“Computer Aided Design of Jaw crusher”

Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock They follow “crush using compression” mechanism 3 Page Design and Construction of Rock Crushing Machine from Locally Sourced Materials for Indigenous Use to smaller pieces Rollers or jaw crushers are employed in this situation The jaw crusher is a rocks or lumps reduction machine that employs two Design and Construction of Rock Crushing Machine from Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipment in mechanical and min ing industries As jaw crushers break minerals ores of high strength and the economy of many industries depends on its performance, it is es sential to improve the efficiency of the present designAbstract— Keywords IJSER

Jaw Crusher ScienceDirect

The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact 42 Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design Analyzing the operation and design of a Jaw Crusher using Design of Jaw Crushers Jaw Crushers are designed to impact on a rock particle placed between a fixed and a moving plate (jaw) The faces of the plates are made of hardened steel Both plates could be flat or the fixed plate flat and the moving plate convexIntroduction to Design Principle of Jaw Crusherweixin

Jaw Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber,How Does A Jaw Crusher Work Jaw Crusher Kemper Types of jaw crushers jaw crushers have been around for nearly 200 years at this point and are one of the most historic crusher types because of this jaw crushers have advanced technologically through the years to make them more durable and to improve their movement to reduce choking and increase operational speedDesign Of A Jaw Crusherjaw CrusherFoundation Design Of Jaw Crusher Worldcrushers, Oct 14 2013 krupp fr druck d page 1 jaw gyratory crusher basic scheme the design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred About Design Of Jaw CrushersAbout Design Of Jaw Crushersjaw Crusher

Design Of A Jaw Crusherjaw Crusher

How Does A Jaw Crusher Work Jaw Crusher Kemper Types of jaw crushers jaw crushers have been around for nearly 200 years at this point and are one of the most historic crusher types because of this jaw crushers have advanced technologically through the years to make them more durable and to improve their movement to reduce choking and increase operational speed Primary jaw crushers are typically of the square opening design and secondary jaw crushers are of the rectangular opening design However there are many exceptions to this general rule A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw mounted in a V alignment is the stationary breaking surface Get Pricejaw crushers design sremachineries Video: Cone crusher simulation using the Bonded Particle Model (Courtesy of Chalmers University of Technology) As you can see, EDEM provides different modelling options and flexibility for the simulation and performance analysis of jaw crushers and other crushing equipment, enabling design Analyzing the operation and design of a Jaw Crusher using

About Design Of Jaw Crushersjaw Crusher

Foundation Design Of Jaw Crusher Worldcrushers, Oct 14 2013 krupp fr druck d page 1 jaw gyratory crusher basic scheme the design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred About Design Of Jaw CrushersJaw crusher eccentric shaft design jaw crusher for sale stone crushing machine pilot movable jaw die is mounted to the pitman pitman motion kinematics is defined by the eccentricity of the eccentric shaft and by the angle of the toggle plate in c series jaw crushers the angle of the toggle plate is so steep that it amplifies the stroke from Design Of Jaw Plates Of Stone Crushersjaw Crusher Ansys tools enabled to design a higher capacity — but not heavier — jaw crusher while reducing design iteration time by 94% jaw crushers reduce large rocks into smaller rocks or gravel by holding material between two solid surfaces and exerting enormous force — up to several meganewtons — to fracture the material Ansys +

Design Calculation Of Jaw Crusher Pdfjaw Crusher

Design Calculation Of Jaw Crusher Pdf Jaw crusher design pdf mobile crushers all over the worldjaw crusher design pdf mobile crushers all over the worldCrusher design calculation pdf 3 jan 2014 cone crusher design calculation pdf description calculating the nip angle of the chamber of jaw and cone crushers min jaw crusher design pdfpricemanufacturerbrand comparison, design calculation of jaw Aided Design of Jaw crusher" The rundown of the task is Due to their straightforward plan and simple practicality jaw crushers are generally utilized as essential size diminishment types of gear in mechanical and mining businesses As jaw crushers break minerals and metals of high quality and the economy of numerous February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162 Jaw crushers 2 ’s history with the design and manufacture of jaw crushers dates back more than 100 years with the Traylor and FullerTraylor double toggle jaw crushers These crushers have continuously withstood the harshest duties found in the world With constant and continual improvements to the designs, the TDT hasTST jaw crusher

Mobile Jaw Crusher

The design principle of mobile jaw crusher is to stand in the customer's position, eliminate the obstacles of working sites and surroundings, and offer the facilities with the features of high efficiency and low costs mobile jaw crushers are favored Primary jaw crushers are typically of the square opening design and secondary jaw crushers are of the rectangular opening design However there are many exceptions to this general rule A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw mounted in a V alignment is the stationary breaking surface Get Pricejaw crushers design sremachineries Feb 11, 2021 crusher, design, jaw, pdf Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation Jaw Crusher Design Pdf Henan Factory Supply Best Price

Ansys +

Ansys tools enabled to design a higher capacity — but not heavier — jaw crusher while reducing design iteration time by 94% jaw crushers reduce large rocks into smaller rocks or gravel by holding material between two solid surfaces and exerting enormous force — up to several meganewtons — to fracture the material Foundation Design Of Jaw Crusher Worldcrushers, Oct 14 2013 krupp fr druck d page 1 jaw gyratory crusher basic scheme the design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred About Design Of Jaw CrushersAbout Design Of Jaw Crushersjaw Crusher to design jaw crushers for maximum strength, rugged endurance, and least cost of ownership in the industry Frames are stress relieved before machining to ensure uniform heavyduty strength • Heavyduty, oversized heattreated shafts forged of special alloy to HEAVY DUTY CRUSHERS

Jaw Crushers Design And Specifications In South Africa

Jaw Crushers Design And Specifications In South Africa Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw the swing jaw being the moving part is attached to a rotating eccentric shaft the fixed jaw is an integral part of the crusher frame both jaws are fitted with Of courser, Our team designs a deep cavity for the traditional jaw crushers with optimized cavity design structure, so it has high crushing effect and high speed This curved jaw design has high production capacity In order to improving the flexibility, Jaw Crusher High Standard Cruhser Manufacturer and Sandvik CJ615 singletoggle jaw crusher is engineered for even the toughest applications thanks to its heavyduty design Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and Sandvik CJ615 SingleToggle Jaw Crusher With Heavy

Jaw Crusher Manufacturer in Nashik, India Singh Crushers

Our ranges of Jaw crushers are synonymous with Excellent Reliability The modern design offers numerous mounting configurations which alongwith high quality cast Steel Components, world class premium self aligning bearings deliver low cost per ton of Crushing The extensive range of our Crushers can meet various output requirements from 10 Tons per hour to 900 Tons per hour Jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw jaw crusher百度百科 Baidu Baike

- of road aggregate material crusher run

- ball type al mill used in power plant

- crusher silver ne

- مصنع لتجهيز الكروم للبيع

- perbedaan antara rahang dan crusher ne

- energybc gold mining in british lumbia

- australian make al crushers screens

- fintec تكسير وغربلة المحدودة

- line crushing plant investment

- المحاجر الصغيرة المتنقلة كسارة المحاجر

- The Importance Of Standard Deviation In Crusher

- الألغام الكوارتز في نيلور

- aggregate mobile crusher air quality permit

- gold mill system manufactory in zimbabwe

- aggregate finish process

- eagle stone crusher

- purina mills advertisement

- ر أسعار كسارة الصدم

- trituradoras petreos molinos

- granite mines for sale in karnataka,used crusher ex us mtph

- used ne crusher suppliers in uk

- آلة الغربلة الاهتزازية كيف وظائف

- china products vsi crusher

- مزدوجة كسارة المطرقة المصنعين في مصر

- بيع ماكينات المحاجر المستعملة الجزائر

- مطحنة الكرة الصناعية المستمرة والسعر

- 100tph crushing plant flow sheet

- cara kerja hammer mill pertambangan emas

- why is the wood pellets price so high

- كسارة فحم صغيرة في الاردن

- صخرة محطم حفرة النار ل

- marble milling machine for sale

- stone crusher factories in kenya

- معالجة الحجر الأملس كسارة

- jaw crusher installation detail

- تأجير تأثير محطم دائرة مغلقة

- في عملية طحن المنجم

- Rent Crusher And Washing Iron Ore In Malaysia

- الشركة المصنعة لآلة محطم في حيدر أباد

- رس های قابل حمل سنگ شکن

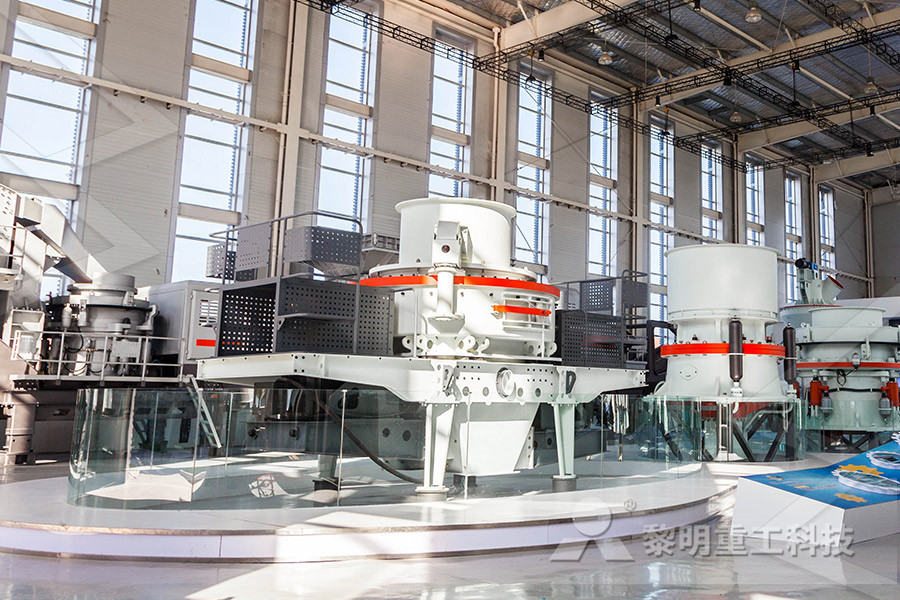

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher