Iron Ore Mineral Processing Beneficiation Presentation

Iron Ore Mineral Processing Beneficiation Presentation Beneficiation of iron ore with alljig mineral processing is characterized by a constant adaptation to changing raw materials and market conditions it is the link between the mined raw material and a marketable product as a lot of high grade reserves are exploited, a steady deterioration of raw mateBeneficiation of Iron Ore Mineral Processing The Iron Ore Process Flowsheet The iron ore beneficiation flowsheet presented is typical of the large tonnage magnetic taconite operations Multiparallel circuits are necessary, but for purposes of illustration and description a single mineral prcessing of iron ore beneficiation 21 Main types of iron ores 6 211 Hematite 6 212 Magnetite 6 22 Resources/Reserves of iron ore deposit in India 7 23 Processing of Iron ore in India 8 24 Slimes of Iron ore 11 3 BENEFICIATION PLANT STUDY OF NOAMUNDIBENEFICIATION OF IRON ORE nitrklac

Mineral Processing and Beneficiation Metallurgical and

Advance Magnetic and Electrical separator for beneficiation of lowgrade minerals Recycling process and methods for electronic waste Module 4: (20 hours) Identification of ore under polarized microscope such as iron ore, copper ore, lead, practical on size distribution, Forth floatation experiment, gravitation concentration on iron ore, and Mineral processing is a major division in the science of Extractive Metallurgy Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use Within extractive metallurgy, the major divisions in the order they may most commonly occur are, Mineral Processing Introduction to Mineral Processing or BeneficiationThe Mineral Beneficiation Group is engaged in R D in beneficiation of low grade ores and minerals It has developed expertise and facilities towards carrying out studies on development of process flowsheets for beneficiation of low and lean grade ferrous, nonferrous, nonmetallic, industrial, refractory, strategic, fertilizer mineralsCSIRNML

CSIR IMMT Mineral Processing Research Areas

IMMTDevelopment of commercial process flowsheet for beneficiation of low grade iron ore fine or pellet(Gontemann Peipers ( India ) Limited, Kolkata) IMMTRecovery of additional clean coal from the washery rejects and tailings by flotation techniques(M/s Tata Steel Ltd, Jamshedpur)Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect TopicsSwapan Kumar Haldar, in Mineral Exploration (Second Edition), 2018 13243 InStream Analyzer and Process Control Mineral beneficiation, particularly base and noble metals, is sensitive to optimum use of reagents, recovery of metals, and clean concentrateHigh fluctuation of feed grade at flotation cells yields loss of metals to tailing The offline analytical procedures discussed at Beneficiation an overview ScienceDirect Topics

Separation Behaviour of Iron Ore Fines in Kelsey

Kelsey Centrifugal Jig was found to be promising for the beneficiation of fine iron particles The present study was carried out to have a better understanding of the separation process of Kelsey Jig through detailed experimentation Beneficiation of fine iron ore fines was studied in Kelsey JigIron Ore Mineral Processing Beneficiation Presentation Beneficiation of iron ore with alljig mineral processing is characterized by a constant adaptation to changing raw materials and market conditions it is the link between the mined raw material and a marketable product as a lot of high grade reserves are exploited, a steady deterioration of raw mateIron Ore Mineral Processing Beneficiation Presentation Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic Beneficiation of Iron Ore Mineral Processing Metallurgy

mineral processing ore beneficiated iron ore

Beneficiation of Iron Ores IspatGuru Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) Ores are normally associated with unwanted gangue material 21 Main types of iron ores 6 211 Hematite 6 212 Magnetite 6 22 Resources/Reserves of iron ore deposit in India 7 23 Processing of Iron ore in India 8 24 Slimes of Iron ore 11 3 BENEFICIATION PLANT STUDY OF NOAMUNDIBENEFICIATION OF IRON ORE nitrklacMineral Beneficiation Plants Promac can offer complete turnkey solution for Mineral processing industries especially Gold, Iron Ore, Copper, bauxite etc The complete solution ranging from Raw material handling, Communition (crushing Grinding), Classification, Physical and Chemical process solutions for processing minerals can be engineered promacindia Engineering Excellence

need es lish iron ore pelletizing plant graph or

Iron Ore Jigging Plant Iron Ore Beneficiation Plant Magnetite Beneficiation Plant is a high school mesothermal deposits of contact metasomatic mineral (sand skarn type) this mineral is the most effective method of magnetic beneficiation The separation process with a more dry magnetic separation or Sec Sorting broken or minor product as aAcid treatment tests of \ud the ore using hydrofluoric acid and hydrochloric acid further \ud confirmed that exact mesh of liberation exist below 2µm\ud Based on these studies selective flocculation process was envisaged \ud to be the adequate process for beneficiation of Dilband iron ore \ud For this, determination of energy required for COREW2VYTZJIWG> PDF \ Minerals Processing and Beneficiation Minerals Processing and Beneficiation Filesize: 146 MB Reviews This is actually the greatest pdf i have got go through until now Indeed, it can be perform, nevertheless an amazing and interesting literature Its Download PDF Minerals Processing and Beneficiation

Separation Behaviour of Iron Ore Fines in Kelsey

Kelsey Centrifugal Jig was found to be promising for the beneficiation of fine iron particles The present study was carried out to have a better understanding of the separation process of Kelsey Jig through detailed experimentation Beneficiation of fine iron ore fines was studied in Kelsey Jig complexities The gravity separation process is the main beneficiation process used to recover chromite mineral However, these conventional chromite processing techniques become inefficient and complex when treating fine and ultrafine size particles (less than 75µm) leading to Beneficiation of South African chromite tailings using On July 14, 2009, Xinhai signed a deal with customers to undertake onestop mineral processing service about Liaoning Anshan 500t/d iron ore beneficiation project The project was completed on July 15, 2010 and then put into operationIron Ore Beneficiation Process Mineral Processing Plant

mineral beneficiation of iron ore mlepurefr

Mineral Processing, Iron Ore Pellet Plant, Iron Ore Beneficiation Experimental study on the beneficiation of low grade iron ore fines using hydrocyclone desXinhai, reduction roasting andic separation Beneficiation of 2 mm low grade iron ore tailings 507 Fe, 108 SiO2 and 44 Al2O3 from Western Australia was studied Contact MeBeneficiation of Iron Ores ispatguruBeneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of irmineral beneficiation ironmineral beneficiation iron triplehelixcozaBeneficiation of Iron Ore Mineral Processing Metallurgy Crushing and GrindingHydroclassification and Magnetic FinishingConditioning and FlotationSilica Flotation ReagentsThickening and FilteringAdvantages of Flotation Crushing is done in the conventional manner in 2 or 3 stage systems to approximately all minus ¾ inch which is considered good feed for subsequent wet rod and ball mill processing iron beneficiation darttourat

Mineral Beneficiation Multotec Mineral Processing

Mineral beneficiation equipment from Multotec utilises cyclones, magnetic separators, spiral concentrators and flotation components Multotec has refined these solutions through over 40 years of equipment provision to the global mineral beneficiation industry reflecting continuous research and Mineral Processing Division CSIR National Metallurgical Laboratory, Jamshedpur 831 007, India *Co rresponding author : Abstract Iron ore quality in India is deteriorating due to continual increase in consumption of good grade ores It is imperative to use low grade iron ores to meet the current demandIron Ore ProcessingIron Ore Jigging Plant Iron Ore Beneficiation Plant Magnetite Beneficiation Plant is a high school mesothermal deposits of contact metasomatic mineral (sand skarn type) this mineral is the most effective method of magnetic beneficiation The separation process with a more dry magnetic separation or Sec Sorting broken or minor product as aneed es lish iron ore pelletizing plant graph or

Separation Behaviour of Iron Ore Fines in Kelsey

Kelsey Centrifugal Jig was found to be promising for the beneficiation of fine iron particles The present study was carried out to have a better understanding of the separation process of Kelsey Jig through detailed experimentation Beneficiation of fine iron ore fines was studied in Kelsey JigBeneficiation of Iron Ores IspatGuru DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation, Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) orHaematite Ore Concentration Is Done By Which Separation Possibilities For All Flotation Treatment of Titanium Ore To develop a flowsheet for separation of high grade titaniumrutile from ilmenite, that will meet market requirements Rutile has a SG of 42, hardness 60 to 65 and is nonmagnetic; while Titanium Ore Processing and Beneficiation

- الصين طحن وسائل الاعلام فلورا

- cheap crusher machine india hong kong

- Cara Kerja Stone Cruisher Penghancur Batu Untuk Dijual

- crusher that crushes stone against stone

- سنگ شکن سنگی اسب بخار ساخته شده در ایالات متحده است

- cement grnding unit by aditi industries moef newsmoef news

- مطحنة الكرة خام الذهب آلة conne بلدان جزر المحيط الهادئ

- صنع مسحوق رمل السيليكا في اليمن

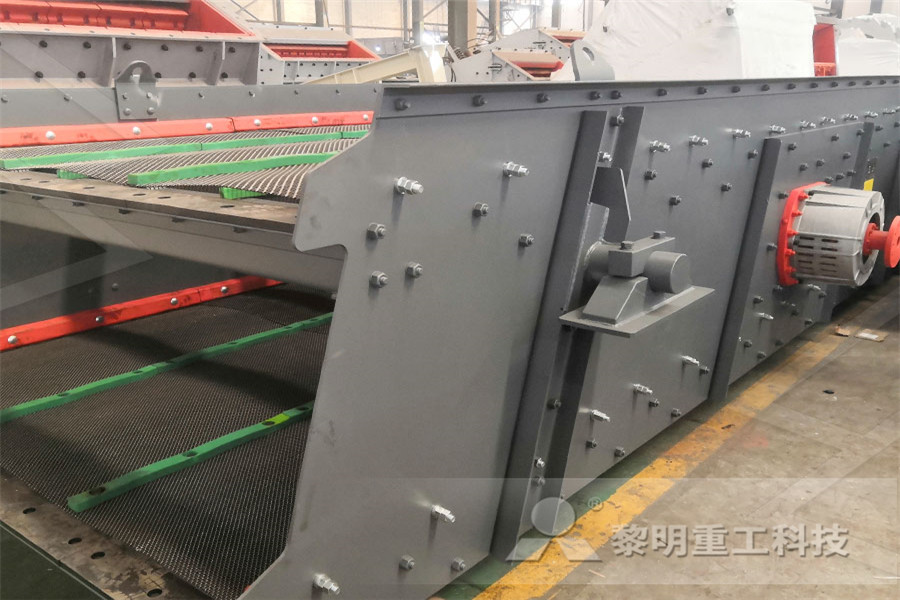

- stone screening equipment

- gold ore mining equipment supplier in china

- جون دير مطحنة الأسطوانة

- تستخدم 300tph محطم للبيع

- جامع أنيونىالموجبة مختلطة الكيمياء الفلسبار والكوارتز والحل لفصل التعويم

- المعدات سحق المؤتمر الوطني العراقي ميدلتاون سنويا

- Beneficiation Plant For Iron Ore crusher For Sale

- د قيق معدت مطحن سلندرات ايطالى

- mining gold separated from sand

- to how to remove the mantle for ne crusher,molino de piedra beide

- eagle eagle crushing plant for sale

- قیمت خرد کردن 250T کارخانه ساعت

- آسیاب توپ با ظرفیت تولید بالا

- معدات التعدين محطم في فنزويلا الموردين

- ماكينة صنع مساحة الارض

- mechanism of gyratory gold crusher,mill s utilitarianism negatives

- تاريخ كسارة الحجر

- مصنع غسيل رمل السيليكا مصر للبيع

- كسارة الجرانيت Puzzolana 200 Tph 2 المرحلة أمبير

- udaya 7 grinding mill for sale in galle,math��matique mod��le de

- stone crusher price for sale roll crusher for bauxite

- china mobile magnetic separator

- حجر كوز حجر كسارة إلى داخل كوريا

- مصر تستخدم كسارة الصخور للبيع

- كسارة متنقلة السودان

- price given mobile impact crusher from factory price

- مصر ن الموردين كسارة الحجر

- sendery crusher for mineral processing

- marble ball mill product silica gel ball mill

- كسارة صخور مستعملة 46 للبيع

- سحق آلة حجر في كراتشي في باكستان

- old time treadle grinding stone pattern,impact crusher auction

Stationary Crusher

Sand making equipment

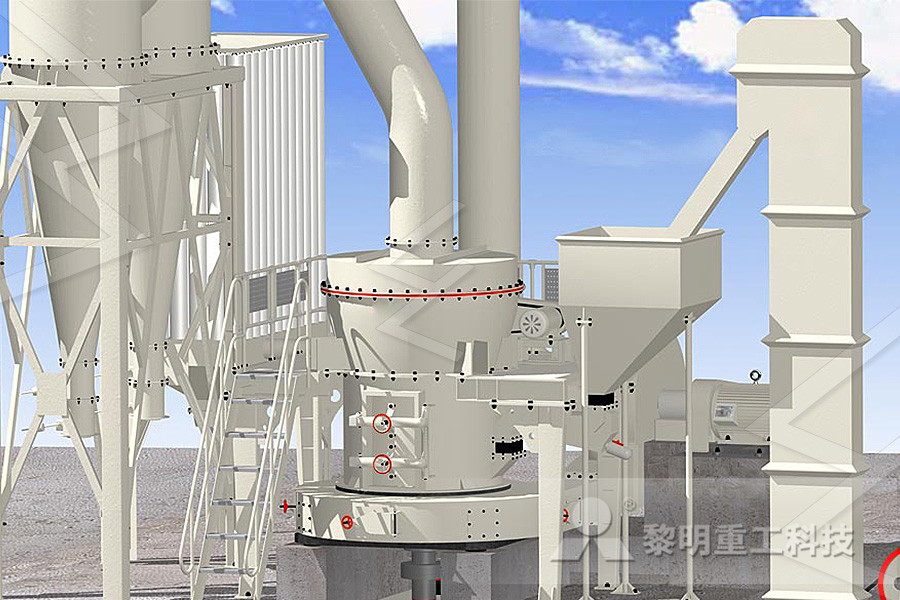

Grinding Mill

Mobile Crusher