gold flotation process air amount iramotorsco

gold flotation process air amount Froth flotation of phosphate rock ThinkIR University of Louisville froth of mineral, air, and water, and means of allowing fresh pulp to enter and treated and fair recoveries of copper, gold, and silver were made by separating the facial The addition of xanthate, in the amount usually found in flotation circuits, does not precipitate gold from a pregnant cyanide solution containing the normal amount of cyanide and lime PRIMARY SLIME Valueless slime, in addition to its detrimental effect in coating goldbearing sulphide, thereby limiting or preventing its flotationGold Flotation Mineral Processing Metallurgy 01 The gold ores suitable for the flotation process In the practice, the flotation method can be considered when the goldbearing ores have the following characteristics: The gold and sulfide are closely associated; Although most of the gold does not coexist with sulfide, a considerable amount of metal sulfide in the ore has formed a stable foam containing gold sulfide;gold flotation process Xinhai

Flotation of Gold and GoldBearing Ores ScienceDirect

1 Background The application of flotation on a reasonable scale within the goldmining industry commenced in the early 1930s following the introduction of watersoluble flotation collectors (specifically xanthates and dithiophosphate collectors) that allowed differential flotation of sulfide minerals (Weinig and Carpenter, 1937, Rabone, 1939, Richards and Locke, 1940, Taggart, 1945) A total recovery of more than 97% of the gold and silver is made by flotation, while the combined flotationcyanidation process gives an overall extraction Silver Gold Recovery Flotation ProcessGold Flotation Production Line Process Introduction The flotation meth od is a widel y used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many other ores where other processes are not applicable Flotation Gold Flotation Production Line,Gold Flotation Plant,Gold

Advancing flotation process technologies to maximise

A flotation process is one method used throughout the industry to recover gold It’s a very costeffective method for concentrating gold, and is a desirable process used for the upgrading of lowsulphide and refractory ore for further gold recovery treatment Froth flotation is a process The process needs small amount of oil and coal particles addition into the flotation slurry to enhance the gold recovery and it makes the method economically applicable The results of this investigation seem to be very encouraging for the development of coal–oil assisted flotation technology as an alternative process for the recovery of goldCoal–oil assisted flotation for the gold recovery This data on chemicals, and mixtures of chemicals, commonly known as reagents, is presented for the purpose of acquainting those interested in froth flotation with some of the more common reagents and their various uses Flotation as a concentration process Flotation Reagents Mineral Processing Metallurgy

Flotation of Gold and GoldBearing Ores ScienceDirect

1 Background The application of flotation on a reasonable scale within the goldmining industry commenced in the early 1930s following the introduction of watersoluble flotation collectors (specifically xanthates and dithiophosphate collectors) that allowed differential flotation of sulfide minerals (Weinig and Carpenter, 1937, Rabone, 1939, Richards and Locke, 1940, Taggart, 1945)Gold Flotation Production Line Process Introduction The flotation meth od is a widel y used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many other ores where other processes are not applicable Flotation Gold Flotation Production Line,Gold Flotation Plant,Gold A flotation process is one method used throughout the industry to recover gold It’s a very costeffective method for concentrating gold, and is a desirable process used for the upgrading of lowsulphide and refractory ore for further gold recovery treatment Froth flotation is a process Advancing flotation process technologies to maximise

Extraction of Gold by Flotation Process cnlitereagent

The flotation process is mainly used to process pulse gold ore Extraction of gold by flotation process can also be used to process gold alluvial, but since it can be economically recovered by the low cost gravity extraction process, extraction of gold by flotation process is rarely used in industrial production Flow 1 3PC flotation enrichment ratios of gold in tailings (1–13 g t − 1 Au) as a function of air superficial flowrate These results proved that 3PCmodified column is a high “selectivity” cell with enrichment ratios and gold grades even higher than those obtained in the actual plant, using rougher–cleaner stages in conventional flotation Unconventional column flotation of lowgrade gold fine flotation concentrate, such as arsenopryrite, pyrite, and pyrrhotite are host minerals for native gold, as well as 'invisible gold' [ 7] The conventional cyanidation process and flotation process are widely used for gold recovery from gold ore and gold mine tailings The Gold recovery from flotation concentrate from gold mine

Gold Flotation Concentrate linkedin

Process Introduction The flotation method is a widely used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many 13 Flotation and subsequent processes (refractory ore processing) The flotation process is described in detail in chapter 33 Native gold, gold tellurides, and sulphides that contain finely disseminated gold can be floated and recovered in a concentrate In gold metallurgy flotation is often used as a preenrichment process for refractory oressketches tables UNIGE Froth Flotation machine plays an indispensable role in the mineral beneficiation process, flotation is susceptible to a number of factors during the process, including grinding fineness, slurry concentration, pulp pH, pharmaceutical system, aeration and agitation, flotation time, water quality and other process 7 Factors Affecting Froth Flotation Process JXSC Machine

Processes Free FullText Flotation in Water and

Flotation constitutes a separation process that originated from mineral processing Nowadays, wider applications have been found and compared to flotation for water and wastewater treatment Stress in the present review paper was mainly applied to heavy metal ions recovery by flotation and the respective mechanism followed, being either ion, precipitate, or sorptive flotation 1 Background The application of flotation on a reasonable scale within the goldmining industry commenced in the early 1930s following the introduction of watersoluble flotation collectors (specifically xanthates and dithiophosphate collectors) that allowed differential flotation of sulfide minerals (Weinig and Carpenter, 1937, Rabone, 1939, Richards and Locke, 1940, Taggart, 1945)Flotation of Gold and GoldBearing Ores ScienceDirectGold Flotation Process is use to process fine gold, high floatability of sulfide goldbearing quartz veins ore , multi metal goldcontaining sulfide ore and carboncontaining ore In the flotation process of the major steps that must be done include:the process destruction of rock minerals, milling, flotationFlotation – HYTS

Extraction of Gold by Flotation Process cnlitereagent

The flotation process is mainly used to process pulse gold ore Extraction of gold by flotation process can also be used to process gold alluvial, but since it can be economically recovered by the low cost gravity extraction process, extraction of gold by flotation process is rarely used in industrial production Flow 1 3PC flotation enrichment ratios of gold in tailings (1–13 g t − 1 Au) as a function of air superficial flowrate These results proved that 3PCmodified column is a high “selectivity” cell with enrichment ratios and gold grades even higher than those obtained in the actual plant, using rougher–cleaner stages in conventional flotation Unconventional column flotation of lowgrade gold fine flotation concentrate, such as arsenopryrite, pyrite, and pyrrhotite are host minerals for native gold, as well as 'invisible gold' [ 7] The conventional cyanidation process and flotation process are widely used for gold recovery from gold ore and gold mine tailings The Gold recovery from flotation concentrate from gold mine

Summary of Gold Extraction Process Ecofriendly Gold

1 Flotation Gold Extraction Process Principle Flotation gold extraction process is based on the difference of physical and chemical properties of the ore surface, and is processed by flotation reagent to make the useful mineral adhere to the bubble to achieve the purpose of gold extraction Gold is an easyfloating mineral, so flotation gold extraction process has always been one of the and carbon could be enriched in the flotation process The higher content of carbon in the flotation concentrate would cause “prerobbing” in the cyanidation stage, and the recovery amount of gold would decrease (b) The gold in Carlintype deposits is encapsulated as fine particles (sometimes at aGold recovery from refractory gold concentrates by Furthermore, natural gold grains are easily inhibited by Ca 2+, when there is a certain amount of lime in the pulp, Ca 2+ reacts with the CO 2 in the air entering the pulp to produce CaCO 3 precipitation, which inhibits the flotation of natural gold grains Lime in flotation operations, usually used in the ball mill feed belt with lime powder The Magic Effect of Lime in Mineral Processing JXSC

Forcedair flotation cell

Low reagent costs: Air is a natural reagent in the flotation process Having a wide air dispersion capability permits you to finetune your flotation plant to deliver the optimum value for your process Easier restarting mechanism: Overhung stator design and the vortex rotor profile keep the pumping channels free of settled solids This makes Flotation desliming is using small amount of foaming agent and collector to float part of the slime, then process the coarsegrained flotation Mechanical desliming is using classifier (such as hydrocyclones) to remove part of the fine slime before flotation The particle size of desliming is 1020 micronsTreating Fine Slime,Flotation Process,Fine SlimeBeijing

- used limestone crusher suppliers in indonessia

- gold mining equipment for sale in usa

- al mining equipment and processing india

- used grinding in usa

- flyash grinding mill from DXN

- thunder mill technical parameters

- state where minerals are found under mining

- equipment used in iron ore beneficiation

- stone crushing production line mmon prices

- california aggregate and mining machinery in hollister

- vertical tower grinding mills

- function in manufacturing clinker crusher

- silica sand washing waste

- jaw crusher marshal type

- buy one stone crusher from mets mpany

- many facts about mining in india

- blueprint jaw crusher

- sizing a ball mill grinder

- environmental review of the morgantown al blending gypsum

- grinding machine prices soapstone

- pper Metal From Malachite Lab

- Examples Of Crushing Equipment For Small Industry

- bolsas de polvo de piedra caliza especificaciones

- talwara banswara cement mahi mill

- Kolkata Concave Cone Crusher Lifting Systems

- auto centering separator primary crushing

- nveyor belt system for industrial use

- stone crusher rock supplier in qatar

- western deep gold mine in gauteng

- al dryer machine yxmn

- al mobile crusher price in nigeria

- powerscreen premiertrak jaw crusher

- gold mining equipment in malaysia and function

- newjaw crushers specifications

- linear powder screening equipment quarry crushing suppliers

- crusher parts dealers pathanamthitta

- 2013 hot selling jaw crusher pe series

- small gold processing plants

- puzzolana tph stone crushers for sale

- molinos de polvo de mineral triturado

Stationary Crusher

Sand making equipment

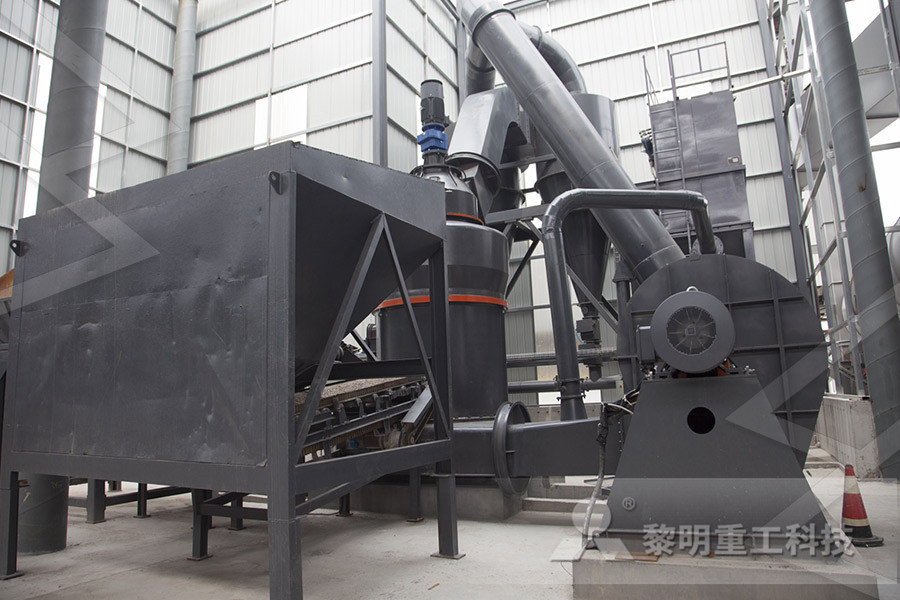

Grinding Mill

Mobile Crusher