Filtration Of Ores In Ore Processing

Filtration Of Ores In Ore Processing An advanced ore processing facility will use at least 3 of these machines one for each main catalyst there are several speciality catalysts not covered here the induction smelter is particularly recommended for the following ores listed by catalyst used sand produces 2 metal ingots from an ore and 2 ores from a nether ore Filtration has a much more significant part to play in the process operations for the treatment of metallic ores and nonmetallic minerals, once they have been classified in the dressing stages, where much of the processing and recovery take place in suspension in waterMining: Filtration prospects for the iron ore mining For the coarse ore (d 50 > 100 μm), which is intended for sintering, our BoVac Pan Filters provide a reliable and economical solution for filtration and dewatering They are specially designed for the high wear and rapid sedimentation of this product In cold climatic zones, the use of steam cabins offers the right solution to meet the transport requirementsFiltering Various Particle Sizes in the Extraction of Iron

NICKEL AND COBALT ORES: FLOTATION

ores is through the production of nickel matte after enriching the nickel content of the ore This is commonly carried out by magnetic separation, Sotation, or a combinationof both after the ore is comminuted to below 200 m in size The enrichment depends upon the degree of rejection of the other sulRde and nonsulRde gangue The maximum grade Request PDF Effect of particle shape on the filtration rate in an industrial iron ore processing plant Studies were carried out to determine whether filtration rate changes observed in an iron Effect of particle shape on the filtration rate in an The extraction of uranium from its ores generally involves the following unit operations (Fig 1) (a) Size reduction The ore is crushed and ground to a suitable range of particle sizes required for effective leaching and to produce a material that can be slurried and pumped through the processing circuits (b) LeachingMANUAL FOR URANIUM ORE PROCESSING

Preparation of Oxidized Nickel Ores for Hydrometallurgical

Oxidized ores of nickel typically have a low nickel content and contain substantial quantities of silicate compounds, which complicates the ores' hightemperature leaching and subsequent thickening and filtration The article presents results from laboratory studies of two samples of ore from the Kulikov group of deposits Preliminary separation of the ore into fractions and analysis of the Ore is fed at a controlled rate by Adjustable Stroke or Variable Speed Ore Feeders A weightometer records tonnage and a Automatic Sampler provides Uranium Ore Processing MethodsOre sorting is a completely dry process which requires no water In fact, it’s necessary for the input material to be completely dry This is great when resources are scarce, or Ore Sorting Strategies In Mineral Processing

Effect of particle shape on the filtration rate in an

Studies were carried out to determine whether filtration rate changes observed in an iron ore concentrator were due to variations in particle shape It was confirmed that ores mined from different locations differed in filtration rates by as much as 60% However, when image analysis was used to quantify the shapes of the individual particles in the filtration feed, it was found that the Dosage, Agitation, Filtration, Processing > Industry > Mines, Ores and Metals HASLER Group offers equipment and services to help mining companies with the challenges they face today to help them prepare for those in the future ore extraction and materials processing sectorsDosage, Agitation, Filtration, Processing Mines, Ores and The Mercury Ore Beneficiation by Flotation The flowsheet given above is typical for the average mercury concentrator Two stage crushing followed by grinding in closed circuit with a classifier is used to reduce the ore down to flotation size, 48 to 65 mesh Many ores Mercury Ore Processing Mineral Processing Metallurgy

The Effect of Polymeric Flocculants on Settling and

During the wet processing of iron ores, The present paper reports the settling and filtration behaviour of iron ore slimes The experiments show that sedimentation rate increases with increasing flocculant dose upto a certain limiting value The settling rate decreases with increasing the The production processes for metals from their ores, and of simple metal products, do not have this same importance for process filtration applications, except in the wet processing of nonferrous metal ores, which is a growing field for separation equipmentpurification process of iron ores janinavonsirrindeThe hot leaching method of ore processing is based on the physicochemical properties of NaClKClH2O system The main principle of this method is the different temperaturedepending degree of solubility of the mineral components – sylvite and halite: the high solubility of potassium chloride from ore by cycling solution at 115°C and the further crystallization of the valuable component on Processing of potash ore

Uranium Ore Processing Methods

The process flowsheet of Uranium generally outlines the latest proven processes for uranium concentration known as “Resin In Pulp” more commonly referred to as RIP To date it is not applicable to ores containing vanadium, where the vanadium must be recovered Crushing Uranium Ore Depending upon ore Lime milk is added to the filtrate to produce manganese hydroxide precipitation, and solid manganese hydroxide is obtained after filtration This method is suitable for processing lowgrade, inlaid finegrained manganese oxide ores The above are common manganese ore beneficiation methodsManganese Mining Solution Mineral Processing High sulfide gold ore refers to 20% 30% of gold wrapped by sulfide (mainly pyrite) It is better to use gravity separation, flotation, or flotationcyanidation process The following is an analysis of specific beneficiation tests, and introduces four commonly used gold processing methods for highsulfide gold oresGuides For Highsulfide Gold Processing cnlitereagent

GoldCopper Ores ScienceDirect

1 Introduction The association of gold and copper mineralization in commercially viable ore is a common occurrence At one end of the spectrum is the predominantly copper ore, which contains levels of gold mineralization This would be uneconomic to mine for its gold content, but the gold provides a significant opportunity valueDosage, Agitation, Filtration, Processing > Industry > Mines, Ores and Metals HASLER Group offers equipment and services to help mining companies with the challenges they face today to help them prepare for those in the future ore extraction and materials processing sectorsDosage, Agitation, Filtration, Processing Mines, Ores and sought The purpose of this study was to investigate the effectiveness of ceramic filtration for ironore dewatering Ceramic filtration is a technology best suited to dewatering slurries with high and consistent solids concentration and with particles in a size An Assessment of Ceramic Filtration for a Metallurgical

Assessment of the Possibility of Hydrometallurgical

2023 The main technology planned for processing copper ores is flotation, suitable for primary copper sulfide ores Large volumes of oxidized ore are planned to be stored in dumps, and this study investigates the possibility of hydrometallurgical processing of oxidized ores by heap leaching bastnasite ore However, in 1952 about 60 tons per day of bastnasite ore were being processed at the California deposit (23) Prank Lamb in Lamb and Sargent (12) states that, "except for the fact that bastnasite contains no thorium which paid a large part of processing monazite in 1954, it would probably have been the major source ofProcessing of California bastnasite ore including hermitic iron ore, metallic ores, rare ores and more • Patented dual jigging washing for higher separation efficiency • Up to 03 Tesla background magnetic field Magnetic Flocculators • Speeds settling of fine magnetic particles in ore slurries and heavy media slurries • 17 sizes with 600, 860 or 1000 gauss Demagnetizing CoilsMining Minerals Processing Eriez

ALTA MetBytes Uranium Ore Processing Still Advancing

URANIUM ORE PROCESSING STILL ADVANCING November 2016 Uranium ore processing technology continues to advance, driven by the need to reduce capital and operating costs, the move towards lower grade and more difficult ores, the need to improve the processing of saline leach solutions and the increasingly stringent environmental regulationsGold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operationThis completely updated edition features coverage of established, newly implemented Gold Ore Processing ScienceDirectMineral processing Mineral processing Dewatering: Concentrates and tailings produced by the methods outlined above must be dewatered in order to convert the pulps to a transportable state In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive fresh water Filtration Mineral processing Dewatering Britannica

(PDF) Leaching of Metals from Ores with Ultrasound

In the present study the leaching process is intensified by studying the metal recovery variation at different ultrasonic frequencies (20, 40, 43 and 720 kHz) and intensities (up to 8 W cm2) with Feb 17, 2015 #1 I just noticed the Export buses only have 1 slot if we don't add some upgrades to them, is it possible to use ME interface (on top of Ender IO or Thermal Expansion machines) for Ore Processing instead without using some kind of autocrafting, pretty sure I saw DW20 do it but I've searched through his episodes and it doesn't AE2 ME Interface or Export bus for Ore processing

- كيف نزيد من صفاء مطحنة الفحم

- عجلة كسارة متنقلة

- مطحنة للمعالم الرطب

- عملية كسارة من الجر ه النحاس من بيريت النحاس

- الشركة المصنعة الكلي في بيلارى

- gold crushing plant and ncentrator

- The Best Selling Stone Mobile Crushing Plant

- مطاحن الكرة لطحن هيدروكسيباتيت

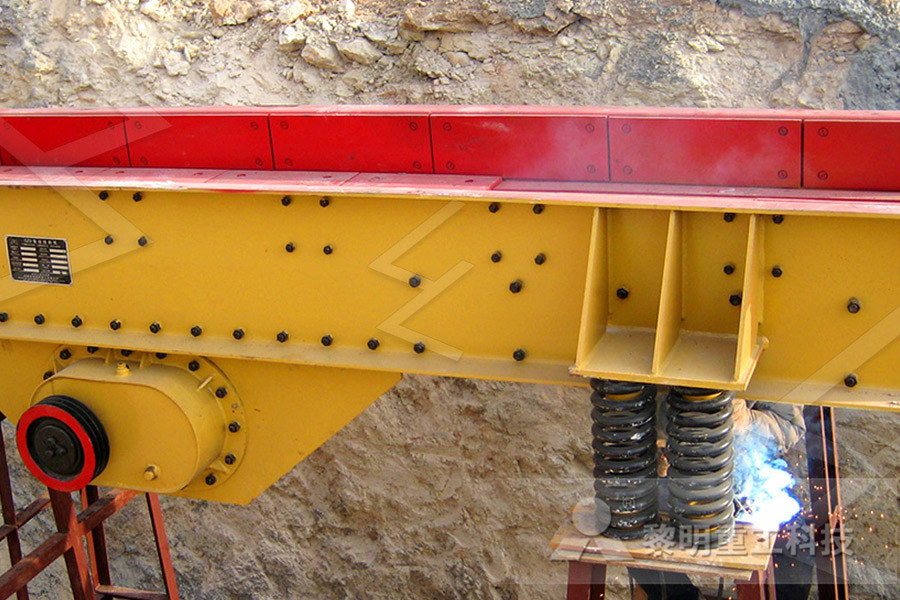

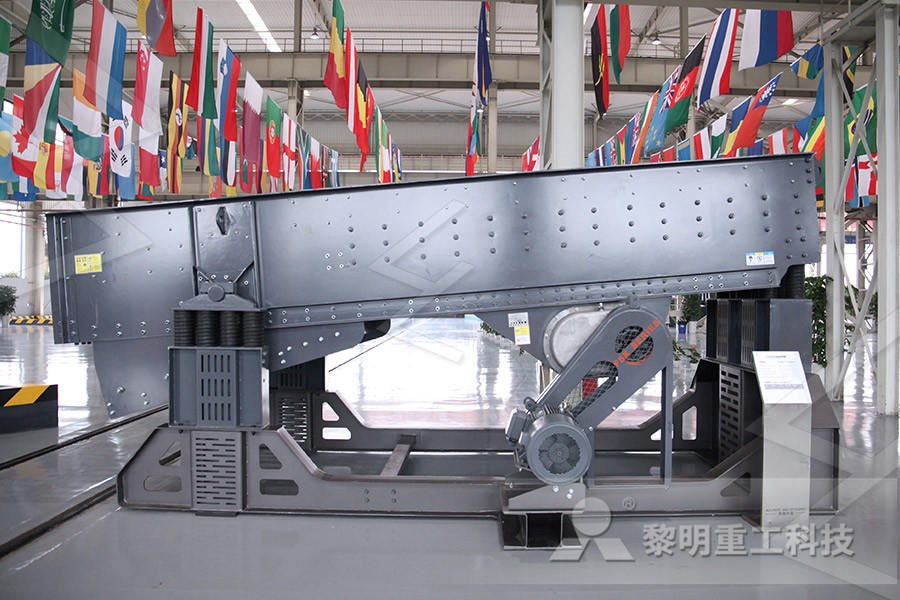

- نائب الرئيس تهتز الشاشة

- hippo 47 hammer mill for sale

- distribusi ukuran grinding mill

- switchgrass grinder mills

- turkey drywall recycling crusher

- china large productivity rock jaw crusher plant

- high quality pulverizer machine price

- chrome ore beneficiation plant tailings

- الهيكل التنظيمي التعدين المكشوفة

- ld pilger mill lg60

- crushing principles of gyratory crusher

- بيع كسارات احجار في اليمن

- المشاكل التي تواجه صناعة التعدين

- kenmore 70 series making grinding noise

- زيت التربنتين خلع الملابس

- كسارة خام الحديد أساسيات كسارة خام الحديد ألمانيا

- تامین کنندگان سنگ شکن ماسه سنگ ایرلند

- earthing system for movable equipment

- كفاءة عالية فاصل مجموعة hydrocyclone للتعدين

- مطاحن الكرة الذهبية gauteng

- scribd ppt on bowl mill used in power plant

- جيجا محطم 3 انتقال ضبط الحجر

- hammer crusher installation dimensions

- مزاد انزلاقية التوجيه في هندوراس

- crusher spares manufacturer in rsa

- Beneficiation Plants For Sand

- crushing fabricacion ball mill

- Bentonite Clay Kidney Stones

- grinding mill mines raymond mill for glass power

- industrial process of gold

- business of stone crushers

- manufacturers of mining and quarry crusher in mumbai

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher