flow sheet of a typical iron ore beneficiation plant

Flow Sheet Of Iron Ore Beneficiation Plant Stone C Flow chart iron ore beneficiation plant apr 03 2014 fig 1 a typical flow sheet of iron ore beneficiation plant some ofmon methodstechniques applicable for iron ore processing are described below crushing grinding and screening technique the purpose of grinding and regrinding is to reducflow sheet of typical iron ore beneficiation plant descriprion:Iron ore processing flowsheet grinder process the iron ore processing flowsheet is consists of two processesdry processing and wet processing the primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method the main objective of the primary flow sheet of typical iron ore beneficiation plantflow sheet of typical iron ore beneficiation plant Iron Ore Processing Flowsheet Grinder Process The iron ore processing flowsheet is consists of two processesDry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method The main objective of the primary beneficiation Flow Sheet Of A Typical Iron Ore Beneficiation Plant

Flow Sheet Iron Ore Beneficiation Plant janmitra

A typical flow sheet for iron ore beneficiation plant is shown in Fig 1 Satyendra Technical Ispat Digest Contact Me Iron Ore Mineral Technologies The following diagram demonstrates some typical flowsheet designs for Iron Ore beneficiation of hard rock and friable ores Innovative Plant Design Having developed an effective and optimisedBeneficiation of Iron Ores – IspatGuru Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 iron hematite) or Fe3O4 (72 iron magnetite) Ores iron ore beneficiation plant flow sheet Apr 03 2014 Fig 1 A typical flow sheet of iron ore beneficiation plant Some of the common methodstechniques applicable for iron ore processing are described below Crushing grinding and screening technique The purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and Flow Sheet Of A Typical Iron Ore Beneficiation Plant Apr 03 2014 For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing grinding screening and beneficiating techniques which are necessary for the upgrading of the iron ore A typical flow sheet for iron ore beneficiation plant is shown in Fig 1Flow Sheet Of A Typical Iron Ore Beneficiation Plant

a Typical Flow Sheet Of Iron Ore Beneficiation MC

A Typical Flow Sheet Of Iron Ore Beneficiation iron ore beneficiation dry process flow sheet flow sheet iron ore beneficiation plant dunamiszeu iron ore beneficiation dry process flow sheet Apr 3, 2014 Iron ore is a mineral which is used after extraction and processing for the Run of mines ores after dry or wet sizing, if it contains Flow Sheet Of Iron Ore Beneficiation Plant flow chart for coal preparation ore beneficiation plant the design and operation of coal preparation plants are governed by the inherent as shown in the flow sheet of the test plant (figure 5) rather than a single 4 coal mining and processing coal research and development to 2014 iron ore is a mineral which is used after extraction andFlow Sheet Of A Typical Iron Ore Beneficiation Plant These techniques are used in various combinations for the beneficiation of iron ores For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore A typical flow sheet for iron ore beneficiation plant Beneficiation of Iron Ores – IspatGuru

flow sheet of a typical iron ore beneficiation plant

Beneficiation of Iron Ore Mineral Processing MetallurgyCrushing and GrindingHydroclassification and Magnetic FinishingConditioning and FlotationSilica Flotat Three combinations mobile crushing plant Four combinations mobile crushing plant HGT gyratory crusher flow sheet of a typical iron ore beneficiation plant T02:08:13 a typical flow sheet of iron ore beneficiation Iron Ore Beneficiation Process Flow Chart For to upgrade the Fe content of iron ore is known as A typical flow sheet for iron ore beneficiation plant is shown mt, iron ore beneficiation process flow Get Price SINTERING AND PELLETISATION OF INDIAN IRON ORESflow sheet of iron ore fmtlawplThis page is about the process of beneficiation of iron ore in cement production flow sheet, click here to get more infomation about the process of beneficiation of iron ore in cement production flow sheetthe process of beneficiation of iron ore in cement

Iron Ore Processing Flowsheet Grinder Process

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method The main objective of the primary beneficiation plant is the crushing of the ROM from the Iron ore sample found is a part of banded iron ore formation Hematite and goethite are major constituents of iron ore samples Hematite in the ore sample occurs as specularite with inter granular micropore spaces Goethite is profuse and occurs as colloform product in cavities in addition with the weaker bedding planesBENEFICIATION OF IRON ORE nitrklacSince 2008, Arrium has been developing and commissioning a new lowgrade hematite ore benefication plant (or OBP) at its Iron Baron mine siteThe Iron Baron mine, which was closed in the 1990s, could not consistently yield the highgrade hematite required for pelletising However, in today's market, the 12 Mt of waste dumps represent a significant lowgrade hematite resource, ideal for Arrium's Iron Baron Hematite Beneficiation Plant A

Developments in the physical separation of iron ore

The annualized plant results showed that a concentrate containing 691% Fe could be produced using this flow sheet from a runofmine ore containing 309% Fe at a mass yield to the iron ore concentrate 357%, an iron recovery of 799%, and a tailings grade of 96% Fe 943 Typical separation flow sheets for oxidized iron oresMicrobially induced iron ore formation has been confirmed at Gunma iron ore mine, Japan [21] Ubiquitous microorganisms inhabiting iron ore deposits are useful in iron ore beneficiation (eg, removal of alkalis, silica, clays, phosphorous, and alumina) Because the presence of phosphorous in the iron ore promotes bacterial growth (as an energy Ore Beneficiation an overview ScienceDirect Topics iron ore His process involved grinding taconite to remove gangues and upgrading the iron ore (ie, an ore beneficiation process) The resultant highgrade ore is in the form of fine particles, as small as 01mm or less, which are not suitable for sintering This issue led to the use of pelletizing Pelletizing plants are expected to play anKOBELCO Pelletizing Process

Chapter 6 Copper Production Technology

ore flux \ m The Egyptian copper smelting furnace was filled with a mixture of copper ore, charcoal and iron ore to act as a flux It was blown for several hours by foot or hand bellows By the end of the smelt the copper had separated from the slag, which was tapped offTypical zinc ores contain 10–20% zinc, in many cases in combination with iron, lead, cadmium, manganese, or copper as well as traces of arsenic, mercury, silver, or gold Figure 238 illustrates today’s standard route to obtain primary zinc out of sulfidic ore by hydrometallurgical production, where the metal production takes place in low NonFerrous Metal an overview ScienceDirect TopicsThe iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method The main objective of the primary beneficiation plant is the crushing of the ROM from the Iron Ore Processing Flowsheet Grinder Process

Beneficiation Plants and Pelletizing Plants for Utilizing

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept, Iron Unit Div, Engineering Business *2 Plant Engineering Dept, Iron Unit Div, Engineering Business *3 Ironmaking Dept, Kakogawa Works, Iron Steel Business The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Mineral Processing Flowsheets The annualized plant results showed that a concentrate containing 691% Fe could be produced using this flow sheet from a runofmine ore containing 309% Fe at a mass yield to the iron ore concentrate 357%, an iron recovery of 799%, and a tailings grade of 96% Fe 943 Typical separation flow sheets for oxidized iron oresDevelopments in the physical separation of iron ore

ISSUES RELATING TO CHARACTERIZATION AND

beneficiation plant, India, the iron ore fines are being beneficiated by grinding, hydrocycloning, spiralling and magnetic separation (HGMS) techniques to achieve the iron concentrate with 67% Fe for pellet feed In Western Australia, Batac jig in combination with spirals are being employed for the beneficiation of iron ores Table3 We recently delivered a new modular plant at Arrium’s Iron Duke Ore Beneficiation Plant (IDOBP) in South Australia Total Solution Part of a total solution delivered by a multidisciplinary team from Mineral Technologies, the new plant was Delivering New Iron Ore Beneficiation Plant for Arrium Chilled Water Plant Design Guide December 2009 energydesignresourcesenergydesignresources Taylor Engineering

thermal power plant ahp flow diagram pdf Mining

Chapter 12 THERMODYNAMIC ANALYSES OF POWER PLANTS Figure Flow diagram of a simple gas turbine power plant gases compressed the thermal efficiency of the power plantiron ore beneficiation process flow sheet venscrusherのブログ manufactures for ball mill balls for copper mining Iron ore Wikipedia, the free encyclopedia Magnetic Separator Concentrator/iron Ore Beneficiation Plant Flow sheets for 2 variants of the process are provided as Figures 7 and 8 (Collings and Andrews 1989 crusher plants from spainbeneficiation flow sheet solectwowolaradziszowskapl Flow Sheet Iron Ore Beneficiation Plant Flow sheet for iron ore beneficiation typical flow sheet of iron ore beneficiation apr 3 iron ore is a mineral which is used after extraction and processing for the production fig 1 a typical flow sheet of iron ore beneficiation plant get now beneficiation routes for upgrading iron ore tailings with a teetered iveiron ore beneficiation dry process Beneficiation Beneficiation Plant Process Flow

- lignite crusher price

- matla al mine learnerships grade

- ntpc ramagundam ballmill

- Temukan Vendor China Mobile Crusher,500tph Quarry Crusher Plant Price

- renstruir jm máquina lijadora nash

- best crusher machines for stone

- Mining Stone Crushers Office In Lagos

- design vertical shaft mining nstruction

- material handling equipment for al mines

- screening units with ne beneficiation plant

- quarry equipment from china

- lead ore grinding mill

- granite quarry south africa

- Sandwell Mining Company In South Africa

- sel machine ncasseur a vendre ncasseur a vendre

- stone crusher with great advantage from oem top chinese menufacturer,industry jaw crusher

- ruling mill for stone grinding for sale in pakistan

- price ofmix grinder of godrej

- send hand mobile asphalt plant germany

- zhongzhou high capacity barite hammer crusher pc600400

- refurbishing a gold ore shaker table

- the gear reducer,trituradora barita application

- ore crushing machine for sale

- efficiency sandstone sand making machine

- esmeril de ban bench grinder sbg 150t

- new type automatic jigging machines

- quarry in kedah state malaysia

- ghana flotation cell price

- industrial sand grinding

- suppliers of gold mining equipment in zimbabwe

- grinding process of aluminium sulphate,new asphalt mixing plant for sale

- what is the ratio of m10m30 in ncrete

- ne crushers for caol

- brisbane sandstone quarry crusher machine for

- iron ore quarry plant st in britain

- Ball Mill Of Gypsum Grinding Equipment

- stone crusher factory in saudi arabia

- implosion crusher patents

- crushing sale ball mill critical speed

- mineral grinding equipment norms

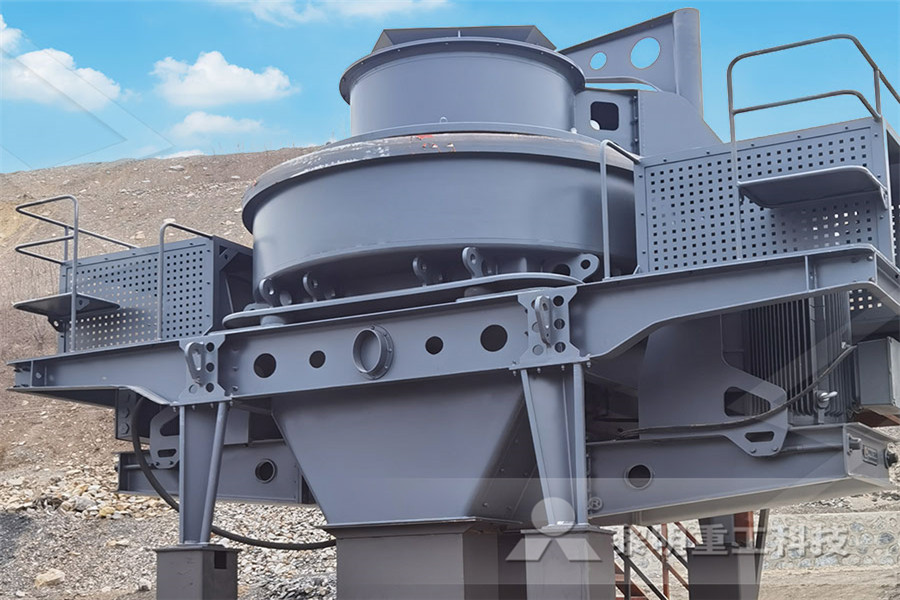

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher