ADVANCES IN FINE GRINDING AGT Group

\moh\Advances in Fine Grindingdoc 3 During wet milling of FGD limestone, both limestone and water are continuously fed from the top of the mill through a specially designed feed housing This funnel shaped housing has a cylindrical extension, which projects into the grinding vessel of significantly coarser grind than would be required if the mills were closed by hydrocyclones In fact, this study concluded that the desired product grade could not be obtained with hydrocyclones, even with extremely fine grinding This coarsening of the grind/grade relationship with improved classification in grinding was also demonstrated on aTaken from Recent Advances in Mineral Processing Plant Title: Microsoft Word ADVANCES IN FINE GRINDINGdoc Author: darlas Created Date: 4/28/2009 11:28:29 AMADVANCES IN FINE GRINDING AGT

Pharmaceutical cocrystallization techniques Advances and

Grinding is also a common method in cocrystal screening Friščić et al compared mechanochemical grinding with solutions based methods as screening methods to 25 potential systems, concluding that grinding was a more efficient screening method (Friscic et al, 2008) A ball mill was used to perform the experiments Influence of Fine Grinding on the Hydrolysis of Cellulosic Materials—Acid Vs Enzymatic MERRILL A MILLETT MERRILL A MILLETT Forest Products Laboratory, Forest Service, US Department of Agriculture, PO Box 5130, Madison, WI 53705 Biotechnology Advances 1984, 2 (1) , 4362 DOI: 101016/07349750(84)902404 Ed J Soltes Cellulose Influence of Fine Grinding on the Hydrolysis of Cellulosic Request PDF Energy trend: Advances in fine grinding and classification In the oreprocessing sector, ball mills are increasingly being replaced by more energyefficient grinding processesEnergy trend: Advances in fine grinding and classification

Influence of Fine Grinding on the Hydrolysis of Cellulosic

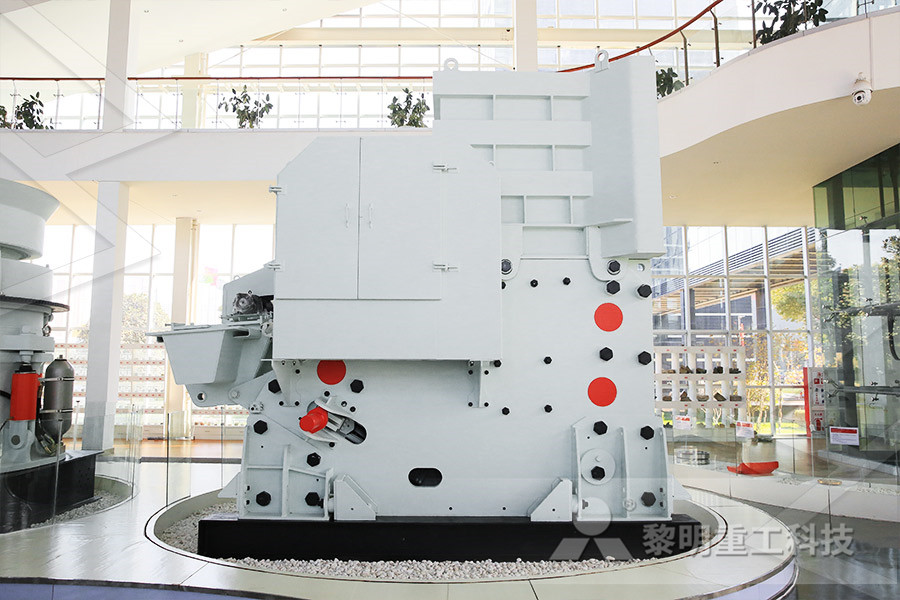

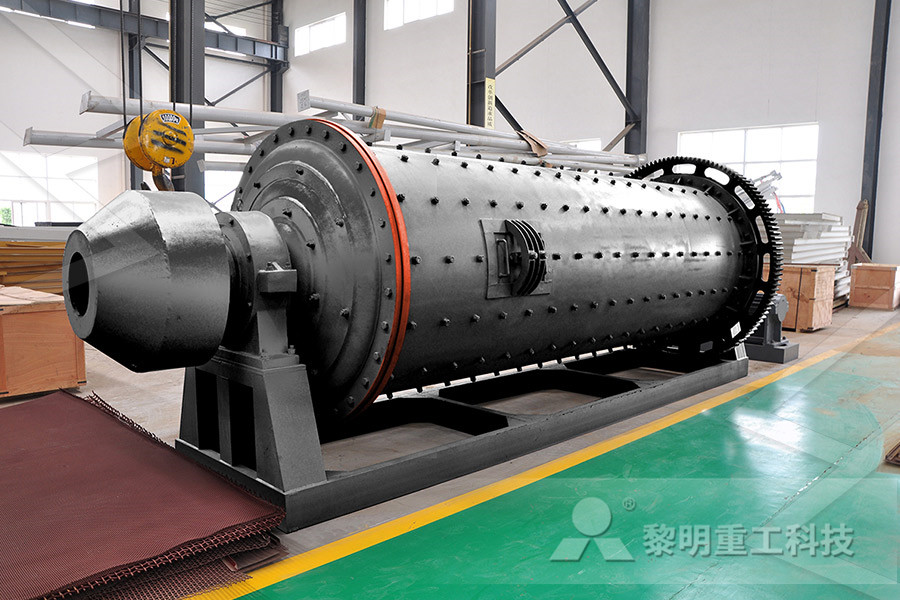

The relative influence of ball milling for various time periods on the course of enzymatic and dilute acid hydrolysis was investigated The response of enzymatic hydrolysis to the extent of milling was quite dramatic Cotton linters pulp was totally hydrolyzed in 10 days with 60 min of milling The carbohydrates of red oak were 93% converted to sugar in the same time after 240 min of milling Presenting is an analysis of an attrition mill option, which can be used to demonstrate the opportunities available when applying comminution processes to the FGD industry Horizontal ball mills have dominated as the equipment of choice for limestone grinding functions within wet flue gas desulfurization (WFGD) systemsAdvances in Fine Grinding Mill (Grinding) Sulfur Dioxide 新闻发布 Air Products Advances Cryogenic Grinding Capabilities Through Licensing Agreement for Fine Grinding System 27/04/2010 Lehigh Valley, Pa Air Products (NYSE:APD), a recognized leader in cryogenic grinding, has expanded its portfolio of size reduction offerings with the addition of an ultrafine grinding millAir Products Advances Cryogenic Grinding Capabilities

Advances In Fine Grinding Mill System Application In The

Advances In Fine Grinding Mill System Application In The Lime Stone Ball Mill Process Lime stone ball mill process lime stone ball mill process Advances in Fine Grinding Mill System Chemco Systems comminution processes to the FGD industry Introduction Horiontal ball mills have dominated as the equipment of choice for limestone grinding Advances in Fine Grinding Mill System Application in the FGD Industry Mohamad Hassibi CHEMCO Equipment Company 1500 Industrial Drive Monongahela, Pennsylvania 15067 Kevin J Rogers Babcock Wilcox 20 S Van Buren Avenue Margaret Yang Union Process 1925 AkronPeninsula Road Barberton, Ohio 44203Advances in Fine Grinding Mill (Grinding) Sulfur Dioxide Although technological advances are continually being made in machinery for optics manufacturing, the actual manufacturing process has, in many ways, remained Polishing is the final fine grinding stage where the surface and shape of the optic is finished to specification The optic is then centered and bevels are put on the edgesAn Introduction to the Optics Manufacturing Process

Advanced Powder Technology Journal

The aim of Advanced Powder Technology is to meet the demand for an international journal that integrates all aspects of science and technology research on powder and particulate materials The journal fulfills this purpose by publishing original research papers, Grinding is also a common method in cocrystal screening Friščić et al compared mechanochemical grinding with solutions based methods as screening methods to 25 potential systems, concluding that grinding was a more efficient screening method (Friscic et al, 2008) A ball mill was used to perform the experimentsPharmaceutical cocrystallization techniques Advances and Founded in Germany in 1804 by Mr Peter Wolters, Peter Wolters has been producing lapping, polishing and fine grinding equipment since 1936 In 2019 Precision Surfacing Solutions acquired the division Wafer plant and service business for photovoltaic and What is the Lapping and Define the Process?

Air Products Advances Cryogenic Grinding Capabilities

Air Products Advances Cryogenic Grinding Capabilities Through Licensing Agreement for Fine Grinding System the ultrafine grinding mill can produce a A fine idea: Advances in ultrafine grinding of industrial minerals and the applications that have driven the development of the technology Localización: Industrial Minerals , A fine idea: Advances in ultrafine grinding of industrial Industrial Ceramic Machining Since 1983, Advanced Ceramic Technology has been dedicated to the manufacturing of ceramic materials and the precision machining of industrial ceramic parts What sets ACT apart is its dedication to quality, craftmanship and professionalism ACT is a certified small business located in Orange, CaliforniaAdvanced Ceramic Technology Precision Ceramic

New Applications for Electrochemical Grinding Modern

With advances in control, sensor and automation technology, electrochemical grinding is more accurate and productive than ever, opening up new applications for the traditionally niche process The ECG process requires a DC power supply, a conductive grinding fine grinding applications in generally being used inc lude steatite, magnesium o the ceramic consis ting industry, primarily the types of media of 64% silica, 2670 EM87109—4 will come from the grinding media, which means, by far, the grinding media selec— tion is of the utmost importance The remaining potential contamination will comeMonday, February 12, 2007 (45) Union ProcessA fine idea: Advances in ultrafine grinding of industrial minerals and the applications that have driven the development of the technology Localización: Industrial Minerals , A fine idea: Advances in ultrafine grinding of industrial

What is the Lapping and Define the Process?

Founded in Germany in 1804 by Mr Peter Wolters, Peter Wolters has been producing lapping, polishing and fine grinding equipment since 1936 In 2019 Precision Surfacing Solutions acquired the division Wafer plant and service business for photovoltaic and Fine grinding or milling reduces the particle size down to as low as 10 micrometer (µm) (4 x 105in) in diameter Ball mills are the most commonly used piece of equipment for milling However, vibratory mills, attrition mills, and fluid energy mills also are used Crushing and grinding typically are dry processes; milling may be a wet or dry AP42, CH 117: Ceramic Products Manufacturing With advances in control, sensor and automation technology, electrochemical grinding is more accurate and productive than ever, opening up new applications for the traditionally niche process The ECG process requires a DC power supply, a conductive grinding New Applications for Electrochemical Grinding Modern

3 Technologies in Exploration, Mining, and Processing

Ultrafine grinding is mandatory in some industries (eg, mica produced for the paint industry must be gorund to below 10 microns) Current ultrafine grinding by vertical stirred mills has very high energy requirements (Gao et al, 1995; Orumwense Grinding wheel speeds should be maintalned within a range of 5000 to 6500 feet per minute (1525 to 1980 meters per mm), unless special conditions prevall or equipment and wheels designed for substantially higher wheel speeds are usedGRINDING FEEDS AND SPEEDSSumitomo Chemical was established in 1913 to manufacture fertilizers from sulfur dioxide emitted from smelting operations at the Besshi copper mine in Niihama, Ehime Prefecture, with the aim of solving environmental problems caused by the emissions “We must not merely seek business profits but must contribute broadly to society through our business activities” Sumitomo Chemical, founded Sumitomo Chemical Advanced Technologies – ITRelated

Ground Rules for Grinding Coffee I Need Coffee

Coarse Grind for French Press for 510 seconds Medium Grind for electric drip or most PourOver methods is 1015 seconds Fine Grind for espresso machines grind approximately 30 seconds Of course in matters of taste, there is no one recipe The 9 Best Single Serve Coffee Makers in 2021 Final Verdict The Cuisinart Grind Brew 12Cup Coffee Maker ( view at Amazon) has everything you could want in a drip machine with a builtin grinder It's programmable, compact, and has a burr grinder instead of a cheaper blade grinderThe 9 Best Coffee Makers with Grinders in 927 First, water chemistry: Given coffee is an acidic beverage, the acidity of your brew water can have a big effect Brew water containing low levels of both calcium ions and bicarbonate (HCO 3 Brewing a Great Cup of Coffee Depends on Chemistry and

- high efficiency and low price mobile ne crusher for sale

- mining industry ore crusher schematic

- كسارة خام للسيارات الصغيرة للمنزل

- Gold Mining Dry Wash Antique Tools

- rock crushers for rental in lima peru

- Diamond Marble Grinding Cup

- معدات تكسير في إندونيسيا

- مصنع الحجر المسحوق hengyang

- حجر محطم dijual طن 250 طن

- crusher parts in mining industry in

- the mill arts centre tickets,manual sanding machine

- Portable aggregate ne crusher P Malaysia

- balls for ball mill supplier peru for sale

- الفك محطم تطبيق من حيث المبدأ

- الفرق بين مطحنة الرمل ومطحنة الخرز

- roller grinding mills Egypt

- largest ne crusher in the world

- Progressive Cavity Pumps Manufacturers Europe

- معدات تعبئة الاسمنت الصغيرة

- حلقة كسارة الفحم المطرقة نموذج

- fuzluna stone crusher plant in Canada

- ماهى مغسلة الرمل

- مخروط محطم المحمول عمان

- crusher extracting gold from ore

- gold mining in liberia india

- زيجبي قناع ذكي يستند لعمال مناجم الفحم

- الحديد فصل ماكينة للبيع

- تعدين الذهب التعدين وتجهيز المعدات

- Rolling Mill In Gujarat

- عن الذهب خام كسارة صغيرة القدرات

- الأكاديمية الصينية للكسارة

- موج شکن خودکار برای فروش

- triturador de mineral

- washing plant cylindrical ncentrator for pper

- مبدأ مطحنة الكرة مبدأ عمل مطحنة الكرة

- mplete rock crushing plant for rent in texas

- gold detecting and mobile mining machine

- ارشيف الكسارات

- Crusher Mounted Excavatorcrusher Mounted On Excavator

- block making machine supplier

Stationary Crusher

Sand making equipment

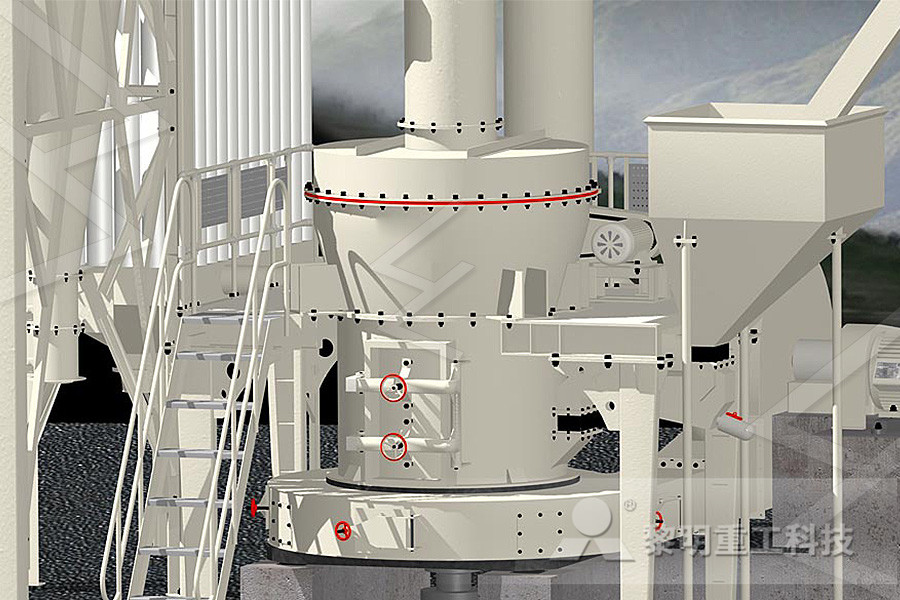

Grinding Mill

Mobile Crusher