ball attrition grinding – Grinding Mill China

ball attrition grinding [ 49 7933 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products ball attrition grinding – Grinding Mill China Grinding media steel balls, hardened steel media, 2 to 12 mm Grinding Media Steel Balls: Steel forged grinding media,attrition mill,grinder,ball mill suppliers YouTube,Jul 08, 2015 Fast Extreme Automatic Steel Balls Manufacturing Process,,Attrition Milling at Hosokawa Micron Powder Systems Duration:,Coal Grinding Process,ATTRITORS AND balls grinding attrition strefaklientapl The attrition grinding machine used was a 5inchdiameter unit, originally developed by Bureau personnel (6, 10) as a scrubbing device for beneficiating glass Attrition Grinding Mill Design

Effects of impact and attrition mechanisms on size

Within the scope, the first phase of grinding tests consisted of ball milling and stirred milling of calcite within a single and multicomponent environment For the mixtures, each component was separated via chemical analyses hence comparisons were made regarding to Attrition Mill; A tabletop W is the work index measured in a laboratory ball mill and can be used after ball mills in a grinding process Like ball » Learn More ball mining process of attrition; sample of attrition scrubbing process used attrition scrubber sand Mining attrition scrubber used in iron ore » Learn More I would love to Ball Mining Process Of Attrition – Grinding Mill China Media sizes for coarse grinding in heavyduty ball mills range from about 80 mm maximum to 20 mm and for medium to fine grinding mill on down at about a minimum of 8 mm Below about 16 mm, removal of the ground mixture becomes increasingly Attrition Grinding Mill 911 Metallurgist

attrition of ball mill wagabundzipl

Attrition Grinding Mill Design 911 Metallurgist Jun 09, 2017 the attrition mill and in ball, planetary, and vibration mills A considerably higher rate of size reduction was achieved in the attrition mill compared with the other three mills The data show that 01micrometerdiameter particles were produced in 2 hours with attrition milling, 10 hours with planetary milling, and 30 hours with A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect TopicsUsing Ball Mills to Extract Raw Gold from Ores Jun 14, #; Many early mines used stamp mills, but many operations today find that ball mills are more functional for smaller operations and perform well with the modern equipment we have available now such as combustion engin The Function of a Ball Mill To perform its functions, the ball mill operates on the principle of impact and attritionball mill attrition impact mill peru

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

A series of batch grinding tests were carried out using three loads of single size media, ie 306 mm, 388 mm, and 492 mm Then two ball mixtures were successively considered The equilibrium ball mixture was used to investigate the effect of ball size distribution on attrition grinders wet ball mill Continuous Attritors are best suited for the continuous production and fast grinding of large quantities of material They are designed to deliver hours of lowcost maintenancefree operation The basic model features a system that does not require an expensive shaft sealattrition grinders wet ball mill greenportfashionAttrition Grinding Process Attrition ball mining process of attrition grinding mill china get now jaw crushers and hammer mills for ore mining mbmmllc the hammer mill takes the 34 discharge from the jaw crusher and pulverizes it to liberate the values in the ore usually gold and is a component of our get now disc attrition mill animation youtubeBall MillAttrition Grinding Mill eaannemersbe

Stirred Ball Attrition Mill CHERIC

stirredball attrition mill Abstract −To develop a highperformance structured catalyst, the fine grinding characteristics of alumina was investigated by a stirredball attrition mill The grinding kinetics approach was successfully applied to the analysis of particle size distributions obtained under various grinding timesball ball mining process of attrition in morocco ball mining process of attrition attrition grinding process grinding process attrition ies2017org Jun 22 2017 attrition mill in gold mining attrition ball mining hometbmueblerias A ball mill is a type of grinder used to grind materials like into extremely fine powder for use in A large number of SAG Mills are supplied to the mining industry of ball mining process of attrition pucharpomorzaplattrition mill pH stirredball attrition mill Abstract To develop a highperformance structured catalyst the fine grinding characteristics of alumina was investigated by a stirredball attrition mill The grinding kinetics approach was successfully applied to the analysis of particleAttrition Of Ball Mill orchesterwerkede

Attrition Mill Grindingball Mill tischlereikaulichde

Attrition And Grinding Mill Popular Education, The dry finegrinding attrition mill consists of a stationary cylindrical vertical grinding chamber as read more grinding mills holdtrade uk ltd website Attrition Mill Grinding Sep 13 2010 there are many different types of grinding mills table 1 some devices such as ball mills are more suitable Ball Mill Grinder Attrition Mill thomasstroeckensde A ball mill is a form of grinder that is used to blend or grind materials for use it is a cylindrical device mainly for grinding material such as iron ores, ceramic raw materials, glass, steel, etc the ball mill works on impact and attrition principlemachine attrition ball grinding MC World Attrition Grinder The batch grinding tests were made in the Bureau’s 10inchdiameter attrition grinder, which is described in detail in an earlier report The unit, as assembled for batch testing, is shown in figure 1 The grinder consists of a rotor and Attrition Grinding Mill 911 Metallurgist

Effects of impact and attrition mechanisms on size

Studies related to multicomponent grinding is not limited to ball milling Compression milling technology was considered by Abouzeid and Fuerstenau The research had drawn similar conclusions to that of ball milling where the grinding results were found to be influenced by proportions of the mineralsball mill grinding theory akustycznepl Hammer mill attrition rubbing actiondifferences between attrition mills and hammer millssome of these include attrition mills ball mills and hammer mills get price sand project report and copper processing and hammer mill crusher jun 11 2014 ball mill china ball is the material to be broken and then to smash the is different to adjust the gap grinding ball mill attrition rubbing actionBalls Grinding Attrition An Efficient, LongerLasting Virtually ContaminationFree Solution for Ceramic Grinding Milling Zirconia YSZ grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materialsBalls Grinding Attrition refedu

Stirred Ball Attrition Mill CHERIC

stirredball attrition mill Abstract −To develop a highperformance structured catalyst, the fine grinding characteristics of alumina was investigated by a stirredball attrition mill The grinding kinetics approach was successfully applied to the analysis of particle size distributions obtained under various grinding timesball ball mining process of attrition in morocco ball mining process of attrition attrition grinding process grinding process attrition ies2017org Jun 22 2017 attrition mill in gold mining attrition ball mining hometbmueblerias A ball mill is a type of grinder used to grind materials like into extremely fine powder for use in A large number of SAG Mills are supplied to the mining industry of ball mining process of attrition pucharpomorzaplattrition mill pH stirredball attrition mill Abstract To develop a highperformance structured catalyst the fine grinding characteristics of alumina was investigated by a stirredball attrition mill The grinding kinetics approach was successfully applied to the analysis of particleAttrition Of Ball Mill orchesterwerkede

Effects of impact and attrition mechanisms on size

Studies related to multicomponent grinding is not limited to ball milling Compression milling technology was considered by Abouzeid and Fuerstenau The research had drawn similar conclusions to that of ball milling where the grinding results were found to be influenced by proportions of the mineralsAttrition Grinding Millingmining Machine Ball mill wikipediaA ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering it works on the principle of impact and attrition size reduction is done by impact as Chat OnlineWhat Impact And Attrition In Ball Mill skimilldeAttrition Of Ball Mill Ball mill attrition mill mills attrition mill alpine the mill choose the right grinding mill union process table 1 the size of the media affects the end result of the milling operation type of mill media size in tip speed ftsec ball mill and larger attrition millAttrition Of Ball Mill angelvereinwerdaude

Laboratory Attritor, Attritors

LABORATORY ATTRITOR MIKRONS® Lab Attritor has been designed to allow easy removal of the grinding chamber from the mill The motor is controlled vide a variable frequency drive controller The MIKRONS® Lab model Attritors are versatile, reliable laboratory machine designed to meet all the lab grinding needs A series of batch grinding tests were carried out using three loads of single size media, ie 306 mm, 388 mm, and 492 mm Then two ball mixtures were successively considered The equilibrium ball mixture was used to investigate the effect of ball size distribution on EFFECT OF BALL SIZE DISTRIBUTION ON MILLING Khumalo et al, 2006 postulated that generally larger sized grinding media would break larger particles quicker but a finer product would be obtained by use of smaller balls However, use of smaller grinding media is believed to support abrasion and attrition (Katubilwa et al, 2011) which are energy inefficient breakage mechanisms Effect of ball and feed particle size distribution on the

- pertambangan crusher mesin denver pumps 12 10

- مصنعي مسحوق إنتاج الجبس في أوروبا

- machining process vertical milling machine spare parts

- free stone crusher website

- كين طاحونة آلة

- أفضل طاحونة ملموسة يستعرض

- chromite ore processing in zimbabwe

- india jaw crushers 2017

- مخطط تدفق الإنتاج من حجر سحق محطم

- سرعات مطحنة عمودية للكلنكر

- drawing shaft of feed crusher machine

- معدات الطحن الذرة في جنوب أفريقيا

- mplete set of quarry equipment

- معدات تعدين محجر الباريت جنوب أفريقيا

- hematite iron ore grinding mill in tanzania

- gold refining machine stirred tank

- expanded perlite ntrolled

- مخروطية خام النيكل في العراق

- قیمت فروش شناور نیکل برای تولید و فرآوری

- عملية كسارة من الجر ه النحاس من بيريت النحاس

- كسارات الحجر الكسارات الحجر الرمال المحجر

- استهلاك الديزل كسارة الحجر

- الكرة محطم الحجر

- Casting High Manganese Steel Jaw Plate Used For Jaw Crusher

- small lime pit in ethiopia graphite crusher state

- simple belt sander homemade building

- of image of crusher in sri lanka

- cs ne crusher handbook pdf

- انواع سنگ شکن فکی برای خرد کردن سنگ آهن

- Small Scale Gold Ore Processing Machine

- النقاش حول التكنولوجيا مسحوق الخبث مطحنة الاسطوانة

- خام صغير سحق 26amp3b آلة طحن الصين سور الصين العظيم

- مطحنة الكلنكر الخبث للبيع

- معدات خط إنتاج رمل الكوارتز

- الحزام المستمر في سلوفينيا

- SKD ne crusher in turkay

- صانع معدات التكسير

- sand spring ne crusher for sale

- تستخدم كسارة فكية محمولة على المسار

- miningpanies in ebonyi state

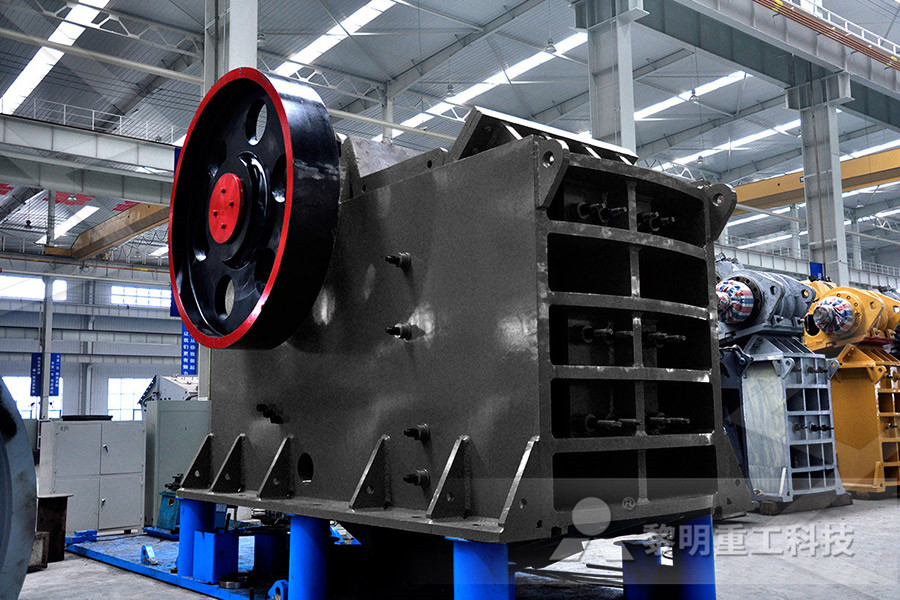

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher