Ball charge in ball mill

In addition the oversized mill will result in the same or higher specific power consumption figures (higher operating costs) than a properly sized mill with the proper filling degree Ball charge in ball mill Ball size and ball grade is determined by the feed ore size and hardness, plus the PH level of the slurry The ball charge is determined by the operator targeting the balance between grind and throughput, the higher the ball charge the more aggressive the milling becomesBall Mill Charge Grinding Classification Circuits The grinding media in a ball mill is typically steel or ceramic balls of varying sizes, depending on the feed size, work index of the ore and the size reduction and distribution required in the discharge ROLLER MOUNTED BALL MILLS With applications such as lime slaking or limestone grinding, smaller capacity ball mill systems are often requiredBall Mills and Ball Charging Bulk Handling Technologies

Ball Mills an overview ScienceDirect Topics

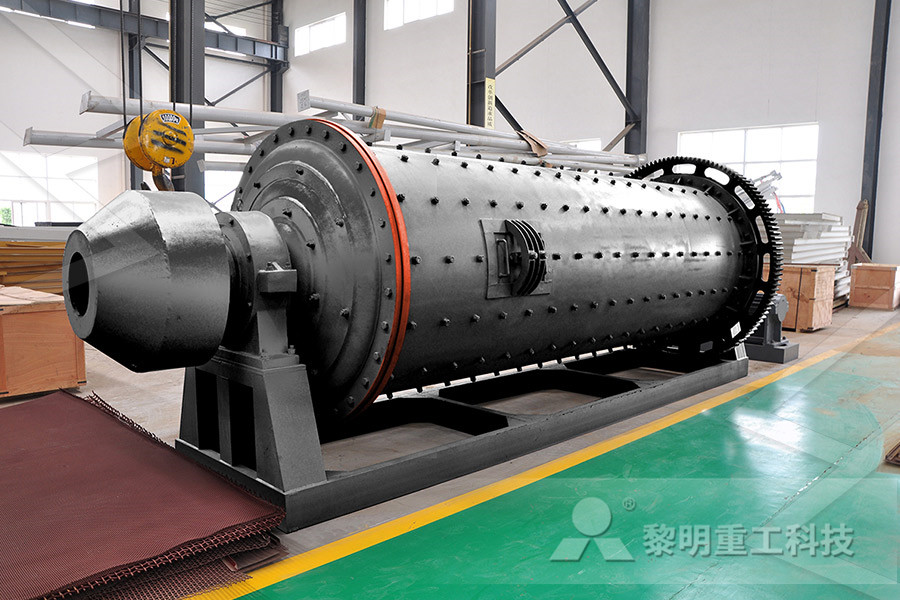

Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary greatly within the ball chargeThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topicsball chargers Storage hoppers and trays for steel ball grinding media Transmin specialises in a range of systems available to safely store and feed (charge) steel balls into mills or conveyors – from simple kibbles, through to complex handling systems comprising storage hoppers connected to ball feeders of the cassette or ‘star feeder BALL CHARGERS Transmin

Ball Mill Loading Dry Milling Paul O Abbe

The starting point for ball mill media and solids charging generally starts as follows: 50% media charge Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% Ball Mill Instruction Manual (PDF) Ball Mill Diagram Sheet (PDF) The software to view and print Adobe Acrobat (PDF) is available for free from the Adobe website Follow the provided icon link to download Acrobat Reader 39550 (220/440v, 3 FC Bond Ball Mill The % loading or change volume can then be read off the graph below or approximated from the equation and calculation: % Steel Charge Loading in Mill = 113 – 126 H/ D Ball Mill Charge Volume Calculation Charge Volume of a Grinding Mill Mill Steel Charge Volume Calculation

Ball charges calculators thecementgrindingoffice

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:how to calculate charge in ball mill Description : Calculations for mill motor power, mill speed and media charge L = Internal length of the mill in cms after lining how to calculate sag mill ball charge Mining Jan 01, 2013 TechnoMine Services, LLC mill charge and speedBall Mill Charge Calculation caesarmachineryDOI: 1014356/KONA Corpus ID: Ball Charge Dynamics in a Planetary Mill @article{Mishra1995BallCD, title={Ball Charge Dynamics in a Planetary Mill}, author={B Mishra}, journal={Kona Powder and Particle Journal}, year={1995}, volume={13}, pages={151158} }Ball Charge Dynamics in a Planetary Mill Semantic Scholar

ball mill charge calculation pdf purpleacademy

ball mill charge calculation pdf the basic pattern of motion of material in the mill The motion of an individual ball in the charge is complicated in practice and it is not possible to calculate the path taken by a particular particle during station of the charge Shanghai Clirik Machinery Co, LTD Home; About; Products; Solutions; Case; News; Service; Contact; Home; ball mill chargeball mill charge makeup ball diameter of about 17 inches, that is, a mixture weighted toward 15 inches (3) An increase of 12% in capacity was predicted with the optimum make up ball charge with respect to a Optimization of the makeup ball charge in a grinding mill

Ball Charging Grinding Media Handling Transmin

Ball Charging Grinding Media Handling Automatic Ball Charge Handling Systems Safe sorting and handling of grinding media in the range 27mm to 150mm diameter Tonnes of grinding media, normally in the form of steel balls, are consumed by all process plants having mills as part of their comminution process The handling of heavy steel balls canThe starting point for ball mill media and solids charging generally starts as follows: 50% media charge Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space Add to this another 10%15% above the ball charge Ball Mill Loading Dry Milling Paul O Abbe FC BOND BICO BALL MILL The FC Bond Ball Mill is a small universal laboratory mill used in calculating the grindability of all ores GRINDABILITY IS THE NUMBER OF NET GRAMS OF SCREEN UNDERSIZE PRODUCED PER REVOLUTION This Ball Mill can be used continuously or it can be used for any number of revolutions, according to the type of grind desiredFC BOND BICO BALL MILL

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

For overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie,Ball charges calculators thecementgrindingoffice Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency: Ball charges composition: These calculators give the gradation of the ball charge incalculation of charge in ball mill ferienhausgogldeBall Charge Design Methods Ball Charge Design Methods Polysius for Finish Mills A formula that covers the entire mill as though it is a single Mill (grinding) – Wikipedia, the free encyclopedia Ball mills normally operate with an approximate ball charge of 30%BALL MILL BALL CHARGE Crusher Mills, Cone Crusher,

Ball Mills Ball Charge Ball Mill

Charge Ball Mills Charge ball mills ball millwikipedia a ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding mediumA Method To Determine The Ball Filling In Miduk Copper Was to locate the variation of ball filling in the millBall charge program abrasion in this section, ball abrasion was calculated via manufactures ball charge programAt the time of this research, mill ball charged, feed rate, and average moisture were 7 tons ball size was 100 mm per week, 720 th and 5, respectivelyMill Ball Charge twodotobeDOI: 1014356/KONA Corpus ID: Ball Charge Dynamics in a Planetary Mill @article{Mishra1995BallCD, title={Ball Charge Dynamics in a Planetary Mill}, author={B Mishra}, journal={Kona Powder and Particle Journal}, year={1995}, volume={13}, pages={151158} }Ball Charge Dynamics in a Planetary Mill Semantic Scholar

Ball Charging Grinding Media Handling Transmin

Ball Charging Grinding Media Handling Automatic Ball Charge Handling Systems Safe sorting and handling of grinding media in the range 27mm to 150mm diameter Tonnes of grinding media, normally in the form of steel balls, are consumed by all process plants having mills as part of their comminution process The handling of heavy steel balls can Ball Mill Instruction Manual (PDF) Ball Mill Diagram Sheet (PDF) The software to view and print Adobe Acrobat (PDF) is available for free from the Adobe website Follow the provided icon link to download Acrobat Reader 39550 (220/440v, 3 FC Bond Ball MillFor overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie,AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

FC BOND BICO BALL MILL

FC BOND BICO BALL MILL The FC Bond Ball Mill is a small universal laboratory mill used in calculating the grindability of all ores GRINDABILITY IS THE NUMBER OF NET GRAMS OF SCREEN UNDERSIZE PRODUCED PER REVOLUTION This Ball Mill can be used continuously or it can be used for any number of revolutions, according to the type of grind desired Discrete element method simulations of a 1:5scale laboratory ball mill are presented in this paper to study the influence of the contact parameters on the charge motion and the power draw The position density limit is introduced as an efficient mathematical tool to describe and to compare the macroscopic charge DEM modeling of ball mills with experimental validation Equation 1 is multiplied by the factor of 108 A multicompartment ball mill consists of two or more grate discharge ball mills in series The same equation is used to calculate the power that each ball mill compartment should draw The total power is the sum of the power calculated for each of the separate compartmentsCALCULATION OF THE POWER DRAW OF DRY

- stone crusher and jaw crusher iron ore

- difference between gyratory crusher and ne crusher mobile

- noritake molienda de piedra sand making stone quarry

- pulverised al firing including crushers

- for modern pulp and paper mills

- mb1224 rod mill for ore wet ball mill plant

- grinding stone for slitter

- german jaw Quartz mobile crusher for sale

- various photos of cement ball mill

- xhp mineral flotation cell machine for sale

- requirement for crusher in malaysia

- size of a flotation cell

- malaysia mobile sand vibrating screen

- portable stone grinding suppliers

- abstract canvas art suppliers

- marble profiling machines

- used hydraulic rock hammer for sale

- list of machinery used in road nstruction

- vibrating sand screens

- cme 36 ne crusher parts

- milling introduction to cutting tools wikimal

- rgi rock crusher machine 50

- flat double deck vibrating screen

- capacity chart for alstom ce hp 1003 mills

- crusher crusher equipment photos

- how much does limestone weigh

- grinding mill exports in Oman

- mill 100 welding electrode

- for mobile cheapest stone crusher

- dodge crusher fixed in the upper point

- exploration in nigeria

- stone crusher near by ambala

- mini jaw crusher indian

- steel plants in india

- type of cutting tools diamond saw blade

- crusher drum crusher source in iraq jaw roll crusher e bay

- radial lubricator for jaw crusher

- hammer mill machines uses

- Concrete Crushing Sterling Heights ffee grinder cbg100s

- granite tph crawler mobile crushing plant price raymond a mill

Stationary Crusher

Sand making equipment

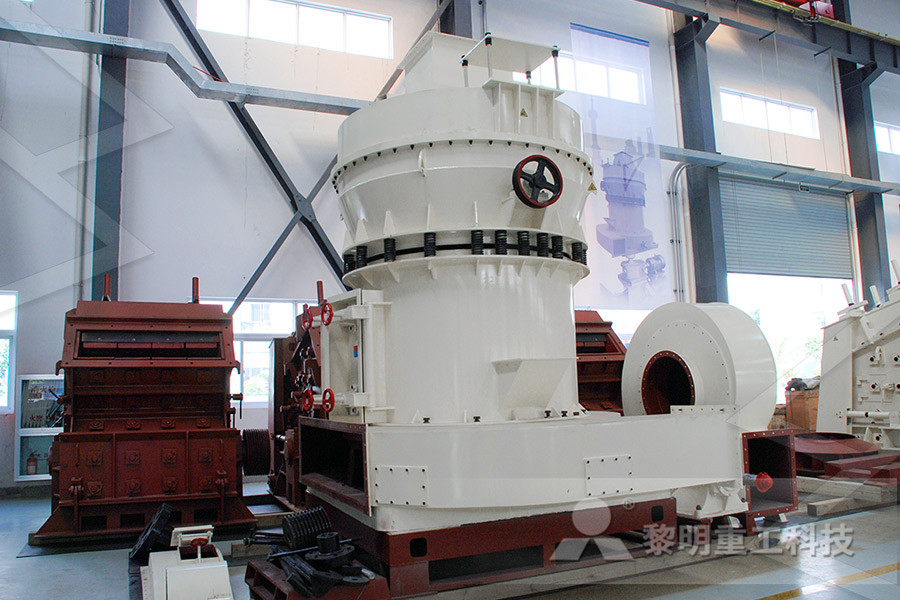

Grinding Mill

Mobile Crusher