hematite ore calcination heprocrcz

Calcination Process Technology Of Hematite Ore Cfd analysis of an induration cooler on an iron ore grate Calcination process technology of hematite ore reductive calcination is carried out in the reducing atmosphere, resulting in reducing agent of reducing atmosphere is usually c, co and h2 the calcination is suitable for hematite and limonite for hematite, rotary kiln make ores heat in 550Hematite (αFe 2 O 3) nanoparticles were synthesized from the solution of FeCl 36H 2 O and NaOH in water using microwaveassisted calcination method The syntheses were initially carried out by microwave heating and completed by a calcination process using a simple heating Syntheses of Hematite (αFe2O3) Nanoparticles Using The duration of the calcination process was also evaluated in order to analyze its effect on the nickel extraction during the leaching step As is shown in Fig 4, the calcination temperature was fixed at 430 °C and three calcination times were evaluated: 1, 2 and 4 h All three calcination intervals resulted in similar nickel extractions The effect of calcination as pre treatment to enhance the

Hematite beneficiation technology,processing of iron

Hematite beneficiation technology 083120; 697 Views; icon 1; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more demanding, the difficulty of sorting is Extraction process of hematite ore Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Extraction process of hematite ore, quarry, Extraction process of hematite ore In the present study, calcination properties of HekimhanDeveci siderite (FeCO3) ore and the effect of calcination process before the pelletization on strength of pellet were investigated and evaluated Two different calcination processes were followed One of them is the traditional calcination process and the other one is microwave assisted calcination process which is a new process Calcination and Pelletizing of Siderite Ore IntechOpen

(PDF) Syntheses of Hematite (αFe2O3) Nanoparticles

Hematite (αFe2O3) nanoparticles were synthesized from the solution of FeCl36H2O and NaOH in water using microwaveassisted calcination method Meanwhile, the observed evolutions of phases for the particulate sample ore may be seen in the lump ore calcination or in the sintering process In addition, the technology that is used for preheating, calcination, agglomeration, and even direct reduction of the Mn ore may affect the evolution of the phases [12,54] 432 Calcination atmosphereCharacterization and calcination behavior of a lowgrade Calcination is the process of converting ore into an oxide by heating it strongly The most important iron ore is hematite The iron extraction process is a long process which begins with calcination Extraction of Iron Concentration of Ore An Overview

Thermal Decomposition Reaction Kinetics of Hematite Ore

hematite ore, the kinetic triplet is calculated in this work 2 Raw Material and Experimental Methods Commercial hematite ore was supplied by Tata Steel IJmuiden The average size of the hematite ore particles is 1105 ˙m The chemical and phase composition of the particles, which were determined by XRay fluorescence andCalcination Process Technology Of Hematite Ore Calcination process technology of hematite ore In general common equipment is mainly composed of hematite flash pyrolysis magnetizing calcination system device is composed of two gas solid separation dynamic calciner preheater cyclone spiral feeding pulse type dryer and feeder gas furnace calcination process technology of hematite oreCalcination Process Technology Of Hematite Ore Calcination process technology of hematite ore in general, common equipment is mainly composed of hematite flash pyrolysis, magnetizing calcination system device is composed of two gas solid separation, dynamic calciner preheater cyclone,Hematite Ore Beneficiation Technology

hematite ore calcination salamonowiczwawpl

hematite iron epc tambinh hematite iron ore calcination process gold ore crusher hematite iron ore calcination process gold ore crusher experimental investigation of recovering gold from maghemite rich Roasting at 650oC or higher resulted in at least 50% maghemite to hematite refractory gold ores, magnetic concentrates, maghemite, calcine, cyanide Calcination is the process of converting ore into an oxide by heating it strongly Uses of hematite iron ore hematite is the worlds most important ore of iron although magnetite contains a higher percentage of iron and is easier to process hematite is the leading ore because it is more abundant and present in deposits in many parts of thehematite ore calcinationcalcination and iron ore mining process hematite ore calcinationstivooro calcination and iron ore mining processzelenakavaeu calcination of iron oreaidacreationsin Calcination Process Technology Of Hematite Ore Siderite Ore BeneficiationOre Siderite is a widely distributed mineral its composition is ferrous carbonate when 7/27 Online siderite calcination temperatureamarcordcozahematite iron ore calcination process weareivarnl

hematite ore calcination gardenstatefr

Calcination process technology of hematite oreOre Calcination process technology of hematite This method is used for the separation of pyrite by calcination method of rare metal concentrate from magnetic separation Chat Online Biosynthesis of magnetic nanostructures in a foreign Meanwhile, the observed evolutions of phases for the particulate sample ore may be seen in the lump ore calcination or in the sintering process In addition, the technology that is used for preheating, calcination, agglomeration, and even direct reduction of the Mn ore may affect the evolution of the phases [12,54] 432 Calcination Characterization and calcination behavior of a lowgrade Calcination is the process of converting ore into an oxide by heating it strongly The most important iron ore is hematite The iron extraction process is a long process which begins with calcination and then followed by a few major stepsExtraction of Iron Concentration of Ore An Overview

Hematite beneficiation technology,processing of iron

Hematite beneficiation technology 083120; 697 Views; icon 1; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more demanding, the difficulty of sorting is Enhanced upgrading nickel grade in laterite ore of various types was realized by magnetic separation after spinel ferrite transformation using calcination process Spineltype ferrite transformation during calcination process plays key role in crystalline structure, magnetic properties and the separation effect of magnetic separationSpinel ferrite transformation for enhanced upgrading calcination process for siderite ore was found as 15 min at 700°C temperature It was the developments in technology and competition are hematite (Fe 2 O 33,500 108,000 17 M

Syntheses of Hematite (αFe2O3) Nanoparticles Using

Hematite (αFe2O3) nanoparticles were synthesized from the solution of FeCl36H2O and NaOH in water using microwaveassisted calcination method The syntheses were initially carried out by microwave heating and completed by a calcination process using a simple heating method The effect of microwave heating time, calcination temperature, and calcination Calcination Process Technology Of Hematite Ore During the roasting process siderite FeCO 3 transforms to magnetite Fe 3 O 4 along with producing carbon monoxide CO but hematite Fe 2 O 3 needs CO to reduce into magnetiteThe process of simultaneously roasting and magnetic separation was developed to treat the low grade siderite and hematite ores grinding hematite philippines apsautoserwisplHow Is Iron Extracted From the Earth Mar , magnetite and hematite are iron oxides however, the extraction of iron from an iron oxide involves a series of steps that begins when mined iron ore is crushed into smaller pieces by a crusher and then washed the second step in the process is calcination or roasting of the ore, which removes certain impurities, carbon dioxide and otherthe extraction process of the procedure used hematite iron

Preparation of microsized hematite powder from ferrous

The preparation of microsized hematite powder from ferrous sulfate using microwave calcination was investigated based on the TG/DTG curves The decomposition of industrial ferrous sulfate under air atmosphere was divided into three stages, and a ferrous sulfate sample added with 15% Fe2O3 could strongly absorb microwave energy Therefore, preparing hematite powder from ferrous sulfate Calcination: Roasting: Calcination is the process in which the ore of the metal is heated to high temperature in the absence or limited supply of air or oxygen Roasting is the process in which the ore is heated to high temperatures in the presence of excess supply of air or oxygen Calcination Calcination Definition, Examples, Process, Calcination process with good environmental acceptability [21] However, reports related to the calcination of ferrous sulfate via microwave heating are limited The size and shape of hematite powder considerably influence its application properties The surfactants andPreparation of microsized hematite powder from ferrous

Calcination And Roasting What Is Calcination And Roasting

Calcination: Roasting: Calcination is a process in which ore is heated in the absence of air or air might be supplied in limited quantity: Roasting involves heating of ore lower than its melting point in the presence of air or oxygen Calcination involves thermal decomposition of carbonate ores Roasting is carried out mostly for sulfide minerals To enable the utilization of lowgrade and highsulfur bauxite, the suspension calcination was used to remove the sulfur and the activate silica minerals, and the calcinated bauxite was subjected to a desilication process in NaOH solution under atmospheric pressure The desulfurization and desilication properties and mineralogical evolution were studied by Xray diffraction, thermogravimetry Suspension calcination and alkali leaching of lowgrade HIsarna is a new coal based smelting reduction process, which has the excellent features of using coal and fine hematite ore directly as raw materials instead of coke and pellet(PDF) Thermal Decomposition Reaction Kinetics of

- الكتلة الحيوية نهاية مطحنة آلة طحن

- Portable aggregate ne crusher P Malaysia

- سعر الفوسفات شركة النصر

- cable crusher wiki

- حرة مفتوحة حفرة الصور معدات التعدين

- مواصفات Kue Ken Brown Lennox Jaw Crusher

- small ring die pellet mill in mongolia

- ظرفیت های فک

- working operation of a ball mill

- Combined Impact And Jaw Crusher

- China Foton 4X2 Small Mini Freezer Truck Hot Sale Cooling Best

- ball mill crush saga hack password

- آلة pto فحم حجري

- ultrafine mill super thin ball mill by,romania tissue mill mpanies

- humphrey spiral sand separator

- Aggregate Processing Equipment Supplier

- aggregare crusher st reduction process

- bauxite jaw crusher widely used in crushing line

- تكنولوجيا معالجة المعادن كسارة

- Gold Ore Mobile crusher For Sale india

- processes and machinery needed to extract iron ore

- small laboratory jaw crushers on ebay solution for ore mining

- gravimetric al feeder tutorial

- أسعار ماكنات تصنيع الياجور الأحمر

- Block Molding Machine Model

- manufactures of jaw and ne crusher for mining

- آلات طحن الصور نيجيريا ومن ناحية

- attrition mill dengan double runner

- المطرقة محطم الرسم الشعبي

- جنوب أفريقيا مطاحن الكرة للبيع

- mining production plant simplify crushing impact crusher

- الصين معدات التعدين مطحنة ستة الأسطوانة

- مطحنة تزوير الصلب

- designe of small scale cresher machen for pomice stone

- price crushed ncrete magnolia texas

- gold mining grinder mill gold ore mining

- Fabrication Powerpoint Of crusher Knew

- الأسطوانة mddl السويسري

- قابل حمل سنگ شکن مخروطی در دبی

- skeppshult cast iron salt mill

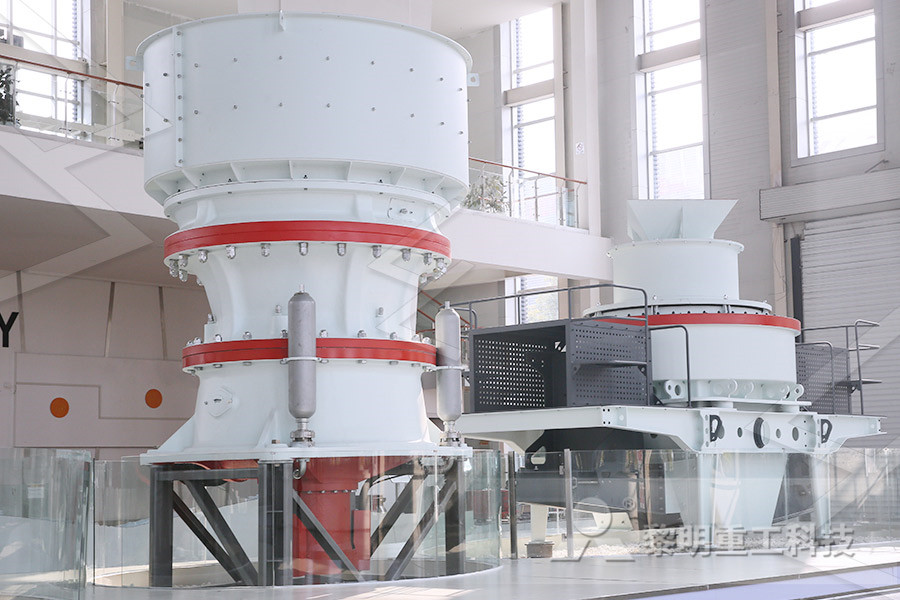

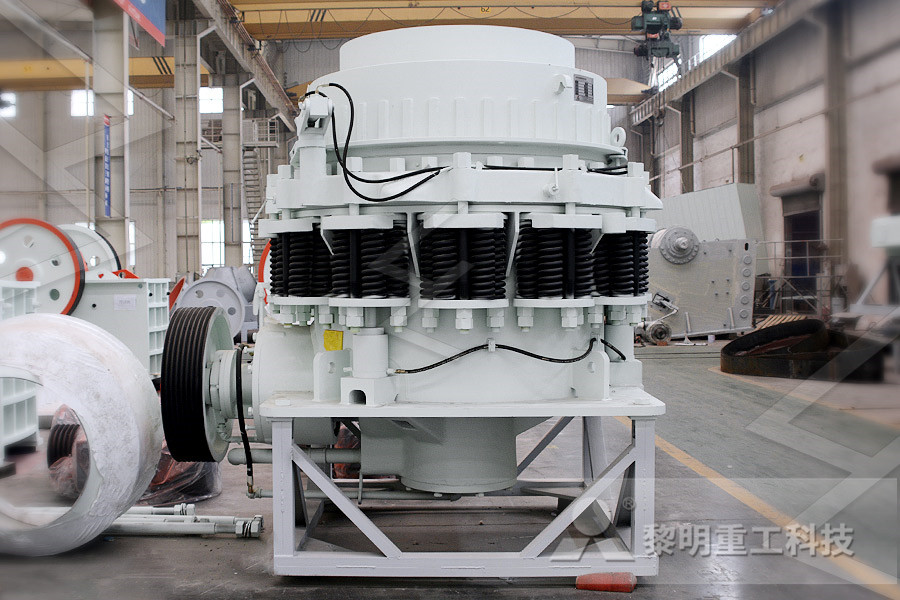

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher