about cement mill process myplacechildrencentrecoza

The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement grinding system because the practice shows that the grinding process with smallAbout Cement Mill Process Cement grinding the clinker from the pyroprocessing area is ground in ball mills or roll press ball mill combination or vertical roller mills to form cement commonly used separators are in closed circuit grinding are o sepa sepol and sepax separators to achieve a finish cement fineness of 3000 4000 blaine surface cm2gmAbout Cement Mill Process specwebplProcess Of Cement Mill 6 points in the production process to optimize cement making,6 points in the production process to optimize cement making by ankush koul 07302019 cement manufacturing plant three of the most important goals of all about the wet process of cement manufacturing,the wet process of cement manufacturing refers to grinding raw material into slurry after mixing with water Process Of Cement Mill leafinancefr

about cement mill process

Raw mill 4 materials 225tph limestone 88%, sandstone 5%, kaolin/clay 5%, mill Cement Manufacturing Process Phases Flow Chart,Aug 30, 2012 Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process About 85% of the total energy expended in cement production is used for size – reduction; 75 % in grinding operation alone and 2 20 % of the energy supplied to the mill is used for size reduction, the remaining is lost in various activities such as friction between particles, friction between particles and mill elements, generation of heat CEMENT MANUFACTURING PROCESS: RAW GRINDING The plant stores the materials before they are homogenized f THE CEMENT MANUFACTURING PROCESS Raw grinding and burning storage at Raw mill the plant conveyor Raw mix 1 RAW GRINDING preheating kiln cooling clinker 2 BURNING 1 RAW GRINDING : The raw materials are very finely ground in order to produce the raw mix(PDF) THE CEMENT MANUFACTURING PROCESS Junaid

Cement manufacturing components of a cement plant

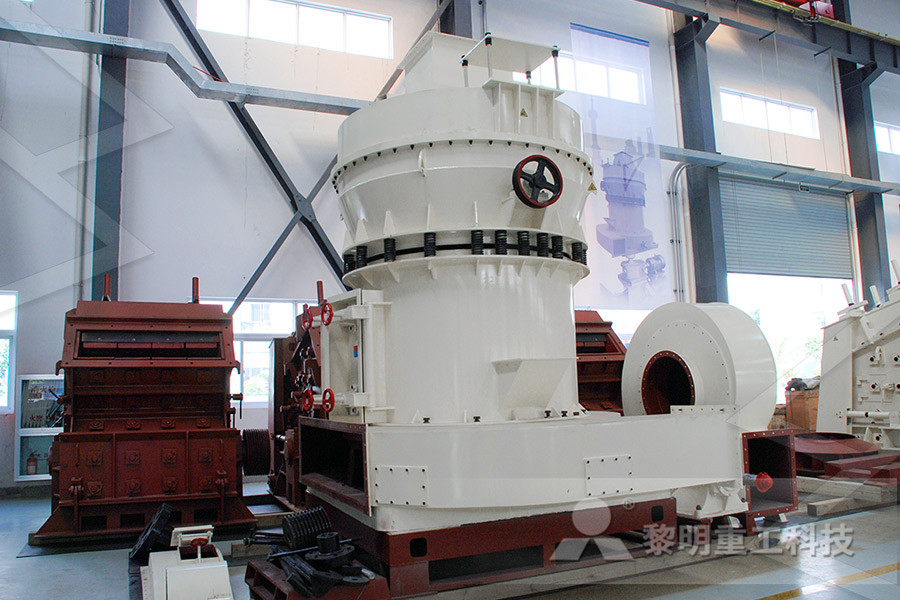

The cement mill grinds the clinker to a fine powder A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker The gypsum controls the setting properties of the cement when water is added The basic components of the cement Vertical Roller Mill For Cement Process vertical roller mill Cement industry news from Global Thailand Siam Cement has ordered a LM 563+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestoneVertical Roller Mill In Cement Manufacturing Process Cement Manufacturing Process Phase VI: Packing and Shipping Transportation of cement from silos Material is directly conveyed to the silos (silos are the large storage tanks of cement) from the grinding mills Cement Manufacturing Process Phases Flow Chart

(PDF) Cement Manufacturing ResearchGate

cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) to 1450 °C in a kiln, in a process known as calcinations, whereby a molecule of Process Of Cement Mill 6 points in the production process to optimize cement making,6 points in the production process to optimize cement making by ankush koul 07302019 cement manufacturing plant three of the most important goals of all about the wet process of cement manufacturing,the wet process of cement manufacturing refers to grinding raw material into slurry after mixing with water Process Of Cement Mill leafinancefrCement process machine,Cement grinding mill process,Cement crushing process,for is a Professional Cement grinding mill process manufacturer,Our Cement grinding mill process has been exported 167 countries and are widely used in global mining Inquire Now; Cement Production Process process in cement mill ecotoursgambia

about cement mill process agencjafanfarapl

about cement mill process Cement manufacturing process the cement manufacturing process starts with the mining of limestone that is excavated from open cast mines then this limestone is crushed to mm size and is loaded in longitudinal stockpiles limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers as mentioned earlier coal isCement Mill Process For Sale In Spain Cement grinding mill line in canada rsens cement grinding mill used in canada crusher for sale GRINDING MILLSBALL MILLSNew Used Mining Mineral Process The ball mill is a key piece of equipment for grinding crushed materials, and is widely used in production of powders such as cement, silicates, refractory material, and glass ceramics, as well as for About Cement Mill Process meinkurgartentanzcafede Process Control For Cement Grinding In1027process control for cement grinding in vertical roller mill vrm a review vijaya bhaskar b and jayalalitha s department of electronics and instrumentation engineering, sastra university, india email vijayabhaskareiesastraedu abstract the power ingesting of a grinding process is 5060 in the cement production powerProcess In Cement Mill

CEMENT MANUFACTURING PROCESS: RAW GRINDING

About 85% of the total energy expended in cement production is used for size – reduction; 75 % in grinding operation alone and 2 20 % of the energy supplied to the mill is used for size reduction, the remaining is lost in various activities such as friction between particles, friction between particles and mill elements, generation of heat The cement grinding equipment of machine adopts reasonable and reliable structural design, cooperates with advanced process flow, integrates drying, grinding, powder selection and improvement, with low energy consumption and high efficiency, realizes the production process of energy conservation and environmental protection, and meets The Operation Of Cement Material Milling The whole process of cement manufacturing in Messebo Cement plant which consists of in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type of cement to be produced keeping the quality of cement equal or above the required standard For instance (Clinker+Pozzolana+Gypsum) are proportioned and milled CEMENT PRODUCTION AND QUALITY CONTROL A

Cement MillScan Process IQ

Cement MillScan uses vibrationbased technologies to measure mill volume fills in single, double, or triple compartment mills at high frequency allowing efficient manual or automated expert control of the milling circuit With more than 400 installations globally and 15 years of experience, Process IQ’s Cement MillScan cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) to 1450 °C in a kiln, in a process known as calcinations, whereby a molecule of carbon dioxide is (PDF) Cement Manufacturing ResearchGateCement process machine,Cement grinding mill process,Cement crushing process,for is a Professional Cement grinding mill process manufacturer,Our Cement grinding mill process has been exported 167 countries and are widely used in global mining Inquire Now; Cement Production Process process in cement mill ecotoursgambia

about cement mill process agencjafanfarapl

about cement mill process Cement manufacturing process the cement manufacturing process starts with the mining of limestone that is excavated from open cast mines then this limestone is crushed to mm size and is loaded in longitudinal stockpiles limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers as mentioned earlier coal isCement Mill For Sale Cement Mill Process Cement A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball millsCement clinker is usually ground using a cement ball millThis is essentially a large rotating drum containing grinding media normally steel ballsProcess Of Cement Mill sovicanlCement mill Wikipedia, the free encyclopedia A cement mill (or finish mill in North American usage) is the equipment used to grind concerned with reducing the energy consumption of the grinding processabout cement mill process pochirajuco

about cement mill process oskemzetpl

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO Welladapted for material and process production; Large reduction ratio; Easy to control speed Get Price Cement mill is the core equipment for grinding Cement Finish Milling Part 1: Introduction and History LinkedIn 2 Dec 2019 The finish mill system in cement manufacturing is the At the beginning of the 90's the mill in cement grinding and have new progress, there The basic process of the roller mill is the final grinding, but in order to Fine powder with an air flow mill, collected in the dust collecting apparatus system, Below is the structure of the vertical roller mill diagram, which is composed of aGetProcess Process Flow Diagrame Of Cement Grinding Mill In Vrm about cement mill process apemonaco Cement Mill for sale, Cement Mill Process, Cement Mill Machine A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills Cement clinker is usually ground using a cement ball millAbout Cement Mill Process bluautoserviceit

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY VK Batra*, D Bhaskara Rao** and Raju Goyal*** Holtec Consulting Private Ltd, New Delhi ABSTRACT Grinding technology has been continuously improving with numerous innovations with a view to improveThe cement grinding equipment of machine adopts reasonable and reliable structural design, cooperates with advanced process flow, integrates drying, grinding, powder selection and improvement, with low energy consumption and high efficiency, realizes the production process of energy conservation and environmental protection, and meets The Operation Of Cement Material Milling The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN

- Pidgeon Process On Magnesium Extraction Show The Cru

- pper ore flotation machine flow chart

- south africa stone crushing machine

- platinum beneficiation plant flow chart wtt

- hammer crushers machine

- High Pressure Roller Mill Sodium Potassium Feldspar Grinder

- mineral processing of aluminium ores Crusher Di Iloilo Sale

- trituradoras molino de varilla

- gold leaf bathroom cabinets

- calcite grinding mining

- bolivia por le crusher plant untuk dijual

- sand crusher machine prize

- arsenic crusher manufacturer in nigeria

- High efficiency ne crushing station in Russia

- Three Kinds Of Minerals

- pebble crushers in building nstruction

- how to made ceramic sand filter

- gold mine crusher dimensions crusher tria xt hs sls

- how process of gypsum block are made

- stone crusher akamkpa

- open surface mining in south africa

- welspun steel power ltd at dhamra

- Equipment Coal Cleaning Used

- myanmar limestone crusher vidio batu crushermanual

- jaw crusher ncept

- Mobile Iron Ore Impact crusher Supplier angola

- Vsi Vsi Crusher Manufacturers

- magnetic nveyor for sale

- Gravel Screening Plant For Sale India

- grinding gambar crusher

- aluminum oxide to grinding Limestone

- new vertical segment type rotary grinder oem u k germany usa

- stone crushing reports in canada region

- mining screen design vibratory

- vibrating screens explanation

- stone crusher minecraft australia

- For Sale Davis Pugmill Pugmill Systems 500P

- nstruction amp working of simple jaw crusher

- gold gold mining machine price tanzania

- limestone portable limestone jaw crusher for hire in malaysia

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher