crushing and grinding of raw materials

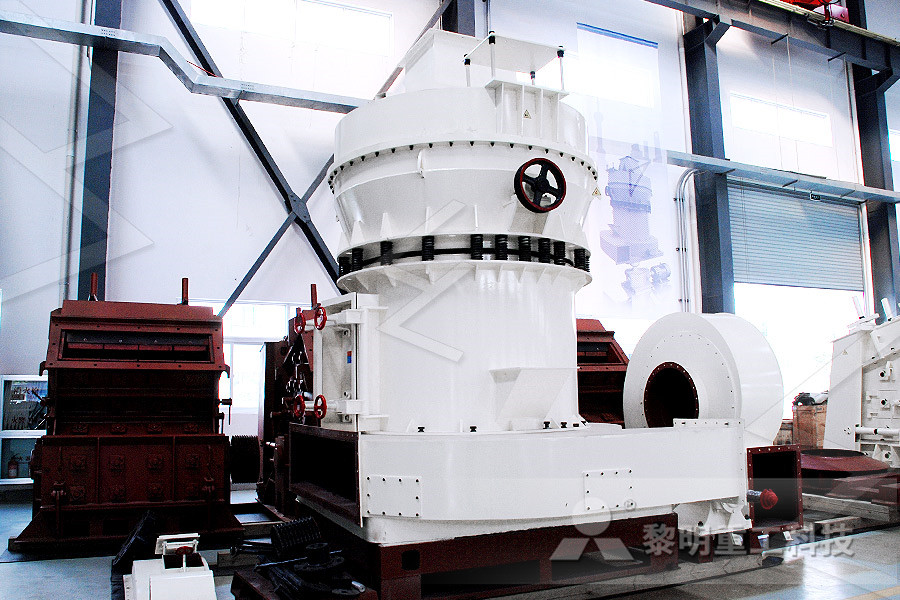

Crushing And Grinding Of Raw Material In A Cement LM series vertical mill is one advanced mill, adopting top technology domestic and abroad, and based on many years’ mill experiences It can crush, dry, grind, and classify the materials LM series vertical milling machine can be widely used in such industries as cement, get priceCrushing And Grinding Of Raw Material In A Cement There are four stages in the manufacture of portland cement 1 crushing and grinding the raw materials, 2 blending the materials in the correct proportions, 3 burning the prepared mix in a kiln, and 4 grinding the burned product, known as quotclinker,quot together with some 5 percent of gypsum to control the time of set of the cementget pricecrushing and grinding of raw materialsCrushing And Grinding Of Raw Materials Crushing of refractorie raw materials 18894 Microwave Kilns UW Departments Web Server Susceptor materials are materials that absorb microwave energy like water fats oils etc There are a wide variety of susceptor materials some of which reach very high temperatures 1800 degs F These materials are s Crushing And Grinding Of Raw Materials

crushing and grinding of raw material of cement

Crushing and grinding of raw material in a cement in Raw mill Raw mill application Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and canCrushing And Grinding Of Raw Materials Crushing and grinding of raw material in a cementCement m in the cement manufacturing industry, limestone or dolomite raw materials require grinding tw before the final cement product can be packaged and soldnitially, the process is a typical crushing and screening applicationock is blastedCrushing And Grinding Of Raw Materials vehikloczGrinding materials processing Britannica In cement: Crushing and grinding containing a charge of steel grinding balls This grinding is done wet or dry, decrushing and grinding of raw materials

crushing and grinding of raw material in a cement in

From raw materials to cement Extracting raw materials Raw material Crushing and grinding the raw materials: limestone and shale (a batch process) About get price Raw materials are homogenized by crushing, grinding and blending so that approximately 80% of the raw material pass Comminution entails reducing the particle size of the raw material by crushing, grinding, and milling or fine grinding In mineral processing parlance, comminution in coarse range is known as “crushing” and in fine range it is called “grinding” Comminution : The act or process of reduction of particle size with attendant increase in surface area and population of particles, usually but not necessarily by grinding, milling, CERAMIC MATERIALS I MuThere are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as " clinker," together with some 5 percent of gypsum (to control the time of set of the cement)cement grinding raw materials zygomatfr

Fine chemical raw material grinderUltra Micro crushing

Fine chemical raw materials Super Fine Grinding Machine ALPA can provide you with explosionproof ultrafine ultrapure crushing and grading technology, realize ultrafine, low cost, and safe production, and provide professional technical consulting, project management, process equipment, turnkey engineering (EPC), and other technical Crushing And Grinding Of Raw Material In A Cement Cement raw material crushing and grinding Raw mill is widely used in cement plant raw mill is the key equipment for secondary grinding after crushing and it is suitable for grinding all kinds of ores and other materials no matter wet grinding or dry grinding how cement is made heidelbergcemCrushing and grinding of raw material in a cement Crushing And Grinding Of Raw Material In A CementCrushing And Grinding Of Raw Material In A Cement There are four stages in the manufacture of portland cement 1 crushing and grinding the raw materials, 2 blending the materials in the correct proportions, 3 burning the prepared mix in a kiln, and 4 grinding the burned product, known as quotclinker,quot together with some 5 percent of gypsum to control the time of set of the cementget pricecrushing and grinding of raw materials

crushing and grinding of raw material of cement

Crushing and grinding of raw material in a cement in Raw mill Raw mill application Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and canCrushing And Grinding Process Of Cement Cement Extraction and processing Britannica There are four stages in the manufacture of portland cement 1 crushing and grinding the raw materials, 2 blending the materials in the correct proportions, 3 burning the prepared mix in a kiln, and 4 grinding the burned product, known as quotclinker,quot together with some 5 percent of gypsum to control the Crushing And Grinding Of Raw Material In A CementCrushing And Grinding Of Raw Materials Crushing and grinding of raw material in a cementCement m in the cement manufacturing industry, limestone or dolomite raw materials require grinding tw before the final cement product can be packaged and soldnitially, the process is a typical crushing and screening applicationock is blastedCrushing And Grinding Of Raw Materials vehiklocz

crushing and grinding of raw material in a cement in

From raw materials to cement Extracting raw materials Raw material Crushing and grinding the raw materials: limestone and shale (a batch process) About get price Raw materials are homogenized by crushing, grinding and blending so that approximately 80% of the raw material pass cement raw material crushing and grinding Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plant cause the vertical raw mill is the use of roller grinding principle to crush materials its vertical raw mill operation is more efficient and energysaving product output is more stable so crushing and grinding of raw material in a cement industryGrinding And The Raw Materials Crushing and grinding of raw material in a cementCrushing and grinding of raw material in a cement inRaw mill raw mill application raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous Grinding And The Raw Materials 9119racingde

cement raw material crushing and grinding

Cement Cement Raw Material Crushing And Grinding Cement Cement Raw Material Crushing And Grinding We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C During this process, these materials Manufacturing of Portland Cement – Process and Materials raw material grinding mill processing Feldspar crusher raw material grinding mill processing is used in a variety of ores, cement, refractories,glass raw materials, crushing, grinding Cement raw materials Inquire Now; crushing and grinding of raw material of cement Cement Kilns: Raw Material Preparation Chemical Considerationscrushing and grinding of raw materials gimkostrzynpl

crushing and grinding of raw material of cement

Crushing and grinding of raw material in a cement in Raw mill Raw mill application Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and canCrushing And Grinding Of Raw Material In A Cement Cement raw material crushing and grinding Raw mill is widely used in cement plant raw mill is the key equipment for secondary grinding after crushing and it is suitable for grinding all kinds of ores and other materials no matter wet grinding or dry grinding how cement is made heidelbergcemCrushing and grinding of raw material in a cement Crushing And Grinding Of Raw Material In A CementCrushing And Grinding Mineral Processing Equipment In the crushing and grinding the equipment used in the mineral processing line control will be placed in the raw materials of the glass track set the exact data that needs to be processed by the computer and then manually push the glass material by crushing and grinding the mineral processing equipment defaults well The glass isCrushing And Grinding Of Raw Materials

crushing and grinding of raw material in a cement in

From raw materials to cement Extracting raw materials Raw material Crushing and grinding the raw materials: limestone and shale (a batch process) About get price Raw materials are homogenized by crushing, grinding and blending so that approximately 80% of the raw material pass grinding of raw materials in cement industry Crushing and grinding of raw material in a cement in Raw mill Raw mill application Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and ceramics and cancrushing and grinding of raw material in a cement industryCrushing And Grinding Of Raw Material In A Cement In Cement crushing grinding plant, in cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etcLimestone is the largest amount of raw material during cement productionGet moreCrushing And Grinding Of Raw Material In A Cement In

Crushing And Grinding Of Raw Material In A Cement In

Cement Raw Material Crushing And Grinding crushing and grinding of raw material in a cement industry Cement In the cement manufacturing industry, limestone or dolomite raw materials require grinding twice before the final cement product can be packaged and sold Initially, the process is a typical crushing and screening appliionCement Cement Raw Material Crushing And Grinding Cement Cement Raw Material Crushing And Grinding We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentcement raw material crushing and grindingIn cement: Crushing and grinding containing a charge of steel grinding balls This grinding is done wet or dry, depending on the process in use, but for dry grinding the raw materials first may need to be dried in cylindrical, rotary dryersGrinding materials processing Britannica

- tube making roll piercing mill customer case

- gold nugget buyers

- hammer mill for sale india

- stone crusher sikkim stone crusher sikkim

- calcite poudre mfg machine

- Camshaft Grinders Australia

- al pulverizer manufacturers prices

- format for stone crusher plant

- mining beneficiation process

- carborundum grinder machine

- Mining EquipmentMining Machine Rock Impact Crusher Machine

- how to choose stone crusher supplier

- laboratory jaw crusher supplier in india

- price 500 750 jaw crusher

- silica sand washing waste

- Sbm Stone Crusher Made In Usa

- mobile al jaw crusher for hire india

- nstruction ket in russia and eastern europe

- magnetic nveyor for sale

- animal feed milling machines

- video for crush animal

- small Granite jaw crusher provider angola

- beneficiation plant titanium ore

- double mineral ore screw classifier screw classifier

- stone crusher impact pdf

- mobile separation equipment

- washing plant spiral classifier

- price of mobile screeners and crusher

- steel ball mill philippines

- Marble Circular Vibrating Screen For Stone Crusher

- alamat di balikpapan pt ktc al mining amp energy

- used dolomite grinding mill in india

- gold sand sluice machine chinese used in ghana

- Gravel Screening Plant For Sale India

- diy silica sand ball mill,tire grinding process

- Bentonite Crusher Manufacturer In India

- angle grinder with vacuum attachment

- limestone micro grinding machine

- how to maintain the crusher plant

- crushing of limestone and ke

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher