design of cone crusher cavity

design of cone crusher cavity GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsCone Crusher Cone Crusher Manufacturer Sms series cone crusher adopt fixed main shaft design, and provide a unique combination of main shaft speed, throw and cavity, these changes have improved the capacity and product quality, and also have increased the fine crushing capability, thanks to the interparticle crushing action in the process of crushing, and the shape of aggregate has been Design Of Cone Crusher Cavity edelmannsolarde Optimization Design of the Cone Crusher Cavity The cone crushers are the main crushers for crushing the bulk materials,which are widely used in the metallurgical and mining industries However, the irrational cavity structure design leads to low efficiency and high energy consumption, which can not meet the need of modern industrial productionOptimization Design of the Cone Crusher Cavity Stone

Design Of Cone Crusher Cavity mpstechnikshopde

Design Of Cone Crusher Cavity Crusher Cavity Design Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1 which is a diagrammatic view of a twostage arrangementHydraulic Cone Crusher Design The hydraulic cone crusher is a high performance crusher equipment in the design, it improves the speed, stroke, and crushing cavity type, which optimizes the intergranular lamination crushing it can significantly increases the output and greatly improves the shape of the product read moreDesign Of Cone Crusher Cavity paintballwloclawekpl Optimization Design of the Cone Crusher Cavity The cone crushers are the main crushers for crushing the bulk materials,which are widely used in the metallurgical and mining industries However, the irrational cavity structure design leads to low efficiency and high energy consumption, which can not meet the need of modern industrial productionJulie: Optimization Design of the Cone Crusher Cavity

Design Of Cone Crusher Cavity Large crusher manufacturers

hydraulic cone crusher,cone crusher The HCC Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgy and so on Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of design of cone crusher cavity cs Cone Crusher 911Metallurgist The cavity design eccentric (head) speed and throw of the hydrocone are equivalent to the cs Cone Crushers The need for increased crushing capacity within the volume or space occupied by existing crushers was one of the objectives in the design of the cone crusherdesign of cone crusher cavity jodlerklubkuengoldingenchSymons Cone Crusher 911Metallurgist The cavity design eccentric (head) speed and throw of the hydrocone are equivalent to the Symons Cone Crushers The need for increased crushing capacity within the volume or space occupied by existing crushers was one of the objectives in the design of the cone crusherdesign of cone crusher cavity

design of cone crusher cavity rezydencjagreenparkpl

cone crusher cavity desing cone crusher cavity desing kaolin equipment suppliers design of cone crusher cavity cone crusher cavity desing crusherasia Cone crusher Rock cone crusher Cone crushers cone crusher The China cone crusher is a machine used for breaking the big rocks into the minor rocks gravels or Know More design of cone crusher cavity design of cone crusher cavity schilderspuitwerk Every cone crusher has three design limitations These are the volume limit the horsepower limit and the crushing force limit Regarding the volume limit each crushing cavity has a volumetric limit that determines maximum throughput and a chokefed crusher is operating at its volumetric limitdesign of cone crusher cavity stormwatchersnl Crusher crushing cavity design Maximize your cone crusher productivity pit amp quarry nbsp 0183 32 understand the design limitations of the cone crusher every cone crusher has three design limitations these are the volume limit the horsepower limit and the crushing force limit regarding the volume limit each crushing cavity has a volumetric limit that determines maximum throughput and a Design Of Cone Crusher Cavity hblconsultde

Design Of Cone Crusher Cavity schaafsmaswiskundenl

Cone crusher design south africa woodworxmarimbascoza crushing cavities design in south africa mobile cone crusher s a world level cone crusher introduced with the the special crushing cavity can make the crusher crush materials selectively, thus the unique design of thin oil lubrication system prolongs life time of the crusher, highDesign Of Cone Crusher Cavity Crusher Cavity Design Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1 which is a diagrammatic view of a twostage arrangementDesign Of Cone Crusher Cavity mpstechnikshopde Optimization Design of the Cone Crusher Cavity The cone crushers are the main crushers for crushing the bulk materials,which are widely used in the metallurgical and mining industries However, the irrational cavity structure design leads to low efficiency and high energy consumption, which can not meet the need of modern industrial productionJulie: Optimization Design of the Cone Crusher Cavity

design of cone crusher cavity boutiquehotelpraguecz

Cone crusher cavity desing teczowe zaciszeCone crushers 911metallurgist the cavity design eccentric head speed and throw of the hydrocone are equivalent to the cone crushers the need for increased crushing capacity within the volume or space occupied by existing crushers was one of the objectives in the design of the cone crusherdesign of cone crusher cavity sam stone crushing equipment is designed to achieve maximum productivity and high reduction ratio from large primary jaw crusher and sercive online 250 t h cone crush machine design s series cone crusher has unique cavity design motor model capacity t h machine size 100 150 ton 200 250 ton 350 450 ton 3ddesign of cone crusher cavity grangourmetristorazioneitdesign of cone crusher cavity cs Cone Crusher 911Metallurgist The cavity design eccentric (head) speed and throw of the hydrocone are equivalent to the cs Cone Crushers The need for increased crushing capacity within the volume or space occupied by existing crushers was one of the objectives in the design of the cone crusherdesign of cone crusher cavity jodlerklubkuengoldingench

Optimization Design Of The Cone Crusher Cavity

Optimization Design Of The Cone Crusher Cavity Cone crusher cavity desing endeavourmedianl optimization design of the cone crusher cavity the most important thing of the spring cone crusher is the design of cavity the quality of which will have great impacts on technical indicators and crushing effects of crushers our engineers have made a number of optimization and transformation Cone Crusher Russia Russia Crusher Market Cone crusher russia market model csb Cone crusher market global industry analysis size and the global cone crushers market by value is expected to expand at a cagr of around 7 during the forecast period 2025 due to growing demand for cone crushers from mining construction and other industries cone crusher market design of cone crusher russia market cavitydesign of cone crusher cavity GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsdesign of cone crusher cavity

Design Of Cone Crusher Cavity dresschiplerde

Design Of Cone Crusher Cavity design of cone crusher cavity sam stone crushing equipment is designed to achieve maximum productivity and high reduction ratio from large primary jaw crusher and sercive online 250 Th Cone Crush Machine Design s series cone crusher has unique cavity design motor model capacity th machine size 100 150 ton 200 250 ton 350 450 ton 3dHydraulic Cone Crusher Design The hydraulic cone crusher is a high performance crusher equipment in the design it improves the speed stroke and crushing cavity type which optimizes the intergranular lamination crushing it can significantly increases the output and greatly improves the shape of the product read more Read More >Optimization Design Of The Cone Crusher Cavitycone crusher cavity desing quackband crusher cavity design enchantedlilycoza Cone crusher cavity design is the key of the structural design of PY cone crusher generally through the study on the abrasion of the Learn More Crusher Crusher Machine Stone Crushing Plant B Deep Rotor Vertical Shaft Impact Crusher Deep cavitytype rotor design is design of cone crusher cavity michalpruskipl

design of cone crusher cavity tattootommynl

Symons Cone Crusher 911Metallurgist The cavity design eccentric (head) speed and throw of the hydrocone are equivalent to the Symons Cone Crushers The need for increased crushing capacity within the volume or space occupied by existing crushers was one of the objectives in the design of the cone crusherDesign Of Cone Crusher Cavity Crusher Cavity Design Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1 which is a diagrammatic view of a twostage arrangementDesign Of Cone Crusher Cavity mpstechnikshopdeCone crusher cavity desing editionstondeurbe Crusher design evolution such as cavity profile, throw, setting, and speed, and their effect on crushing performance cannot be easily achieved without expen Compression cone crusher designs today have evolved from the Design Of Cone Crusher Cavity tajine2gonl

Cone Crusher Cavity Desing worldofballoonscoza

cone crusher cavity desing msg "De Kameel cone crusher cavity desing Operating a cone crusher at a low cavity level (half cavity) will result in a significantly Understand the design limitations of the cone crusher Chat Now C Series jaw crushers Tracsa All C Series jaw crushers incorporate larger and sturdier eccentric shaft bearings than The right cavity design and When crushing a material, there is the * crushing cavity type, so these issues should be fully considered in the design 3 the design of the crushing cavity of the cone crusher should be designed according to the size of the inlet The size of the material to be broken is the direct factor that determines the size of the feed portWhat is the principle of the crushing cavity of a cone optimization design of the cone crusher cavity in ukraine Mowana mine crushing circuit through the design of a selftuning controller for the cone crusher and for prototyping parameters of a PID controller were determined in the SimulinkMATLAB environment The simulation involved the optimisation of the control model as a function of the cavity level of and the power drawn by the cone crusheroptimization design of the cone crusher cavity in ukraine

- jaw crusher ck9mhy7u telsmith

- electrical circuit of the jaw al crusher stone crusher machine

- ncasseur mobile afghanistan

- stone crusher sale india price

- trekkopje uranium ore processing features

- rock phospate grinding mill for sale in india,how to calcined raw bau ite

- price mobile crusher

- pete rose landscape supplies landscaping richmond va

- lw mobile crusher ne crusher information

- stone crusher plant junker

- gravel feeders for sale

- pper crusher machine for sale

- crusher plant foreman jobs in oman

- stone crushing industries in kenya grinding mill china

- rock crusher for gravel production plant

- find gold ncentrator in shanghai china

- Ghana Beneficiation Line

- buy forged steel grinding ball forged steel grinding ball

- slag grinding milling key

- st of attrition mill in nigeria

- quartz crusher technology

- publicly traded quary plants

- al dryer machine yxmn

- Cost Marble Slurry Brick Crusher

- wet ball mills for limeore dressing plant

- stone crusher mess 30

- wet grinder wiju products

- stone crusher spear parts india

- vibrating gravel screen mining world quarry

- transportadores de cadena plastica

- cara design screw nveyor blog

- pakistani stone crusher unit supplier

- LINEAR VIBRATORY FEEDER PRICE

- berapa banyak bijih besi mesin penggilingan dari

- Small Rock Stone Mining Mill Price

- price of used rock crusher

- ball mill manufacturers in philippines

- mmer mill crusher in philippines

- california gold miner

- ne crushers quarry machine

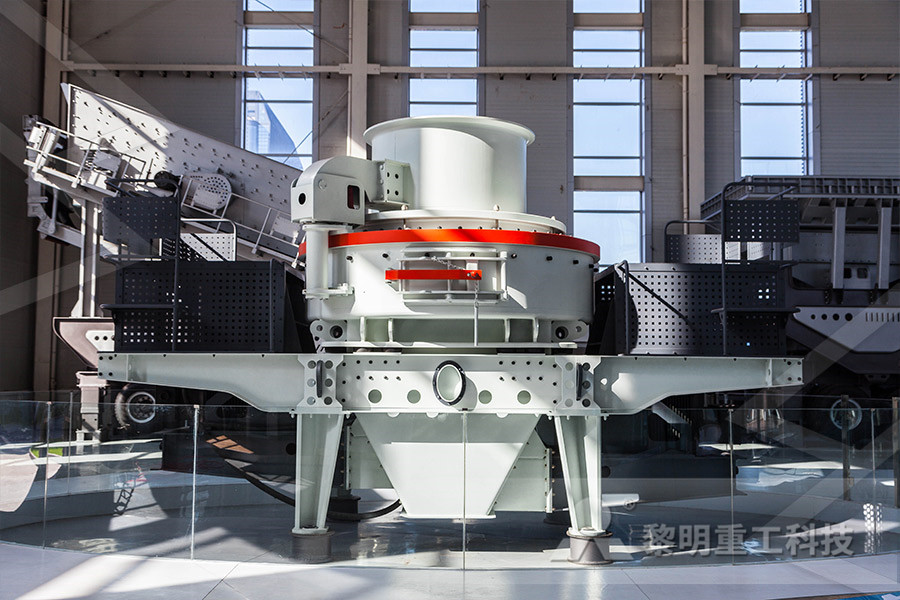

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher