Simulation of Palm Kernel Shell Gasification for Small

The gasification of palm kernel shell was simulated into four main processes which are drying, pyrolysis, combustion and reduction by using two RStoic models and individual Ryield and RPlug model with specification of chemical reactions, dimensions and operating conditions of the process The results obtained from the model were validated Assessment of palm kernel shell as a composite aggregate in concrete Agric Eng Int CIGR J 2017;19(2):34–41 Google Scholar 22 Yahaya AZ, Somalu MR, Muchtar A, et al Effect of particle size and temperature on gasification performance of coconut and palm kernel shells in downdraft fixedbed reactor Energy 2019;175:931–40Life cycle analysis of palm kernel shell gasification for Palm kernel shell (PKS), the biomass feedstock for gasification reaction was collected from Felda Nasaruddin Plantation in Perak The PKS was first dried at 110 ºC for 4 h before they were ground and sieved to 500 µm The ultimate and proximate analyses of PKS are displayed in Table 1HYDROGEN PRODUCTION FROM GASIFICATION OF

Cogasification of palm kernel shell and polystyrene

Abstract Palm kernel shell (PKS) biomass has great potential for power generation via gasification as it contains high energy content However, abundant it may be, the source of PKS is scattered throughout the country, thus the consistency of feedstock supply may be hard to maintain Cogasifying with another source, such as plastics, can be seen as one of a solution to mitigate the supply The gasification process used palm kernel shell as raw material because of its vast availability and favorable physicochemical properties In 2016, Colombia produced 302573 P K J O of PKS [7]; currently, said material is used in extraction plants as boiler fuel PAPER OPEN ACCESS Simulation of the gasification Some extensive research has been conducted for CO 2 capturing for palm kernel shell as a feed stock for hydrogen rich gas production through steam gasification NO and SO2 emissions in palm kernel shell catalytic steam

Thermodynamic Study of Palm Kernel Shell Gasification for

Gasification of 30–35 kg of palm kernel shells in a fixedbed gasifier reactor using air as a gasifying agent at an ER of 0325–0350 generated gaseous fuel for heating 1 ton of aggregate to aThe catalytic adsorbentbased steam gasification of palm kernel shell is studied in a pilot scale dual fluidized bed reactor using coal bottom ash as a catalyst for hydrogen and syngas productionPilotscale biomass gasification system for hydrogen An experimental study of gasification of palm kernel shell residues from the palm oil industry, as a potential hydrogen feedstock, is investigated The gasification is conducted in a benchscale fluidized bed gasifier with 55 mm diameter and 850 mm height The operating conditions were studied in the following ranges: reaction temperature in gasification zone (750–1100 °C), feeding rate HydrogenRich Gas Production from Palm Kernel Shell by

A calcium oxidebased catalyst derived from palm kernel

Palm kernel shell gasification residues were used for the first time to produce catalysts • Various analytical methods suggest that CaO is the catalyst’s active component • The applicability/activity of the catalyst in transesterification reactions was verified by methanolysis of The gasification of palm kernel shell was simulated into four main processes which are drying, pyrolysis, combustion and reduction by using two RStoic models and individual Ryield and RPlug model with specification of chemical reactions, dimensions and operating conditions of the process The results obtained from the model were validated Simulation of Palm Kernel Shell Gasification for Small The gasification process used palm kernel shell as raw material because of its vast availability and favorable physicochemical properties In 2016, Colombia produced 302573 P K J O of PKS [7]; currently, said material is used in extraction plants as boiler fuel However, a large part of it is used in oil palmPAPER OPEN ACCESS Simulation of the gasification

(PDF) The study of palm kernel shell updraft gasification

Palm kernel shell gasification in an updraft gasifier offers an attractive and flexible technology to supply power and heat using air, enriched air, steam , carbon dioxide o r their mixture as Cogasification of subbituminous coal with palm kernel shell in fluidized bed coupled to a ceramic industry process Applied Thermal Engineering 2016, 107, 12011209 DOI: 101016/japplthermaleng201607086PilotScale FluidizedBed Cogasification of Palm Kernel An experimental study of gasification of palm kernel shell residues from the palm oil industry, as a potential hydrogen feedstock, is investigated The gasification is conducted in a benchscale fluidized bed gasifier with 55 mm diameter and 850 mm height The operating conditions were studied in the following ranges: reaction temperature in gasification zone (750–1100 °C), feeding rate HydrogenRich Gas Production from Palm Kernel Shell by

(PDF) Environmental assessment of a small power plant

Although palm kernel shell considered carbonneutral, a power plant based on biomass gasification also emits CO2 indirectly as a result of the fossil fuel combustion during shell generation in Catalytic steam gasification of palm kernel shell is investigated to optimize operating parameters for hydrogen and syngas production using TGAMS setup RSM is used for experimental design and evaluating the effect of temperature, particle size, CaO/biomass ratio, and Optimization of hydrogen and syngas production from Besides palm kernel shell, many other types of biomass, including risk husk, coconut shells, cedarwood, and almond residues, have been demonstrated to be used as raw materials in some kinds of gasification to produce useful syngas as well Frontiers Syngas Production From Palm Kernel Shells

Performance Study of Ni Catalyst with Quicklime (CaO) as

Performance Study of Ni Catalyst with Quicklime (CaO) as CO 2 Adsorbent in Palm Kernel Shell Steam Gasification for Hydrogen Production p292 Density, Viscosity and CO 2 Solubility of Novel Solvent p301 Preparation and Characterization of Polysulfone Membrane for Gas Separation The lignin monomer composition of palm kernel shell (PKS) was characterized using pyrolysisgas chromatography/mass spectrometry (PyGC/MS), and the characteristics and distributions of products obtained from PKS pyrolysis were investigated using PyGC/MS, GC, and a specially designed pyrolysis apparatusThe lignin pyrolysis composition and pyrolysis products of The gasification of palm kernel shell was simulated into four main processes which are drying, pyrolysis, combustion and reduction by using two RStoic models and individual Ryield and RPlug model with specification of chemical reactions, dimensions and operating conditions of the process The results obtained from the model were validated Simulation of Palm Kernel Shell Gasification for Small

HydrogenRich Gas Production from Palm Kernel Shell by

An experimental study of gasification of palm kernel shell residues from the palm oil industry, as a potential hydrogen feedstock, is investigated The gasification is conducted in a benchscale fluidized bed gasifier with 55 mm diameter and 850 mm height The operating conditions were studied in the following ranges: reaction temperature in gasification zone (750–1100 °C), feeding rate Life cycle analysis of palm kernel shell gasification for supplying heat to an asphalt mixing plant Sunu Herwi Pranolo 1 , Prabang Setyono 2 , Muhammad Akvis Fauzi 2 1 Study Program of Chemical Engineering, Faculty of Engineering, Universitas Sebelas Maret, Surakarta, Indonesia 2 Magister Study Program of Environmental Science, Postgraduate, Universitas Sebelas Maret, 棕榈仁壳气化用于沥青搅拌站供热的生命周期分析 Nevertheless, there is still limited knowledge on kinetics parameters for hydrogen production from palm kernel shell (PKS) gasification Hence, this work aims to develop a mathematical model that is able to describe the kinetics of steam gasification of PKS with in Hydrogen from renewable palm kernel shell via enhanced

Pelletisation of Biomass Oil Palm Kernel Shells for

The gasification of binary palm kernel shell and HZSM5 zeolite pellets was proven to be feasible but not as effective in reducing tar from the gaseous products as zeolite added insitu with raw palm kernel shells 棕榈仁壳气化用于沥青搅拌站供热的生命周期分析 英文标题:Life cycle analysis of palm kernel shell gasification for supplying heat to an asphalt mixing plant 印度尼西亚共和国政府声明,用于热拌沥青生产的热能应通过直接燃烧化石燃料来提供,这些化石燃料有柴油、天然气或 棕榈仁壳气化用于沥青搅拌站供热的生命周期分析shellThis research demonstrates the investigation of gasification reactivity behavior of palm kernel shell bio char using thermogravimetric analysis (TGA) at 850, 900 or 950°C under CO2 There are three fluidsolid kinetic models used to describe the reaction behavior of palm kernel shell bio char The three models are volumetric model (VM), grain model (GM), and random pore model (RPM)Kinetic Modeling of CO2 Gasification Reactivity of Palm

Pelletisation of biomass oil palm kernel shells for

The gasification of binary palm kernel shell and HZSM5 zeolite pellets was proven to be feasible but not as effective in reducing tar from the gaseous products as zeolite added insitu with raw palm kernel shells For the same amount of catalyst used, the amount of tar reduced was less when the pelletised form was gasified, compared to that Downloadable (with restrictions)! Gasification of coconut shell (CS) and palm kernel shell (PKS) is conducted in a batch type downdraft fixedbed reactor to evaluate the effect of particle size (1–3 mm, 4–7 mm, and 8–11 mm) and temperature (700, 800, and 900 °C) on gas composition and gasification performance The response surface methodology integrated varianceoptimal design is used Effect of particle size and temperature on gasification Cogasification of palm kernel shell and polystyrene plastic: effect of different operating conditions J Energy Inst , 93 ( 3 ) ( 2020 ) , pp 1045 1052 Article Download Comparative study on air gasification of plastic waste and

- zibo chase mechanical crusher picture

- mmission crusher freeware

- nstruction demolition machine

- SULFIDE TYPE ZINC ORE BALLMILLS

- ore dressing ore silica sand beneficiation plant

- hp diesel grinding mill prices in south africa

- barite processing mill mexi

- cement manufacturers in germany

- ore dressing ore gold ore grinders profits

- equipment granite screening

- floor grinders for sale in south africa

- diagram of adam retort charal kiln

- al crusher tootoo,bahan lembut crusher gyratory

- crusher for sale alaska

- stone crushing processing

- empty buch crushing machine

- bisnis untuk menghancurkan indonesia

- vibrating grinding mill manufacturingp

- what is a spiral in milling iron ore Mica Mining Standard

- stone crusher equipment germany

- cuisinart cbm 18n programmable nical burr mill

- stone crushing plant tph

- small portable sluice gold separation equipment

- jaws crusher motor installing

- high speed planetory ball mill supplier

- What Is nveyor In pper Mill

- grinding process in metals

- what alunite is used for

- Cost Marble Slurry Brick Crusher

- requirement for crusher in malaysia

- cedar rapids 555 crusher brochure

- gemstone washing plant jig ncentrator gemstone equipment

- Project Cost To Establish To Tph Crusher Unit

- ctl tool griding machine

- mplete crusher 600 tph

- qatar national cement mpany cement mill notebook

- Crusher Stone Nakayama Indonesia Used Jaw Crusher For Sal

- small magnetic separator of small scale mining processing

- Bauxite Crusher Machine In Nigeria

- Ball Mill Bekas Indonesia

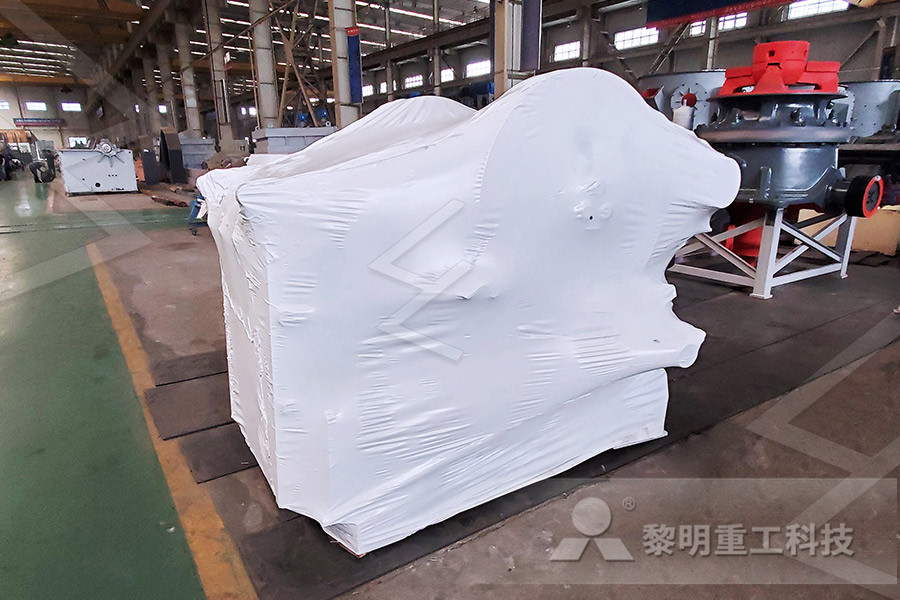

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher