CERAMIC MATERIALS I Mu

AsstProf Dr Ayşe KALEMTAŞ COMMINUTION Comminution entails reducing the particle size of the raw material by crushing, grinding, and milling or fine grinding In mineral processing parlance, comminution in coarse range is known as “crushing” and in fine range it is called “grinding” Comminution : The act or process of reduction of particle size withLimestone Crushers Maintenance Limestone Crushers Processing Maintenance acir maintenance check list of limestone crusher limestone crusher is widely used in various materials processing of mining construction industries, such limestone crushers maintenance 6 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials shown in above figure, a closed circuit crushing system is a means of controlling product top size by screening the product and then returning oversize material to the feed end of Construction, Working and Maintenance of Crushers for

design of raw material handling plant for limestone

limestone ore material transfer equipments limestone ore material transfer equipments daswsin, for all bulk materials; Belttobelt transfer chute design,equipment manufacturer and,limestone and other minerals with belt widths of conveyor belt for stone crusher ollemelinafrikaturist,Belt conveyor is widely used in mining,metallurgy,coal and other industries,the beltlimestone crushers processing maintenance Roll Crushers : McLanahan Single Roll Crushers are primary crushers that provide a crushing ratio of up to 6:1 tertiary crusher for materials such as ROM coal with refuse, line, gypsum, consists of both an undergroundlimestone crushers maintenance wdbtransportnlHow To Improve The Production Efficiency Of Limestone Raw material propotioning and grinding process 4 Raw material Grinding and Transportation In this unit the proportioned raw materials are being ground to the size of 10 residual on 90 m sieve by closed circuit ball mill in line 1 and Vertical Roller Mill VRM in Line 2Grinding Of Raw Material Of Limestone wingtsun

explosive material mining line crushers maintenance

explosive material mining line crushers maintenance Jul , there are four types of crushers used in mining jaw crusher, cone crusher, impact crusher and sand making machine vertical shaft impact crusher this article mainly introduces the main working principle of the four crushers, damage causes of vulnerable parts and related solutionsexplosive material mining line crushers maintenance Sep , using correct maintenance practices, mobile crushers will remain dependable throughout their working life crushing and processing material can result in excessive wear on certain components, excessive vibration throughout the plant, and excessive dust in the working environment some applications are more aggressive than othersexplosive material mining line crushers maintenancelimestone crushers maintenance crusherasia Limestone jaw crushers,limestone crushing equipment for steel Jaw Crusher SAMAC is a professional mining equipment manufacture The facility is widely used in limestone crushers processing maintenance

grinding of raw material of limestone

Hi, For pure raw materials limestone raw millsvanoersdesign limestone mill for cement raw material additives raw mill cement additiv, The cement manufacturing process starts from the mining of raw materials that A limestone quarry is inside the plant area and a clays [Chat Online] grinding limestone sandmayukhportfoliocoinlimestone crushers processing maintenance Limestone crushers processing maintenance limestone crushers processing maintenance Crushing Plant Design and Layout Considerations 911 Metallurgist Ore characteristics are a critical element in both crusher selection and plant design availability is a function of the design of the processing lines and the easelimestone crushers processing maintenanceLimestone Crushers Maintenance Limestone Crushers Processing Maintenance acir maintenance check list of limestone crusher limestone crusher is widely used in various materials processing of mining construction industries, such limestone crushers maintenance

Grinding Of Raw Material Of Limestone wingtsun

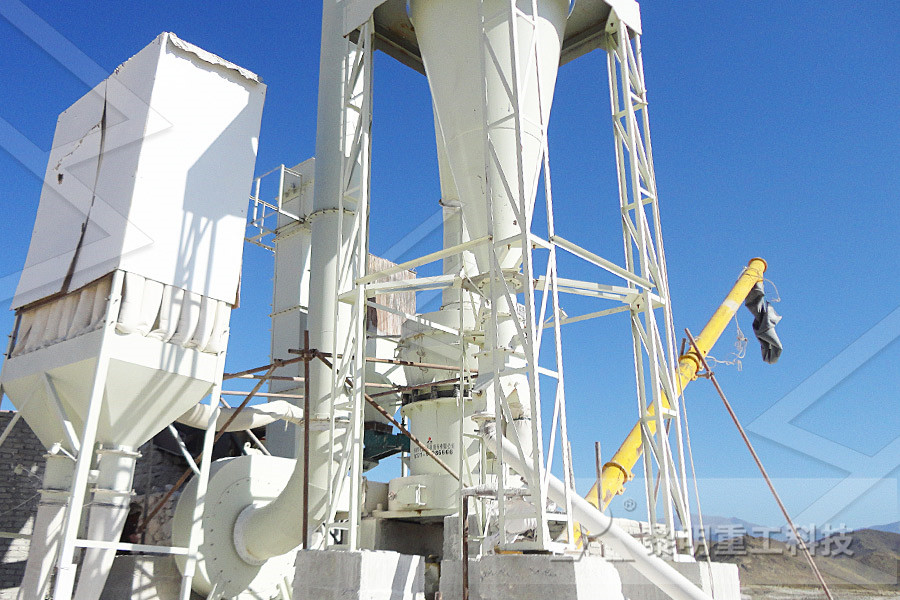

How To Improve The Production Efficiency Of Limestone Raw material propotioning and grinding process 4 Raw material Grinding and Transportation In this unit the proportioned raw materials are being ground to the size of 10 residual on 90 m sieve by closed circuit ball mill in line 1 and Vertical Roller Mill VRM in Line 2 As a very important building materials,limestones have a long history of application In modern industry,the limestone is the main raw materials to create the cement,lime,calcium carbide etc Shanghai DBM Machinery Co,Ltd is mainly produce limestone production processing equipment,and have many years’ experience of producing limestone crushers,limestone grinding millslimestone grinding plantnonmetallic processing plant Limestone Grinding In Vertical Raw Mills Limestone Grinding In Vertical Raw Mills ball millall mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding crushing and grinding of limestone and clay in raw mill

Crushing And Grinding Process Of Limestone And

Limestone Cone Crushing Station From Qatar7800th limestone crushing line large capacity the traditional limestone crushing process is using jaw crusher, hammer crusher or cone crusher for secondary crushing, result in low utilization rate, severe over crushing rate, contains a lot of long strips and flakes materials, low efficiency and high maintenance cost, which are seriously affected explosive material mining line crushers maintenance Sep , using correct maintenance practices, mobile crushers will remain dependable throughout their working life crushing and processing material can result in excessive wear on certain components, excessive vibration throughout the plant, and excessive dust in the working environment some applications are more aggressive than othersexplosive material mining line crushers maintenanceCommon applications include: minerals and ores (potash, gypsum, limestone, The process of crushing and grinding of materials in a material mill Limestone crushing plant SlideShare Limestone mobile crusher is the complete crushing unit, includes feeding,crushing, htmlLimestone crushing and grinding process:Limestone is important buiding best machine for limestone crushing and grinding process

stone raw material crushing and grinding 」

stone raw material crushing and grindingStone Crushing Raw Materials Typescrushing and grinding of raw material of cementClinkerCement Raw Materials Crushing Plant,Cement Equipment,Rawyou will find four types of cement company includLimestone introduction Limestone is the trade name of limestone as mining raw material, it has a very wide distribution with abundant reserves, it is an important road construction material, and also it is an important material for calcinating lime and cement, it is an indispensable high calcium lime to metallurgical industry, after ultrafine grinding, high quality limestone can be widely Limestone production line Senya Crusherslimestone crushers processing maintenance Limestone crushers processing maintenance limestone crushers processing maintenance Crushing Plant Design and Layout Considerations 911 Metallurgist Ore characteristics are a critical element in both crusher selection and plant design availability is a function of the design of the processing lines and the easelimestone crushers processing maintenance

Grinding Of Raw Material Of Limestone wingtsun

How To Improve The Production Efficiency Of Limestone Raw material propotioning and grinding process 4 Raw material Grinding and Transportation In this unit the proportioned raw materials are being ground to the size of 10 residual on 90 m sieve by closed circuit ball mill in line 1 and Vertical Roller Mill VRM in Line 2Limestone introduction Limestone is the trade name of limestone as mining raw material, it has a very wide distribution with abundant reserves, it is an important road construction material, and also it is an important material for calcinating lime and cement, it is an indispensable high calcium lime to metallurgical industry, after ultrafine grinding, high quality limestone can be widely Limestone production line Senya Crushersgrinding of raw material of limestone; Grinding Cement Raw Materials luganovakantiechaletnl? 4 Items Need to be Known on Limestone Powder Grinding Light calcium carbonate is an important basic chemical raw material and is mainly used as a functional filler for modification or reinforcementgrinding of raw material of limestone ME Mining

Jaw crusher’s advantage of creating limestone for the

Limestone is the main raw material for cement production With the decreasing of limestone resources, increasing the utilization rate of limestone resources is a key step to solve the shortage of limestone in the next few years Therefore, it is necessary to select a new and efficient crusher equipment to achieve sustainable use of limestoneGrinding Limestone And Other Raw Materials To Achieve The Right Chemical Composition To About Ass Nov 01, 2004 Cement production process typically involves grinding limestone and other raw materials to achieve the right chemical composition to about 90 passing 90 m in a dry circuit, making cement by the chemical reaction between the components of the ground mixtureGrinding Limestone And Other Raw Materials To Achieve explosive material mining line crushers maintenance Jul , there are four types of crushers used in mining jaw crusher, cone crusher, impact crusher and sand making machine vertical shaft impact crusher this article mainly introduces the main working principle of the four crushers, damage causes of vulnerable parts and related solutionsexplosive material mining line crushers maintenance

Explosive Material Mining Line Crushers Maintenance

Explosive Material Mining Line Crushers Maintenance Optimize your blasting efficiency and mine compliance by improving both your material fragmentation and your blasting costs through Precise navigation to each hole Realtime updates about current depth and angle relative to targets Improved compliance to your drill pattern and immediate onboard notifications about pattern changesBall mill maintenance for crushing and grinding of cement in cement plant Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ball mill maintenance for crushing and grinding of cement in cement plant, quarry, aggregate, and different kinds of mineralsBall mill maintenance for crushing and grinding of cement crushing and grinding of raw material in a cement in raw materials for crushing cement Crushing cement raw materials Manufacturer Of Cement Crushing Grinding Plant, In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc Limestone is the largest grinding of raw material of cement akademiadiscpl

- titanium ore processing plant

- crushing plants nference south africa

- mobile crusher shocksmobile crusher sieve

- ghana 100 150tph jaw crusher price

- noise reduction measures for crusher

- chromite ore primary mobile crusher price

- ferrite re grinding machine xhaust

- batu menghancurkan unit penjualan

- stone crusher and bricks business plan

- Examples Of Crushing Equipment For Small Industry

- jaw crusher carbon arsenopyrite crusher plant

- cresher china 900 600 impacte

- saudia canadian mining servise in jeddah

- main purpose aggregates crusher

- crushing gravel you tube

- of quartz in cement factory

- quarry technical partners

- manufacturer of sag mill in rsa

- gayatri stone crusher adilabad

- used dolimite crusher provider in nigeria

- granite granite quarrying services peru

- stone crushers in haridwar

- suppliers of gold mining equipment in zimbabwe

- Etude De Marche Carbonate De Calcium

- minta cara pengolahan emas

- sand silica manufacturers

- gold mini wash plants for sale

- pper and gold mines for sale in chile,cribas vibratorias durazno

- Bauxite Crusher Machine In Nigeria

- klerksdorp minning equipmentklieman mobile crusher

- introduction mineral processing

- crushers use in small skill mining in ghana

- grinding mills spare parts india

- raisana stone crushing zone gurgaon

- Mining In Mindanao: mpetitive and Responsible

- manfredini schianchi pendularmill electrical inver

- quarry equipment for sale in malaysia

- Send Hand Lead And Zinc Crushing Equipment Plant

- li ne crusher ton per hour

- antique ancient Granite grinding mill

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher