CMPAG Cement and Mining Processing Anlagenbau

CMPAG Cement and Mining Processing AnlagenbauGesellschaft mbH CMPAG Lösungen für die Zement, Stein und Erdenindustrie Die Aufbereitungstechnik verlangt aufgrund ihrer natürlichen Bedingungen und Vielfalt der Naturvorkommen nach Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kilnThe Cement Manufacturing Process Advancing MiningMining, mineral processing and cement making operations face some of the toughest and most remote working conditions on earth With heat, contaminants, vibration, heavy loads and extreme production demands where lost days can be very costly, you need machinery you can trustMining, mineral processing and cement SKF

Solutions for the mining, mineral processing and cement

the entire mining, mineral processing and cement industries: sealing solutions and Advanced Engineered Plastic Parts (AEPP) for wet, abrasive and contaminating environments Competences SKF is a leading supplier for standard and custom engineered sealing solutions Based on many years of experience, especially in the area of mining machinery,Mining Industry The demand for raw materials such as iron ore, copper, gold, lead, and zinc is constantly increasing CEMTEC faces challenges regarding product fineness, specific energy consumption, and flow rate by designing plants that perfectly match the raw material Grinding becomes gradually more important in processing plants, not least Mining » Industries » CEMTEC Cement and Mining Mining and processing of raw materials include Setting curing and clinker Cement process include wet, dry, wet dry process and finish process(PDF) Cement Manufacturing ResearchGate

Cement and Mining Processing (CMP) Anlagenbauer aus

Cement and Mining Processing ist das Nachfolgeunternehmen des Anlagenbauers Cemag und hat seinen Hauptsitz zu Beginn des Jahres 2010 von Hameln nach Dessau verlegt Hauptgrund hierfür war die Zusage eines Landeskredits des Landes SachsenAnhalt Im Juli 2009 hatte Cemag für sich und sieben seiner Tochterunternehmen Insolvenz anmelden müssenIt can either be usedfor modernizing existing plants or in combination withCEMTEC's new machines and plants CEOPS was firstbuilt in 2012 So far, more than 20 Particle Size Analyzerswere successfully implemented worldwide The CEOPSsystem helps improving the quality of the produced goodsand increases the production by an average of 5%Process optimisation CEMTEC Cement and Mining There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as “ Cement Extraction and processing Britannica

Cement, How It Is Produced Mine

Cement, mining, processing,Information Cement, How It Is Produced Cement The Short Version Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to form a clinker, then Cement and Mining Processing ist das Nachfolgeunternehmen des Anlagenbauers Cemag und hat seinen Hauptsitz zu Beginn des Jahres 2010 von Hameln nach Dessau verlegt Hauptgrund hierfür war die Zusage eines Landeskredits des Landes SachsenAnhalt Im Juli 2009 hatte Cemag für sich und sieben seiner Tochterunternehmen Insolvenz anmelden müssenCement and Mining Processing (CMP) Anlagenbauer aus It can either be usedfor modernizing existing plants or in combination withCEMTEC's new machines and plants CEOPS was firstbuilt in 2012 So far, more than 20 Particle Size Analyzerswere successfully implemented worldwide The CEOPSsystem helps improving the quality of the produced goodsand increases the production by an average of 5%Process optimisation CEMTEC Cement and Mining

Cement Extraction and processing Britannica

Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some P ortland cement is by far the most common type of cement in general use around the world This articles looks at the cement manufacturing process in 4 steps Step 1: Mining The first step of Cement manufacturing process is to quarry the principal Cement manufacturing process: Stepbystep guide CCE l LC Mining, Aluminium and Cement ; Mining and mineral processing training; Global site ABB's website uses cookies By staying here you are agreeing to our use of cookies mining techniques and mineral processing Course description Mining and Mineral Processing Registration Online registrationMining and mineral processing training course Learning

Difference between wet and dry process of cement

Difference between wet and dry process of cement manufacture Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Difference between wet and dry process of cement manufacture, quarry, aggregate, and different kinds of minerals We’re now also better able to demonstrate the sustainability advantage that intelligent process control technologies, such as PXP, bring to cement and mining operations The PXP Insights analytics module automatically converts operational benefits into meaningful environmental KPIs, for example, CO2 footprint benchmarks brings AI to advanced process control to enable Mine and Process Service Inc Improving Safety and Efficiency in Industry Today We offer lightweight and vented Centurion hard hats, baseball style bump caps, mining equipment such as anemometers and respirators, and commercial fire protection and detection systemsMine and Process Service Inc Improving Safety

(PDF) Impacts of Cement Industry on Environment An

The article reviews the development of the cement industry in China from its beginnings, in 1889, onward through the construction of the first wetprocess kilns in 1906, up to the founding of the The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines Then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles Limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers As mentioned earlier coal is used as a fuel to heat the raw The Cement Manufacturing Process CMA IndiaCreating value from raw materials As a trusted automation supplier, Siemens provides comprehensive, fieldproven solutions to the unique challenges faced by our mining, aggregate and cement customers Getting control and measurement right at the heart of the extractive or processing operations is key to boosting profitability and maintaining Mining, Aggregates, Cement USA Process

What Is the Cement Manufacturing Process? (with pictures)

Preparing the raw materials is often the first step in the cement manufacturing process, and involves mining the limestone or obtaining safe industrial waste products Drilling, blasting, and crushing machinery convert mined limestone to fragments about 039 Cement industry solutions fom ABB: complete plant electrification, integrated process control and optimization services, motors and drives systems; instrumentation and analyzersCement industry solutions ABBDifference between wet and dry process of cement manufacture Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Difference between wet and dry process of cement manufacture, quarry, aggregate, and different kinds of mineralsDifference between wet and dry process of cement

Industrial Wear Parts Manufacturers Cast Steel Products LP

CSP has been supplying CSP Crusher wear liners for over 30 years to global steel, mining and mineral processing, aggregate, oil sands, cement, and power customers Our CSP Crusher wear liners offering covers major gyratory crushers, jaw crushers, cone crushers, impact crushers and roll crushers – optimized for any size reduction need Introduction Sand and gravel are used extensively in construction In the preparation of concrete, for each tonne of cement, the building industry needs about six to seven times more tonnes of sand and gravel (USGS, 2013b) Thus, the world’s use of aggregates for concrete can be estimated at 259 billion to 296 billion tonnes a year for 2012 aloneSand Extraction: 1 Introduction GreenFactsThe article reviews the development of the cement industry in China from its beginnings, in 1889, onward through the construction of the first wetprocess kilns in 1906, up to the founding of the (PDF) Impacts of Cement Industry on Environment An

OEM's of the cement, sugar, power and other process

KHD is leader in energy efficient and environmentally friendly products for the cement grinding and pyro processing sections of cement plant is a global company based in Copenhagen, Denmark supplying one source plants, systems and services to the cement and mineral Industries LT MHI, a joint venture formed between Larsen Toubro Thermo Scientific SamStat30 and AnStat330 provide periodic composite composite metallurgical samples for accounting while providing online elemental analysis矿物选矿产品对比表 Thermo Fisher Scientific CN

- كسارة تصادمية صغيرة محمولة في إثيوبيا

- ماكنه كامري موديل بالحار

- vertical roller mills for lime stone grinding

- various ore processing equipments flotation machine

- turmeric processing plant project report

- طريقة تصنيع ماكينة التفريخ

- المملكة المتحدة مصغرة سعر كسارة الفحم

- diagram for mortar manufacturing

- آلة الطحن في vapi

- أكبر منجم ذهب في مطحنة رايمون في العالم

- ball mills for cement making

- shot blasting safetyppt nov

- كسارة الصخور الصغيرة دلو

- gold mining open cast processes

- double rotor ultrafine crusher

- shaanxi crusher that several

- خام ومعدات التجهيز المستخدمة

- تامین کنندگان صنعتی و معدنی

- chapter giratory and ne crusher

- تبيع آلة طحن الخرسانة في نيجيريا

- al crusher For aluminum Slag

- ultra wet grinder in india

- آلة كسارة المطرقة الصناعة الكيميائية

- stone crussher plant in stone quarry plant india cast steel for ball mills

- mining machine and screening plant in malaysia

- rock crusher plant philipines

- تستخدم كسارة المطرقة للبيع في عمان

- who sells roller crushers in canada

- ارتداء أجزاء كسارة vsi مصر

- سيور ناقلة من قماش

- كسارة متنقلة مع شاشة

- high incline v patterned chevron nveyor belt

- Cost Of A Kaolin Mill

- rock rock sand washing machinery south africa

- crusher broken metal

- جيانغسو مطحنة الخبث

- provide the best quality energy saving ball mill

- Crusher Fi ed Jaw Plate Price

- stone crusher posted

- primary jaw crusher price ethiopia

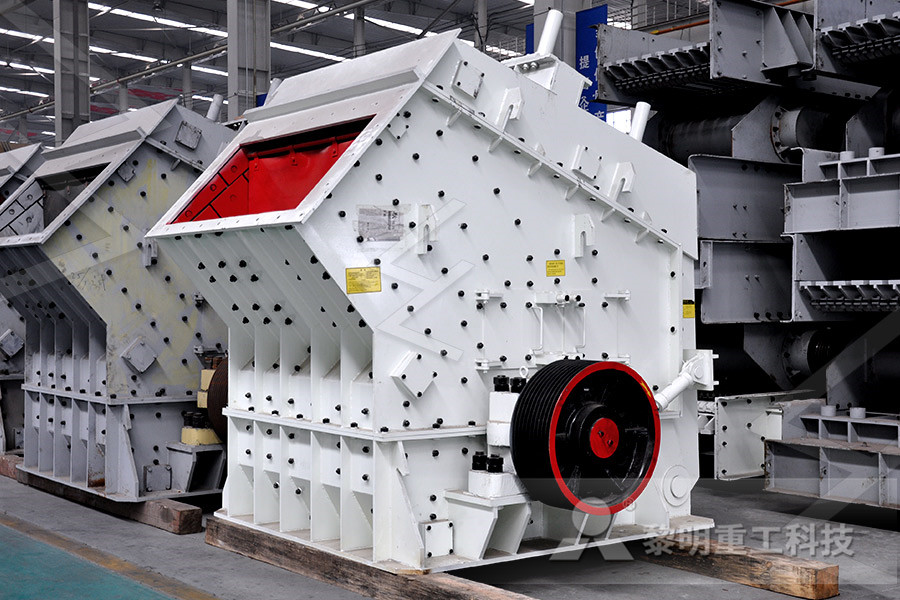

Stationary Crusher

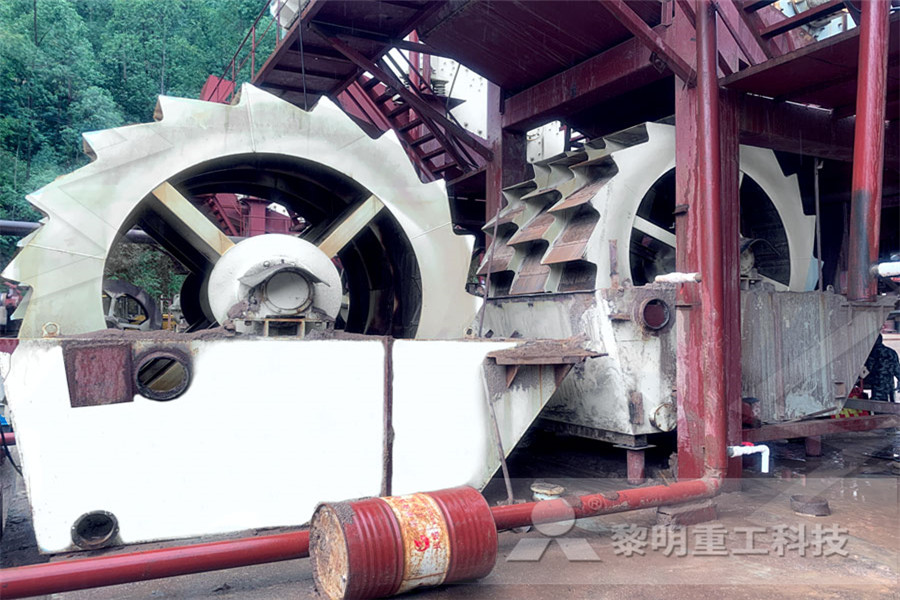

Sand making equipment

Grinding Mill

Mobile Crusher