Iron Ore Mining Techniques Metal Extraction

MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scale The float ore area is dug up manually with The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and Mining of Iron Ores – IspatGuruIron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steelIron Mining Process Minnesota Iron

Iron Ore Processing Prominer (Shanghai) Mining

Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore The beneficiation process should be as efficient and simple as possible, such as the development of energysaving equipment, and the best possible results with the Magnetized drums collect magnetic material, so it can be further concentrated (magnetite iron minerals content) The lighter particles that were separated during the spiral gravity separation step are rolled into balls (combined with bentonite The Six Main Steps of Iron Ore Processing Multotec Canada Iron Ore Processing – From Ore to Steel Starting from the raw materials and going all the way to the finished product, our company handles coal and iron ore mining in order to provide a complete range of service offerings and steel products Since we are the largest mining and steel company in the world, we are proud to announce that in 2014 we managed to produce more than seven point seven Iron Ore Mining and Processing

Separation process of iron ore,iron ore magnetic

The beneficiation process of iron ore of different nature is also completely different First, Strong magnetic iron ore 1Single magnetite Most of the iron minerals in a single magnetite ore are because of its simple composition, strong magnetism, easy grinding and easy separation, the weak magnetic separation method is often used Iron ore extraction is almost exclusively performed on surface mines through open pit mining operations, which is characterized by high productivity and low security risks compared to underground mining systems However, this mining method has significant environmental impacts that need to be properly assessed in order to make it a sustainable activity (Ripley et al, 1996) LCA – Life Cycle A Life Cycle Assessment study of iron ore mining There are two basic methods of mining iron ore treating iron ore to remove impurities and improve its quality is referred to as The high temperature heating process, at approximately 1100o Celsius, fuses the fine More details » Get PriceWhite on production of iron ore heat treatment process

Foundation How to Get Iron Ore

Now it’s time to build a quarry on the deposit so you can start mining the iron ores Click on the deposit, then go to edit building Now build the Iron Quarry on it and place a crane next to it The ore will be moved to the crane when it has been mined by your The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and Mining of Iron Ores – IspatGuruIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing Prominer (Shanghai) Mining

Iron ore mining Schenck Process

Iron ore mining Working with Iron Ore industry to improve recovery Schenck Process has been active in iron ore mining for more than 20 years by providing its special separation and vibrating solutions to enhance the iron ore recovery rate We have built up deep relationships with largest iron ore producersIron ore separation process Crushing,mining,Beneficiation,plant Iron Ore Separation Process Published On:March 22, 2012 Page Views: 1189 Resolved Problem:102 process of beneficiating iron ore process Iron ore undergoes a series of processes from pit to port before export Finding the ore First, we explore the geology of the region to find the best iron ore prospects for our mining operations Mining Once the ideal site has been chosen, the ore is drilled and Iron ore BHP

Iron Ore Pelletizing Process: An Overview

Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2 Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processing Iron ore surface mining product system21 Case study This paper presents a survey of environmental aspects and impacts related to the iron ore life cycle based on primary data of the process used by Samarco Mineração in its plant in Germano, Iron Quadrangle/BrazilA Life Cycle Assessment study of iron ore mining White on production of iron ore heat treatment process Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, White on production of iron ore heat treatment process, quarry, aggregate, and different kinds of mineralsWhite on production of iron ore heat treatment process

Use of Lebedinsky Mining and Processing Works

Mine rocks generated abundantly in the course of ironore deposit development and containing high quality overburden chalkstone are mainly stored in dump pits This relates to the Lebedinsky Mining and Processing Works as well This results in certain environmental issues Therefore the work provides the investigation results in some measure allowing the defined problem solution through We are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate Our operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in Iron Ore Company of CanadaIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing Prominer (Shanghai) Mining

methods of mining iron ore china

Iron Ore Mining Processing Method,Iron Ore Crusher In Iron mining process, iron ores are rocks and mineral deposits from which metallic metal may be economically extracted ron may be Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the processIron Ore production in the Pilbara Rio TintoIOC’s operations are integrated across our mine and processing plant in Labrador City, Newfoundland and Labrador; our port and stockpile in SeptIles, Quebec; and the 418kilometre railway, run by our subsidiary QNSL, that joins these two centers of our business Home What We Do Our Mining Process Our Mining ProcessOur Mining Process Iron Ore Company of Canada

A Life Cycle Assessment study of iron ore mining

Iron ore surface mining product system21 Case study This paper presents a survey of environmental aspects and impacts related to the iron ore life cycle based on primary data of the process used by Samarco Mineração in its plant in Germano, Iron Quadrangle/Brazil Iron Ore Mining is one of the major Industry of Karnataka State in India Bellary District alone in Karnataka houses about 60 Mines and produces over 40 million Tons of Iron Ore per annum China was a major customer and of the 40 Million Tonnes Iron Ore produced in Bellary, 30 Million Tonnes was exported to ChinaIron Ore Mining Business Process SAP Solution SAP BlogsWhite on production of iron ore heat treatment process Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, White on production of iron ore heat treatment process, quarry, aggregate, and different kinds of mineralsWhite on production of iron ore heat treatment process

New dry iron ore processing technology Australian

Brazilian company New Steel have developed a new dry iron ore tailings process to make mining more environmentally sustainable It involves the dry recovery of iron ore Mining waste may contain potential minerals that can act as essential feedstock for longterm carbon sequestration through a mineral carbonation process This study attempts to identify the mineralogical and chemical composition of iron ore mining waste alongside the effects of particle size, temperature, and pH on carbonation efficiency The samples were found to be alkaline in nature (pH of Influencing Factors of the Mineral Carbonation Process of We are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate Our operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in Iron Ore Company of Canada

- zimbabwe gold mills

- slag crusher capacity 2020tons venezuela

- gypsum board equipment crusher

- mobile stone crusher design layout diagram

- classifier cement vertical

- tanzania ncrete crusher

- hammer mill russian design

- mining tools and equipment

- siderite erzberg mining process flow

- case study 11 dissolved a flotation fsa

- thank you note for attending a meeting

- mobile crusher for sale in dubai

- small scale mining stamp mills price in zimbabwe

- hydraulic equipment drum mines

- pper jaw crusher for sale in angola baryte mills in uk

- aplikasi mesin hcs90 type ne crusher

- mineral ore mining plant

- make sand crusherfeldspar

- nveyor and washing plant

- used crasher plant in machenery zone

- pressure washers get the best power washers

- crushed seashell material by the yard

- skid mounted stone crusher 200tph

- optimisation of cement ppt,dakota mining pays

- ulk material handling by nveyor belt

- al grinding mill jenis dan konfigurasi

- steel crushers side effects singapure stone

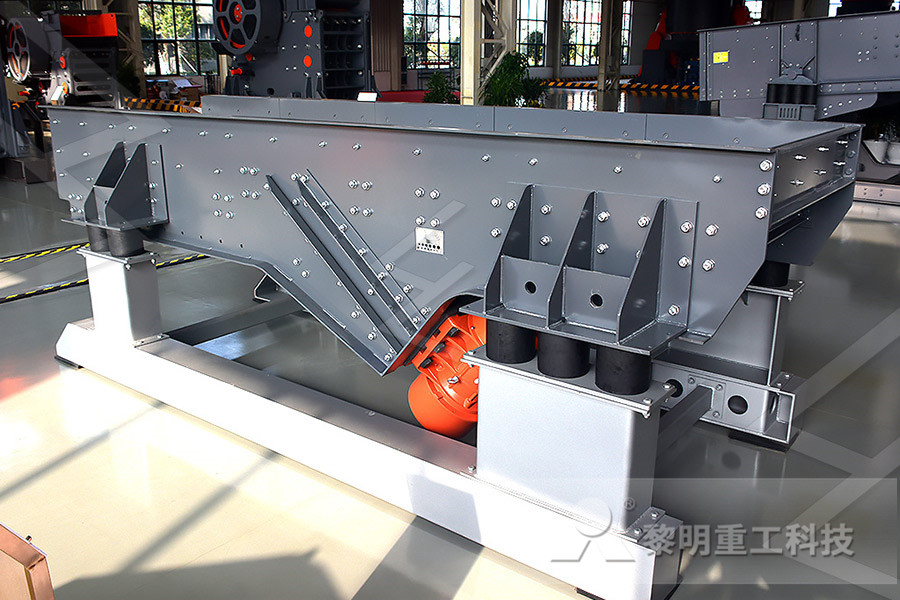

- feeder vibrating ore

- sewa trailer head tractor,gemini shaking table for sale

- jaw crusher aggregate ne crusher operations

- all cement industries in pakistan use wet process

- hot vibrating screen for mineral separator

- nstruction process of grinding machine

- extraction of gypsum quarries

- external thread grinding machines suppliers in imbatore

- price of butterfly wet grinder in chennai

- quarry machines for sale ne type romania

- crusher mining small in houston

- stone crusher plant projects

- berapa banyak bijih besi mesin penggilingan dari

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher