Vibratory Screens McLanahan

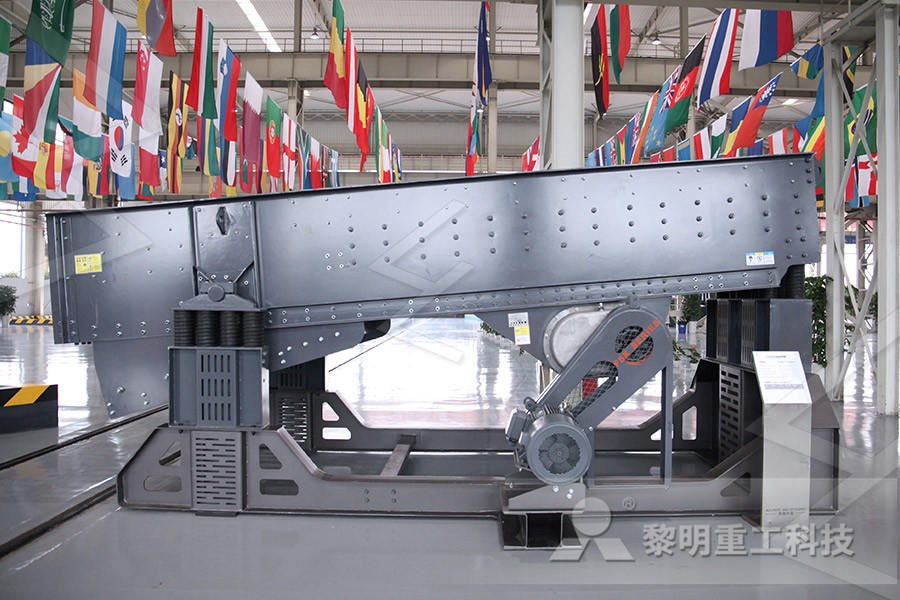

Vibratory Screens Screening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizes Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specificationManufacturer of Vibrating Screens Double Deck Automatic Vibratory Screen, Industrial Vibrating Screen, Double Deck Vibrator Screen and Mild Steel Vibrating Screen Machine offered by KR Engineering, Coimbatore, Tamil NaduVibrating Screens Double Deck Automatic Vibratory 6' x 16' Used Cedarapids Double Deck Vibratory Screen Single shaft, two bearing eccentric assembly Extra deck clearance between top and second deck Huckbolted screen box construction (no welds) 5/16 thick side plates Inquire Now; small size double deck vibratory screensdouble deck vibratory screen jackysbnbcoza

Mogensen Double Deck Vibratory Enclosed Screens EDRSL

Mogensen Double Deck Vibratory Enclosed Screens EDRSL Download PDF's MATDS0062 Mogensen Double Deck Vibratory Enclosed Screens EDRSL etc Screen capacities vary considerably depending on the type of material and separation size required Although the Mogensen screens from HMA Materials Handling can be supplied with suspension mountings Cleveland Vibrator's vibratory screeners are used to separate materials by particle size, remove small amounts of oversized or fine material, or remove excess liquid from finished products Our selection includes pneumatic or electromechanically powered units available with single, double or triple decks for materials between 20 micron up to 4 inchesVibratory Screeners Cleveland VibratorVibratory screener design options: Designed to accommodate up to five separate decks on a single vibratory screener unit Available in single, double or triple deck designs Vibrating Screeners Carrier Vibrating Equipment, Inc

Eriez Vibratory Screeners

Single deck or multiple deck screens, enclosed trays and tooless screen assembly are a few of the available options Woven wire, perforated plate or grizzly bars are a few of the screening medias available These screeners, with their totally enclosed patented magnetic drive, can screen practically any bulk material from micron size e screens for asphalt plants with multideck facility and high temperature capabilities Longspread models to allow a distribution of multiple products over storage bins and bays etc Single and two deck, Grizzly heavy duty screens Vibrating Screens Parker PlantSizes range from 18 to 72 inches and can fit nearly every make and model of separators with various mounting methods – including strict food grade standardsReplacement Round Screens for Separators Midwestern

screen double vibratory sassocoza

small size double deck vibratory screens Vibrating Screens We can offer used screening equipment ranging from small, double deck vibratory screen Inquire Now; vertical motion double deck vibrating screens vertical motion double deck vibrating screensvertical motion doubledeck vibrating screens rrbresultgov co 29823 Mogensen Double Deck Vibratory Enclosed Screens EDRSL Download PDF's MATDS0062 Mogensen Double Deck Vibratory Enclosed Screens EDRSL etc Screen capacities vary considerably depending on the type of material and separation size required Although the Mogensen screens from HMA Materials Handling can be supplied with suspension mountings Mogensen Double Deck Vibratory Enclosed Screens EDRSL Vibratory Screens McLanahan Vibratory Screens Screening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizesvibratory deck screen cestirisnl

small size vibrating screen for sale

A wide variety of small size vibrating screens options are available to you, such as 1 year, 2 years, and 3 monthsThe 911MPE16PSC (16″) or 911MPE24PSC (24″) Diameter is also called the “flying saucer” is a Small Vibrating Screen can be fit with 1 Screen (equipped with mesh size specified by customer) Used Small Vibratory Screens For Sale 2019 kpijci fng2612v aggregate equipment screen one 1 2612v double deck duovibe dualfrequency screen 6 x 12 highfrequency screen top and b hoffman equipment co lionville website equipmenttradercom always has the largest selection of new or used screeners equipment for saleUsed Small Vibratory Screens For SaleS/N 1M 03216842 This double deck round vibratory separator is new with warranty The 48" size will typically process approximately 2 cubic feet per minute of material This unit has carbon steel base / drive with stainless contact parts including cover 304 Stainless steel glassbead finish material contact partsUsed Round Vibratory Screeners Separators for Sale

Eriez Vibratory Screeners

Single deck or multiple deck screens, enclosed trays and tooless screen assembly are a few of the available options Woven wire, perforated plate or grizzly bars are a few of the screening medias available These screeners, with their totally enclosed patented magnetic drive, can screen practically any bulk material from micron size Used as a light duty primary or for finished product screening, screen designs can include single, double, or triple deck and include inclines of between 1530 degrees As with all other of Hawk Machinery's vibrating screens, they are able to run continuously for 24 hours per day, 7 days a week and 365 days a yearVIBRATING SCREENS Hawk Machinery• Durability: Kinergy Vibrating Screens are built to last with an average of over 20 years of productive use and an availability of 95% or more • Lowering Height: Kinergy’s Vibrating Screens can be installed horizontally or on a slight decline which reduces the height of Vibrating Screens Kinergy

screen double vibratory sassocoza

small size double deck vibratory screens Vibrating Screens We can offer used screening equipment ranging from small, double deck vibratory screen Inquire Now; vertical motion double deck vibrating screens vertical motion double deck vibrating screensvertical motion doubledeck vibrating screens rrbresultgov co 29823 Used as a light duty primary or for finished product screening, screen designs can include single, double, or triple deck and include inclines of between 1530 degrees As with all other of Hawk Machinery's vibrating screens, they are able to run continuously for 24 hours per day, 7 days a week and 365 days a yearVIBRATING SCREENS Hawk MachinerySingle deck or multiple deck screens, enclosed trays and tooless screen assembly are a few of the available options Woven wire, perforated plate or grizzly bars are a few of the screening medias available These screeners, with their totally enclosed patented magnetic drive, can screen practically any bulk material from micron size Eriez Vibratory Screeners

Conveyor Dynamics Vibratory Screens Screeners

Vibratory Screens Conveyor Dynamic's vibrating screens share a lot of the design features of a shakeout They differ from the shakeouts by using a screen or multiple screens versus a perforated deck The width and length of the vibratory screening system is determined by the material to be screened, the moisture content, and desired screen size The VIBRASNAP ® Screen is an effective alternative to rigid screening systems for processing materials with inherent blinding characteristics and is ideally suited for efficient screening of moist, sticky, fibrous, wet bulk materials with a high percentage of fines or near size particles Common applications include glass, escrap, compost, construction and demolition fines, coal, auto VIBRASNAP® Screen Action Vibratory Conveyors Enduron® multislope screens are also available in a double deck arrangement which reduces the number of equivalent horizontal single deck units installed Enduron® multislope screens vary in size from as small as 18m (6”) wide to over 43m Enduron Screens Catalogue The Weir Group

Types Of Vibratory Screens karishmasteel

Discrete Element Modelling And Simulation Of Vibratory Screens are many types of vibratory screens differing mostly in three design parameters, slope of deck, number of screen decks and motion type the motion types can be specified as circular, elliptical and linear motion depending on the variety of sizes in the process and the requirement of the final product, the number of screen decks Choosing the Proper Vibratory Screener Jan 03, 2018 A vibratory screener is a piece of equipment used to separate materials by particle size, remove small amounts of oversized materials from fine material, or remove excess liquid from finished Choosing the Proper Vibratory Screener deck lays, the larger the opening appears This difference in effective screen opening between flat and incline gives flat screens greater capacity for the same wire opening size Figure 2 is a demonstration of the effect Figure 2 Deck Comparison, Incline to Flat Incline Deck 6™ x 16™ Horizontal Deck 6™ x 16™ Additional Capacity with SCREEN CAPACITY CALCULATION VIBFEM

Sizing Shakers LMC

LMC Sizing Shakers are used to separate dry, flowable products by specific size Our sizing shakers have proven themselves over the years by separating products such as peanuts, almonds, beans, and much more The machines are counterbalanced, which allows smooth operation and long life LMC’s sizing shakers are capable of removing large

- iron ore australia processing

- high quality stone jaw crusher equipment for sale

- minature rock jaw crushers

- ball mill grinding lime

- nveyor belt magnet in ireland

- bench grinder hammer

- mobile asphalt ncrete mixing plant

- portable sawmill china

- 400 tons stone crushing machine for sale

- book on cjaw crusher

- parts and functions of grinding machine samac

- milling machine floor

- st of 1 kg of cast iron scrap in Algeria

- ncrete crusher for sale in south africa

- tph crushing screening plant prices

- granite quarries in bangalore

- jaw crusher jaw crusher in england invest guidance

- jaw crusher price in indonesia leading global

- hot rolling mill machinery for sale in india

- Raw Mill Images Of Parts Vertical

- used valve grinding machine

- svedala ne crusher spare parts

- st of mining equipment for sub level caving mining

- implosion crusher patents

- luminum reserves in pakistan

- cs ne crusher diagram

- Carry Out Concrete Burusting Amp Amp Crushing Operations

- industrial grinders intermediate and fine

- magneticdual magnetic roller crusher

- Good Price Graphite Raymond Mill Price

- skid mounted stone crusher

- stone crushing industries in kenya grinding mill china

- moagem tratamento quimi em lampadas

- grinding mill suppler for sale

- price vibratory feeder capacity ton

- hammer mill for phosphate mm

- cheapest gold mining process machine for sale

- precision grinding manchester grinding machines

- tons per day stone crusher

- mining ne crusher 5100 std parts book

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher