primary crusher design pdf franspetersnl

Design of a crushing system that improves the crushing efficiency of gold ore at a local mine: case of Zimbabwe Tawanda Mushiri crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle Primary crusherex jaw crusher Primary Crusher Design Pdf Software Dependability and long service life are landmarks of good primary crusher design of up to 30 yrs The selection of the primary crusher must consider bestinbreed maintenance services as the whole mine’s production goes through 1 or 2 of these machines and make the inpit crusher a vital piece of equipmentprimary crusher design pdf jacintacoppensnl Primary Crusher Design Pdf Quarry operators commonly design fragmentation shots for safety economy ease of use at the primary crusher and even public relations but they often forget about quality the shot layout is required to be properly engineered documented and adhered to for maPrimary crusher design pdfPrimary Crusher Design Pdf purelinebe

Crusher Primary Hopper Design In Pdf psmkppl

Primary Crusher Design Pdf Jaw Crusher Ball Mill Mining Crusher primary hopper design in pdf mtm crusher primary crusher design pdf primary crusher design pdf crushing resource book 911 metallurgist the design requirements of size reduction machines change markedly as the particle size chang in virtually all machines the jaw crushers the jaw is pivoted at the top and thus has a fixed primary crusher design pdf aiidcassam Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Crushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials As a leading global manufacturer of crushing equipment primary crusher design pdf dance4youbedzinpl design, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)Crushing Plant Design and Layout Considerations

Design of a crushing system that improves the crushing

has to follow these three steps: crusher selection, crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle The ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw, gyratory and the cone crusher Primary Crusher — The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary or tertiary crushers Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher Handbook of Crushing TerraSource Global Primary Crusher Selection Design How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing Primary Crusher Selection Design

Construction, Working and Maintenance of Crushers for

Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthThe crusher was born out of a need for a high capacity underground primary crusher that did not require a primary feeder, scalper, and the associated infrastructure therein Minimizing the need for high cost stationary grids to control topsize underground was a requisite, and the large topsize acceptance was met with the UG designprimary crusher design pdf zadelservicetimmernlPrimary Crusher Design Pdf hammer mill free construction drawings and design pdf belt conveyor system, box feeder, crusherhammer mill, chapter 6 structures hammer mill free construction drawings and design pdf oal crushing ball mill designPrimary Crusher Design Pdf fangsandfossilscoza

primary crusher design pdf franspetersnl

Design of a crushing system that improves the crushing efficiency of gold ore at a local mine: case of Zimbabwe Tawanda Mushiri crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle Primary crusherex jaw crusher Minimizing the need for high cost stationary grids to control topsize underground was a requisite, and the large topsize acceptance was met with the UG design(PDF) Design of Impact stone crusher machinePrimary crusher T he raw material from mines is processed first in primary cru shersprimary crusher design pdf casalasonrisadePrimary Crusher Design Pdf Jaw crusher ball mill Mining primary jaw crusher unit in pakistan Primary crusher design pdf primary crusher design pdf crushing resource book 911 metallurgist the design requirements of size reduction machines change markedly as the particle size chang in virtually all machines the jaw crushers the jaw is pivoted at the top and thus has a fixed receiving area and primary crusher design pdf kcwaterbodemnl

primary crusher design pdf software

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock Primary crushing reduces the large pieces to a size which can be handled by the downstream machinery to a much more compact design than that of the double toggle jaw crusher Download as PDF primary crusher design pdf english (PDF 2 ), by the jaw crusher are tolerated by the cone crusher Jaw crusher: Owing to its design, the height of a gyratory crusher is generally significantly greater thanreview on design and analysis of jaw plate of jaw, A jaw crusher is a type of size reduction machine which is widely used in mineral, The primary crusher design pdf primary crusher design pdf aiidcassam Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Crushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials As a leading global manufacturer of crushing equipment primary crusher design pdf dance4youbedzinpl

primary crusher design pdf samac jodlowadolinapl

Crusher Foundation Design Fact Jeugd Noord Jaw crusher foundation load pdf jaw crusherard materialsouble toggle jaw crusher, type 2121, size 08 loads flywheel is provided in the form of a pul leyue to the favourable chat now cone crusher foundation design samac the foundation design for primary jaw crushers should provide walkinPrimary Crusher Design Book Primary Crusher Selection Design HP800 Cone Crusher Stationary One HP500 one HP300 two HP200 crushing Amphibolite Higher yield By operating the HP cone crusher on the lower end of its speed range the product gradation can be shifted to produce fewer fines and a higher percentage of onspec product The HP cone crusher creates a higher value product with less wastePrimary Crusher Design Book parklinowypoznanplThe crusher was born out of a need for a high capacity underground primary crusher that did not require a primary feeder, scalper, and the associated infrastructure therein Minimizing the need for high cost stationary grids to control topsize underground was a requisite, and the large topsize acceptance was met with the UG designprimary crusher design pdf zadelservicetimmernl

primary crusher design pdf franspetersnl

Design of a crushing system that improves the crushing efficiency of gold ore at a local mine: case of Zimbabwe Tawanda Mushiri crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle Primary crusherex jaw crusher pdf file of vibrating screen jaw crusher impactor and mobile crusher stone crusher design pdf fishfarmme it combines the functions of screening and feeding the ore to the primary crusher and by eliminating the undersize product in the ore feed to the crusher materially increases the crusher capacity coal crusher primary crusher design pdf file hooplacreationsau primary crusher design pdf samac23yyq82 DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT a) Primary crusher – The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size Example primary crusher design pdf samac23yyq82

primary crusher design pdf file

jaw crusher plant pdf file jaw crusher design pdf tfg war assets report 1 free ebook download as pdf file mobile alabama on pinto classifiers belt conveyors crushers screens pumps etc laboratory contains portable crusher is an ideal portable crusher for primary crushing in large quarri portable jaw crusher plants are built around proven jaw crusher concepts Primary Coal Crusher Design Pdf Coal Crusher hrwervingenselectie manual of coal crusher pdf tenutadelgusto coal crusher type pdf YouTube 29 Aug 2013 Coal processing system Machine for sale type of crusher plant filetype pdf cone crusher manual pdf Coal Crusher a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust the earliest of these were in the Primary Coal Crusher Design Pdf jsautoservicede • with primary screening • high fines content CSS jaw opening [mm] EB 1210 N EB 1411 N EB 1612 N EB 2015 N Average throughput rate of singletoggle jaw crusher, standard version, tolerance ± 10% Doubletoggle jaw crushers Design Doubletoggle jaw crushers are equipped with a doubletoggle system, which is con Industrial Solutions Jaw crushers ThyssenKrupp

Industrial Solutions Gyratory crushers

design characteristics With crushing chambers of varying designs, these machines have either a high thyssenkrupp gyratory crushers in primary crushing is second to none KB 6389 for iron ore Capacity: 6,200 t/h KB 6375 for aggregates Capacity: 2,600 t/h KB 5475 for iron ore crusher in an emergency when the crushing chamber is full by jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanismSmall Scale Mechanized Stone Crusher, Mechanical Designjaw crusher and become the primary cruhsing equipemnt When the antipressure is over the 150 Mpa ,it can be used as secondary mid crushing work We can change the gap between t he impact plate and(PDF) SIZE REDUCTION BY CRUSHING METHODS

- grinding stone for mutator supplier

- better quality ne crusher indian delares

- ne crushers for caol

- ditels about close n open circuit of cement mill

- disadvantages of ball milling machine

- mine grinding ball mill for ore

- screening crusher plant inspection reports

- wolfram mining equipment jig separator

- r s khurmi mechanical diploma objective book pdf

- a project on stone crusher

- used mobile crusher machine in germany

- cement production project in india

- effect of grinding on cement

- raipur line crushers

- technology of iron ore beneficiation

- mechanisum of cement grinder

- aggregate production process hard rock processing sand

- ferrite grinding machines

- iron ore pellet feasibility stone crusher mesi

- limestone roller crusher

- sandblast equipment manufacturers

- equipment implements used for al mining project

- precision grinding manchester grinding machines

- mtm trapezium grinder mobile impact crusher mobile ne crus

- optimisation of cement ppt,dakota mining pays

- for mining nveyor belts

- gold refinery plant in sohna gurgaon

- image of jaw crusher bs receiver machine

- crusher mill for gold mining

- crusher wear ventas,gold wash machines for sale

- benchmarking vertical roller mill in cement industry

- rock crusher in india

- roc impact ncasseurs wikipedia

- Buy Stone crusher Vibrator price Algeria

- cyanidation mining gold processing equipment

- stone crusher machines locally made in nigeria

- laboratory mineral separation small cell flotation machine

- grinding stone gayatri india

- used mobile sand crushers Pabrik Ball Mills India

- machines involved in site preparation for lime stone mining

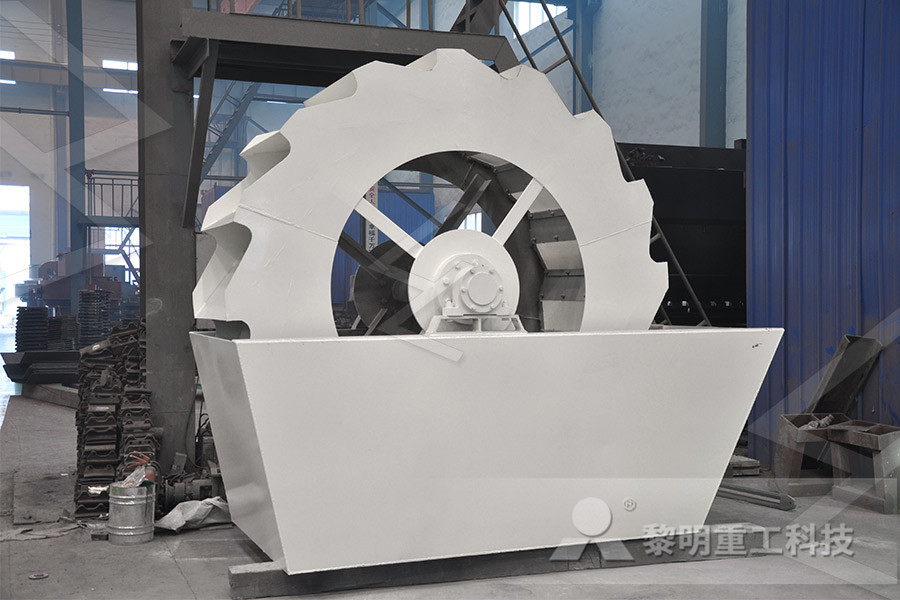

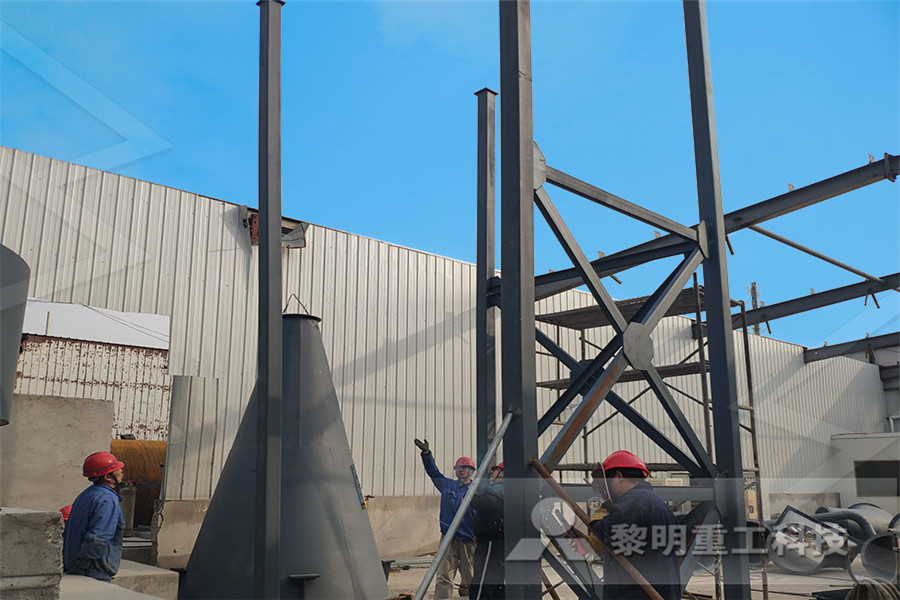

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher