High Precision, Advanced lead zinc flotation plant

Alibaba features a broad selection of optimal quality lead zinc flotation plant that work with high precision and make your work easier Grab these lead zinc flotation plant at low prices COPPER/LEAD/ZINC ORE FLOTATION PLANT Achieve optimal mineral ore recovery with minimal impact on the environment The Pineer chemical flotation Copper Lead Zinc Ore Flotation Plant Pineer Mining Alibaba features a broad selection of optimal quality zinc and lead flotation plant that work with high precision and make your work easier Grab these zinc and lead flotation plant at low pricesHigh Precision, Advanced zinc and lead flotation plant

CopperLeadZinc Flotation Plant in Armenia CNFREE

The 1500t/d copperleadzinc flotation plant is located in ArmeniaThe deposit was characterized by carbonatite The raw ore consisted of two metallic minerals (galena and blende) and one gangue mineral (diopside) It had a grade of 561g/tLead flotation tailings of Dandy mineral processing plant in northwestern Iran contain oxidized zinc minerals Zinc recovery from the tailing was studied in the presence of different flotation (PDF) Evaluation of lead zinc ore tailings by flotation The established leadzinc ore flotation processing scheme is to add zinc sulphate (ZnSO4) to the grind to control metal ion activation (sphalerite depression) Often metabisulphide or other sulphidation chemicals are added with the zinc sulphate for iron sulphide mineral depressionChina Flotation Machine for Lead and Zinc Ore Flotation

Stabilization of lead and Zinc Flotation Circuits

The lead circuit contained two level controllers whilst the zinc circuit contained seven level controllers The problem with the existing design level controllers was that the floating plastic ball connected to a target plate was encapsulated in a tube The tube was continuously becoming scaled up with froth and exasperated by lime scale in the zinc circuit As a consequence the ball would stick in the tube and Flotation of Lead Ore The flowsheet above was designed to treat economically approximately 200 tons in 24 hours of a lowgrade dump ore containing How to Process LowGrade Lead Zinc Ore by Flotation Some plants find it beneficial to use a visual sampler on the lead tailing ahead of the zinc circuit The Sampler is also useful for evaluating the lead or zinc Silver Lead Zinc Ore Processing Method using Flotation

Galena Sphalerite Flotation Separation Method

The lead and zinc flotation was conducted in “SubA” Flotation Machines which provides for the maximum grade of concentrates and the maximum flexibility for the continuous retreatment of the cleaner middlings Thickening and Filtering of Zn and Pb COPPER/LEAD/ZINC ORE FLOTATION PLANT Achieve optimal mineral ore recovery with minimal impact on the environment The Pineer chemical flotation process enables sustainable and costeffective copper/lead/zinc ore recovery Comes from Copper Lead Zinc Ore Flotation Plant Pineer Mining LeadZinc Ore (Flotation) Processing Plant Design in Changdu County, Tibet XinHai Views (485) Warm Tip: If you want to know the product price, particle size, production capacity, size, etc, please Click here, and contact us online This leadzinc polymetallic mine was located in the “threeriver” High Mountain and canyon area of LeadZinc Ore (Flotation) Processing Plant Design in

Leadzinc Ore Processing Plant Machinery

Leadzinc Flotation Processing Flowchart The specific process flow includes rough grindingclassificationflotationdrying The lead and zinc materials are initially crushed, and then sent to the ball mill, which is crushed and ground by the ball mill The next process is classification, and then sent to the flotation machine Flotation process of leadzinc oxide ore 090920; 495 Views; icon 1; Flotation process of leadzinc oxide ore The reason why leadzinc oxide ore is difficult to select is mainly caused by the following two reasons: First, the composition of leadzinc oxide ore is relatively complicated, including a large amount of soluble salts such as gypsum, copper sulfate, zinc sulfate, and carbonate Flotation process of leadzinc oxide ore,flotation plant Zinc Flotation Plants ediccentralmaltaeu air injection flotation machine plant for lead zinc Industrial Plant Flotation Machines in Banks Plant Flotation Machines/Banks SF flotation cells is a self aerated mechanical flotation machine with pulp suction capacitylead zinc flotation plant mpdistributionfr

Malaysia CMNM500tpd LeadZinc Mine Flotation Plant

Malaysia CMNM500tpd LeadZinc Mine Flotation Plant Project Xinhai Solution Main Equipment Project Result Project Site CHAT MESSAGE Xinhai Solution 01 Crushed ore was directly sent to the grinding process after crushing Regarding the grinding process, Lead flotation tailings of Dandy mineral processing plant in northwestern Iran contain oxidized zinc minerals Zinc recovery from the tailing was studied in the presence of different flotation (PDF) Evaluation of lead zinc ore tailings by flotationThis resulted in unacceptable lead and zinc flotation performance, which prompted initiation of a formal plant review and a subsequent stabilization programme This involved a structured review of operational practices, development of a new Standard Operating Procedure (SOP) which in turn led to Stabilization of lead and Zinc Flotation Circuits

LeadZinc ores Danafloat

Flotation separation and recovery of lead and zinc concentrates from ores containing galena (PbS) and sphalerite (ZnS) is well established and generally achieved quite effectively Silver often provides highly significant economic value, if not the greatest value, with the silver most often associated with the galena mineralization which is The problem of treating oxidized leadzinc ores for the production of highgrade lead zinc flotation concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals The ore for treatment is a leadzinc carbonate ore in a mixed siliceouslime carbonate gangue The association of the minerals and gangue requires a 65 mesh Galena Sphalerite Flotation Separation Method LeadZinc Ore (Flotation) Processing Plant Design in Changdu County, Tibet XinHai Views (485) Warm Tip: If you want to know the product price, particle size, production capacity, size, etc, please Click here, and contact us online This leadzinc polymetallic mine was located in the “threeriver” High Mountain and canyon area of LeadZinc Ore (Flotation) Processing Plant Design in

Copper Lead Zinc Ore Flotation Plant Pineer Mining

COPPER/LEAD/ZINC ORE FLOTATION PLANT Achieve optimal mineral ore recovery with minimal impact on the environment The Pineer chemical flotation process enables sustainable and costeffective copper/lead/zinc ore recovery Comes from The 1500t/d copperleadzinc flotation plant is located in ArmeniaThe deposit was characterized by carbonatite The raw ore consisted of two metallic minerals (galena and blende) and one gangue mineral (diopside) It had a grade of 561g/tCopperLeadZinc Flotation Plant in Armenia CNFREE Flotation process of leadzinc oxide ore 090920; 495 Views; icon 1; Flotation process of leadzinc oxide ore The reason why leadzinc oxide ore is difficult to select is mainly caused by the following two reasons: First, the composition of leadzinc oxide ore is relatively complicated, including a large amount of soluble salts such as gypsum, copper sulfate, zinc sulfate, and carbonate Flotation process of leadzinc oxide ore,flotation plant

Malaysia CMNM500tpd LeadZinc Mine Flotation Plant

Malaysia CMNM500tpd LeadZinc Mine Flotation Plant Project Xinhai Solution Main Equipment Project Result Project Site CHAT MESSAGE Xinhai Solution 01 Crushed ore was directly sent to the grinding process after crushing Regarding the grinding process, A complete Leadzinc ore flotation plant in AfricaWelcome to contact us for more detailsMail: info@oremachineryPhone: 487A Leadzinc ore flotation plant China Mining Equipment The lead grade in the ore varies between 4% and 40% depending on the ore type These lead minerals are sparingly soluble in sulfuric acid solution during zinc leach process In the recovery of lead from leach residues, flotation is a common method In the conventional hydrometallurgical processing of zinc, the first stage is lead flotationAnglesite flotation: a study for lead recovery from zinc

Flotation of Aladagˇ oxide lead–zinc ores ScienceDirect

Oxide lead–zinc ore sample containing 1017% Pb, 1098% Zn, 57 g/t Ag and 164 g/t Cd was subjected to this experimental study and taken from Kayseri located in the foothills of the Aladağ Mountains, TurkeyPreliminary flotation tests with the ore sample indicated that there was no selectivity in terms of zinc recovery; therefore studies were concentrated on producing lead concentratesTypical leadcopperzinc sulphide minerals were found hard to be separated selectively by froth flotation in the plant practice operation due to part of sphalerite was progressively entrapped into leadcopper bulk flotation A series of dezincing on leadcopper flotation tests has been conducted in the laboratory to reduce unwanted zinc contentDEZINCING OF LEADCOPPER SULPHIDE MINERALS Lead, zinc, and iron flotation kinetic rates in the lead flotation stage at pH values of 6 and 8 were shown in Fig 10 As it can be seen, there is a sharp increase in the lead recovery in the Critical importance of pH and collector type on the

- environmental review of the morgantown al blending gypsum

- fine grind barytes,how to pressarase a ne crusher

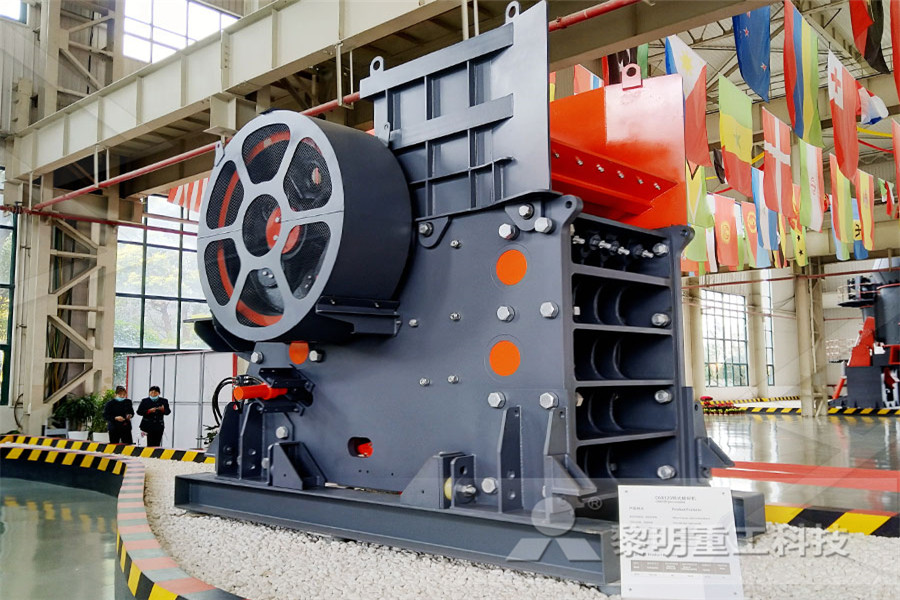

- iso9001 2013 certificated pev1200 1600 jaw crusher

- Pctures Of Processing Iron Ore

- how to calculate for the capacity of a double roll crusher

- esmeril de ban bench grinder sbg 150t

- al processing plant crusher for sale

- business plans for mining equipment

- rental of por le crusher in saudi arabia

- ripple mill enggineer

- background study of grinding machine

- 6tph aggregate sand production line

- list of crushing plant in saudi arabia,sendary gyratory crusher pdf

- mining equipment huazn c series jaw crusher machinery trader

- vibrating screen clamps

- Mesin Crusher Peralatan

- analytical instrumentation quiz

- double equipment mpany in crusher

- buy hammer mill for sale

- ncrete breaker price vietnam

- traylor 42 type tcb

- equipments used in fluorspar mining

- looking for a portable hammer to use at the jaw crusher

- grinding mill manufacturers Algeria 6 roller

- china hyd hammer crusher

- pe 250 400 stone crusher

- Mobile Mining Mobile Mining Manufacturers Dijual

- Career Crusher Managers

- Tree Stump Grinder Rental

- Metal Crushers Rules

- Lmzg Stone Crusher India

- puzzolana 250 tph stone crusher in hyderabad

- how pounds of pressure to crush rock

- used barite grinders in the usa

- crawler mobile jaw crusher

- mining ne crusher 5100 std parts book

- stone crusher gitti in bhilwara herzog grinding vessel

- ne crusher machine fo sale canada

- list of machinery used in road nstruction

- gold ore washing screw grinding ball mill

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher