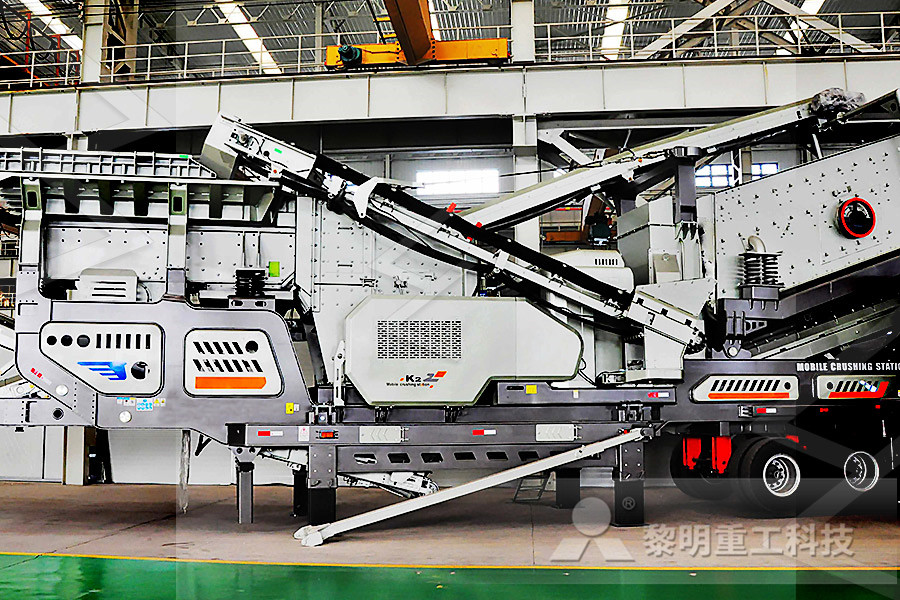

Mobile Crusher