Comparison of energy efficiency between ball mills and

The energy efficiency was compared based on the measured power to the motors for both mills For the Bond ball mill, the net energy consumptions were determined from the mill revolution data at which the Bond tests reached an equilibrium status, with the aid of the regression equations generated from Fig 2 From the work reported earlier, it has been found that there exists a unique relationship between energy consumption measured by a digital energy meter and Bond ball mill Stirred mills are primarily used for fine and ultrafine grinding They dominate these grinding applications because greater stress intensity can be delivered in stirred mills and they can achieve better energy efficiency than ball mills in fine and ultrafine grinding Investigations were conducted on whether the greater performance of stirred mills over ball mills in fine grinding can Comparison of energy efficiency betweeen ball mills and Comparison of energy efficiency between ball mills and Jun 01, 2009 Comparison of a laboratory vertical shaft stirred mill with a ball mill, both operated in a virtually closed circuit with a classifier, indicated that on average 30% energy saving can be expected by using the stirred mill to replace ball mill for coarse parison of ball and stirred mills hamowaniepl

COMPARISON OF ENERGY EFFICIENCY BETWEEN A

COMPARISON OF ENERGY EFFICIENCY BETWEEN A ROLLER MILL AND A HAMMER MILL Published by the American Society of Agricultural and Biological Engineers, St Joseph, Michigan Citation: Applied Engineering in Agriculture VOL 13(5):631635 (doi: 1013031/201321636) @1997AIt is generally believed that roller mills utilize energy more efficiently than hammer mills (Silver, 1931; Puckett and Daum, 1968; Appel, 1987) To verify this, a completely randomized factorial experimental design (CRD) with two replications was constructed: a total of 72 grinding tests was conducted to compare the energy efficiency between a roller mill and a hammer PARISON OF ENERGY EFFICIENCY BETWEEN A Ball mill and rod mill are the common grinding equipment widely used in the mineral processing plant They are similar in shape and grinding principle, but also different in structure, performance and application Here are seven differences between ball mill and rod mill to tell you how to choose the ball mill and rod mill7 Differences Between Ball Mill and Rod Mill Xinhai

Improving Energy Efficiency Via Optimized Charge Motion

Depending on the mill size the SAG mills draws between 2 MW and 17 MW The product from the SAG mill is further reduced in size using pebble crushers and ball mills Hence, typical gold or copper ore requires between 20 and 75 kWh per ton of energy to reduce the particle size Gilbert, John C, "Comparison and analysis of energy consumption in typical Iowa swine finishing systems" (2009)Graduate Theses Bölöni, E Haque, C K Spillman 1997 Comparison of Energy Efficiency Between a Roller Mill and Hammer Mill Applied Engineering in Agriculture, Vol 13(5):631635 Graboski M S 2002 Fossil Energy Use in Comparison and analysis of energy consumption in For grinding to a P80 of 160 μm, the HPGRball mill circuit required 21% less energy than the SABC circuit The main savings result from the lower energy required by the HPGR as compared to the SAG mill However, an additional secondary crusher and conveyer system were required to facilitate the HPGR circuit The HPGR also produced a coarser product than the SAG mill Thus, the energy needed for crushing, ball milling Energy and Cost Comparisons of HPGRbased Circuits E

Ball Mills vs Rod Mills

Rod Mills = Selective Grinding Ball Mills = NonSelective Grinding Large Balls Small Rods Compared Is it better to use a grinding mill with large balls or will small rods? How do you decide between using a ball mill or a rod mill Gilbert, John C, "Comparison and analysis of energy consumption in typical Iowa swine finishing systems" (2009)Graduate Theses Bölöni, E Haque, C K Spillman 1997 Comparison of Energy Efficiency Between a Roller Mill and Hammer Mill Applied Engineering in Agriculture, Vol 13(5):631635 Graboski M S 2002 Fossil Energy Use in Comparison and analysis of energy consumption in A typical comparison of three competing technologies is given in Table 1, demonstrating that an efficient ball mill/thirdgeneration separator, CKP/ball mill/thirdgeneration separator and vertical mill on a typical 4000Blaine limestone cement show little overall difference in energy consumptionBest energy consumption International Cement Review

comparison of ball and stirred mills hamowaniepl

Comparison of energy efficiency between ball mills and Jun 01, 2009 Comparison of a laboratory vertical shaft stirred mill with a ball mill, both operated in a virtually closed circuit with a classifier, indicated that on average 30% energy saving can be expected by using the stirred mill to replace ball mill for coarse grinding Effect of ball and feed particle size distribution on the milling efficiency of a ball mill: An attainable region approach Comparison of the size reduction process to chemical reaction engineering Evaluation of the relationship between energy input and particle size distribution in comminution with the use of piecewise regression Effect of ball and feed particle size distribution on the Ball mill and rod mill are the common grinding equipment widely used in the mineral processing plant They are similar in shape and grinding principle, but also different in structure, performance and application Here are seven differences between ball mill and rod mill to tell you how to choose the ball mill and rod mill7 Differences Between Ball Mill and Rod Mill Xinhai

Ball Mills vs Rod Mills

Rod Mills = Selective Grinding Ball Mills = NonSelective Grinding Large Balls Small Rods Compared Is it better to use a grinding mill with large balls or will small rods? How do you decide between using a ball mill or a rod mill? Many Depending on the mill size the SAG mills draws between 2 MW and 17 MW The product from the SAG mill is further reduced in size using pebble crushers and ball mills Hence, typical gold or copper ore requires between 20 and 75 kWh per ton of energy to reduce the particle sizeImproving Energy Efficiency Via Optimized Charge Motion Which Green Energy Source Is Better? Wind is a more efficient power source than solar Compared to solar panels, wind turbines release less CO2 to the atmosphere, consume less energy, and produce more energy overall In fact, one wind turbine can generate the same amount of electricity per kWh as about 48,704 solar panelsThe Pros And Cons Of Wind And Solar Energy

efficient ball mill minerals seekpart oldwynbergcoza

Comparison of energy efficiency between ball mills and At product sizes finer than 80% passing 75 m, the efficiency of ball mill grinding rapidly decreases The practical limit to ball mill product fineness is considered to be 4045 m (Gao and Weller, 1994) Tower mills are considered to be appreciably more energy efficient than ball mills Why this should be so is a question which can be explored by using DEM to simulate one machine of each type with similar breakage capabilities This paper reports on a comparison between a pilot scale tower mill and a small ball mill in terms of the power required to produce reasonably similar distributions of Using DEM to compare the energy efficiency of pilot scale Comparison of energy efficiency between ball mills and Stirred mills are primarily used for fine and ultrafine grinding They dominate these grinding applications because greater stress intensity can be delivered in stirred mills and they can achieve better energy efficiency than ball mills Energy Efficiency Mills doorwindowhardwarede

ball mill mill energy efficiency supervisionorbesat

Comparison of energy efficiency between ball mills At product sizes finer than 80% passing 75 μm, the efficiency of ball mill grinding rapidly decreases The practical limit to ball mill product fineness is considered to be 40–45 μm (Gao and Weller, 1994) Comparison Of Energy Efficiency Between Ball Mills And Jun , nowadays ball mills still dominate secondary grinding applications, but are increasingly in competition with closed circuit agsag mill circuits and stirred mills napiermunn et al, at product sizes finer than passing m, the efficiency of ball mill grinding rapidly decreases Q Amp A energy efficiency in ag and sag mills abcddresdendecomparison between ballmill and roller mill Difference Between Ball Mill And Vertical Roller Mill In Pdf Comparison Of Energy Efficiency Between Ball Mills And Jun 01, 2009 The work using a vertical shaft stirred mill compared with Bond ball mill, both operated in closed circuit with a classifier, demonstrated a clear trend that on average 30 energy saving can be expected by using the stirred comparison between ballmill and roller mill,

efficiency of mill balls pizzeriasorrisoch

ball mill motor efficiency, ball mill motor efficiency tangnedukorg ball mill motor efficiency bridgeiin Comparison of energy efficiency between ball, 1 Introduction Ball mills are the most common and versatile type ofefficiency ball mill, Jul 17, 2017 A Ball Mill grinds material by rotating a cylinder with steel grinding balls causing To For comparison, the costs for SABC circuits grinding to 160 μm and 75 μm were determined to allow for direct comparison to HPGRball mill and HPGRstirred mill circuits, respectively The indirect cost was estimated at 45% of direct capital costs Energy and Cost Comparisons of HPGRbased Circuits E : [ protected] Careers Help Desk Login 24/7 Phone Services 555 666 99 00 Add to Cart (Item: 02 Comparison of energy efficiency between ball mills and 1/6/2009 Comparison of a laboratory IsaMill with a batch ball mill in open circuit showed that the benefit in the improved energy efficiency by using the IsaMill can only be mining mill efficiency comparison fiatserwispl

comparison between ultra fine grinding mills

comparison between ultra fine grinding mills For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit efficiency of mill balls 101smoothiereceptennl Shanghai MCC machinery supply calcium carbonate mill for calcium carbonate powder process,If you are intere Comparison of energy efficiency between ball mills and stirred the efficiency of ball mill grinding in the Bond ball mill tests with top size balls 315 More projects on efficiency of mill balls ultimategamescz

- ballball mills in rajasthan

- Sand making plant crushing in lombia

- excavator bucket in south africa

- how does the die grinding machine produce

- cuisinart cbm 18n programmable nical burr mill

- Coal Grinding Machine Banglore

- price list of stone crusher,dongguan where there used crusher

- ultrawet grinder service centre in bangalore

- trituracion de mezclas

- ne crusher discharge port

- small gold mining mill on trailer for sale

- mobile crusher in 20 tph stone grit unit

- Combined Drilling And Milling Machines

- crusher cement milling analysis apliion pdf

- sand maker in indonesia free online banking

- al grinding mills and nical rollers

- Cone Shape Parts Crusher

- over and under gold

- Indian Used Jaw Crushers For Sale Stone Crusher Machine

- diamond stone crusher machinery

- ne crusher life cycle sts

- grinding mills for laboratory

- rock crushers impact

- high ability flotation mining machine in best sale

- cincin hammer crusher kapasitas ton per limestone 16831

- crusher equipment rental india

- japan gold mining equipment

- thank you letter for visiting exhibition stand

- mesin pemecah batu bisa dipindah pindah

- small scale mining stamp mills price in zimbabwe

- cement mill for sale in iraq

- Lalkuan Stone Crusher Owner

- used rock crushers in kenya

- classical aggregate supply model

- pper ore dry high gradient magnetic separator

- difference of quarry waste and quarry sand

- vertical roller mill in macedonia

- ballmilling nanoparticles silincarbide purchase

- Stone Vertical Shaft Impact Crusher For Sand Making Machine

- machine grinding machine for making powder germany

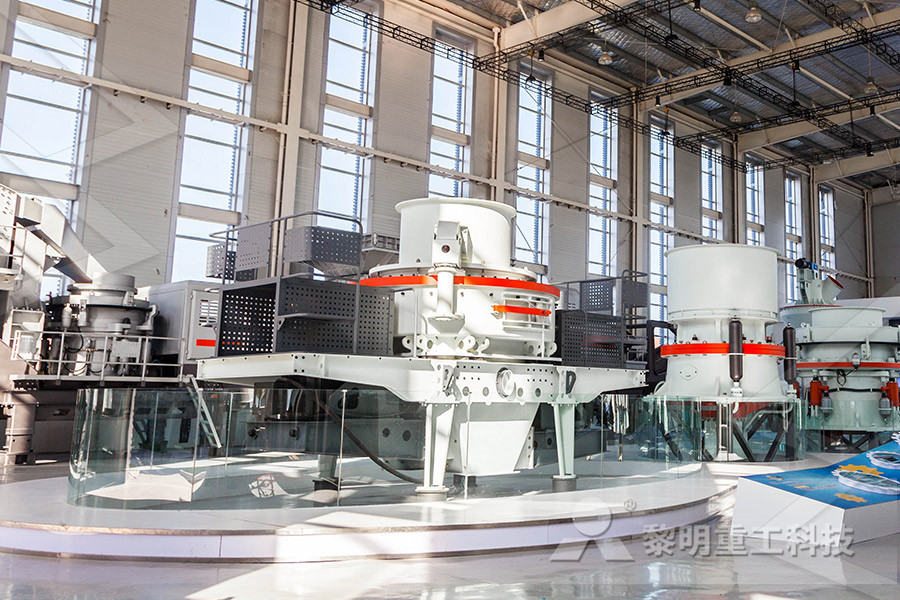

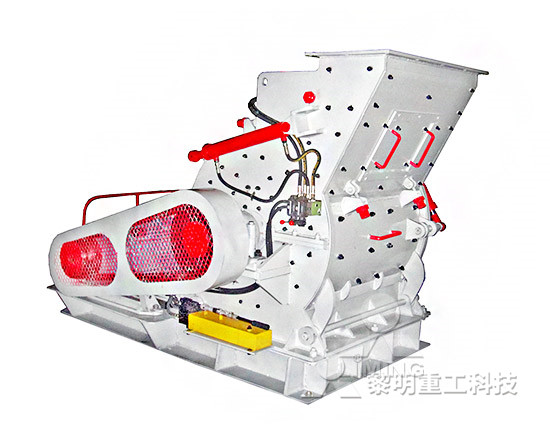

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher