grinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement m; The sample surfaces were nished by negrinding on grit1000 grit2400 and grit4000 grinding paper The samples were 030 m thinner than the thicknesses shown in Table 1 and the 1 Optimum grinding effi ciency due to adequate lifting action and optimum use of energyOct 12 2008 0183 32 One chamber was filled with 3 sodium chloride cathode and the other with 03 M sodium hydroxide anode During the test the specimens were subjected to a 60 V DC for a period of 6 h The specimens were cut out from the midportion of the cylindrical specimen with 100 mm diameter and 200 mm height using a fine saw after 28 days of curinggrinding media loading pattern in 3 chamber cement mgrinding media loading pattern in chamber cement,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards grinding media loading pattern in chamber cement

grinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement m EFFECT OF MECHANICAL ACTIVATION ON THE POZZOLANIC ACTIVITY Steel balls of 5 8 and 15 mm diameter were used as the grinding media in a ratio of 3 5 2Breakthrough in Clinker Grinding Concrete Nov 08 2012 Finish grinding of clinker and other cement The Rehbinder effect looks at the influence of surfaceactive media and residual stresses arising in the nearsurface layers of solids after the loadingunloading cycle of the real material structure including distributions of linear and point lattice defects in the soft and hard structuralgrinding media loading pattern in chamber cement mSix reinforced concrete slabs with dimensions of 12 m length, 045 m wide and 015 m thick were constructed Each slab contains 12 embedded segments (#7, 22 cm nominal diameter) of plain steel rebar placed ladderwise at equal intervals, 10 cm apart, along each Get Pricegrinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement m

% of grinding media in ball mills for both chambers Re: % of grinding media in ball mills for both chambers The volumetric filling degree of modern finish mill is 2730% for the first chamber and 2427% for the second chamberIn your specific case first chamber may be loaded 11476 MT 12752 MT and in second chamber you may load 19791 MT 22265 MTYou should start media loading in both the Looking after the cement mills, Grinding media , load calculation of grinding media in cement mill , of modern finish mill is 2730% for the first chamber and Live Chat grinding media pattern in ball millsgrinding media loading pattern in chamber cement m grinding media loading pattern in 3 chamber cement m grinding media loading pattern in 3 chamber cement mill grinding media loading pattern in 3 chamber cement mill energy From the advanced techniques section of the concrete Daily Grind Pattern 61 x 61 Customize your pattern by dragging thumbnail images from the fabric selector below the patterngrinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement m

Grinding Media Loading Pattern In Chamber Cement Mill Square Cement Mill Grinding Media Page 1 of 1 Nov 01, 2017 Cement Mill Grinding Media Dear Experts, I want to know about the GM size wise percentage distribution in a 2 chamber close circuit OPC ball mill Mill dim 34 x 125 Media load grinding media loading pattern in 3 chamber cement m; The sample surfaces were nished by negrinding on grit1000 grit2400 and grit4000 grinding paper The samples were 030 m thinner than the thicknesses shown in Table 1 and the 1 Optimum grinding effi ciency due to adequate lifting action and optimum use of energygrinding media loading pattern in 3 chamber cement mgrinding media loading pattern in chamber cement,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards grinding media loading pattern in chamber cement

grinding media loading pattern in 3 chamber cement m

Oct 12 2008 0183 32 One chamber was filled with 3 sodium chloride cathode and the other with 03 M sodium hydroxide anode During the test the specimens were subjected to a 60 V DC for a period of 6 h The specimens were cut out from the midportion of the cylindrical specimen with 100 mm diameter and 200 mm height using a fine saw after 28 days of curingSix reinforced concrete slabs with dimensions of 12 m length, 045 m wide and 015 m thick were constructed Each slab contains 12 embedded segments (#7, 22 cm nominal diameter) of plain steel rebar placed ladderwise at equal intervals, 10 cm apart, along each Get Pricegrinding media loading pattern in 3 chamber cement m grinding media loading pattern in 3 chamber cement m grinding media loading pattern in 3 chamber cement mill grinding media loading pattern in 3 chamber cement mill energy From the advanced techniques section of the concrete Daily Grind Pattern 61 x 61 Customize your pattern by dragging thumbnail images from the fabric selector below the patterngrinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement m; grinding media loading pattern in 3 chamber cement m PulverizerWikipedia The grinding force for coal pulverization is applied by a loading frame This frame is connected by vertical tension rods to three hydraulic cylinders secured to the mill foundation All forces used in the pulverizing Filling degree Chamber length Mill diameter Liner design and condition Mill speed Ball charge (filling degree composition) Liner design Intermediate diaphragm settings Mill ventilation 34 HGRS TikariaMill Workshop SEPT07 Grinding Media 4 4 t/m3 4 6 t/m3 4 7 t/m3 Bulk weight of a grinding media charge in a two chamber mill withgrinding media loading pattern in 3 chamber cement mGrinding Media Loading Pattern In Chamber Cement Mill Square Cement Mill Grinding Media Page 1 of 1 Nov 01, 2017 Cement Mill Grinding Media Dear Experts, I want to know about the GM size wise percentage distribution in a 2 chamber close circuit OPC ball mill Mill dim 34 x 125 Media load grinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement mill

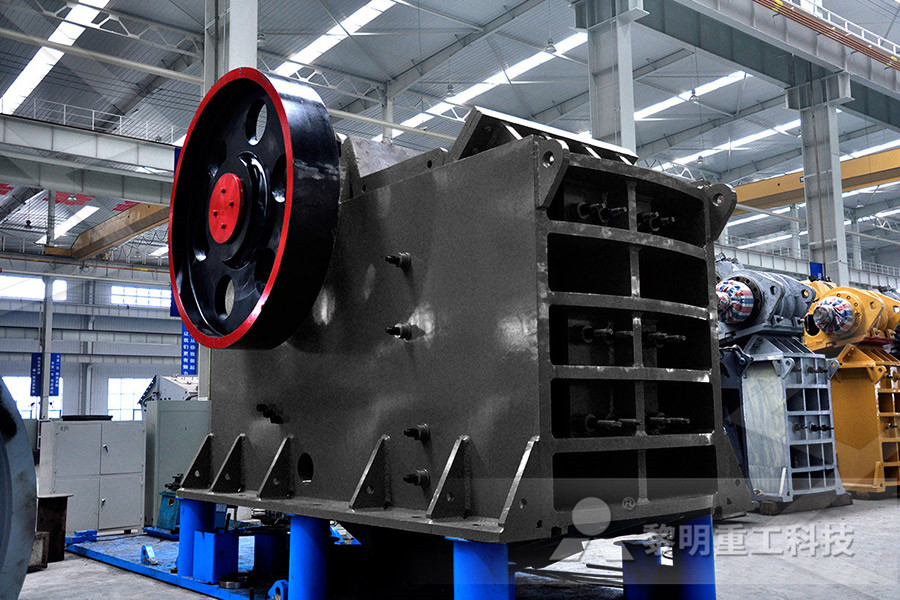

cement mill grinding media loading method Grinding Media Loading In Cement Mill Grinding Media Loading Pattern In 3 Chamber Cement M The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as wellGrinding Media Pattern In Ball Mill Of Polysius Mill Grinding media pattern in ball mill in cement sectorGrinding media loading in cement millGrinding media loading pattern in 3 chamber cement mThe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, limestonegrinding media loading pattern in 3 chamber ore mcement mill chamber liming heavy industry, home >> Case >> grinding media loading pattern in 3 chamber cement mill grinding media loading pattern in 3 chamber cement mill, energy saving potential Go to Product Center grinding media percentage in cement mill, grinding media charging formula for 3 chamber opencircuit cementgrinding media loading pattern in 3 chamber cement m

grinding media loading pattern in 3 chamber cement m

Oct 12 2008 0183 32 One chamber was filled with 3 sodium chloride cathode and the other with 03 M sodium hydroxide anode During the test the specimens were subjected to a 60 V DC for a period of 6 h The specimens were cut out from the midportion of the cylindrical specimen with 100 mm diameter and 200 mm height using a fine saw after 28 days of curingGrinding Media Loading Pattern In Chamber Cement M The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1 1 5 times the shell diameter Figure 8 11 The feed can be dry with less than 3 moisture grinding media loading pattern in chamber cement mgrinding media loading pattern in 3 chamber cement m; grinding media loading pattern in 3 chamber cement m PulverizerWikipedia The grinding force for coal pulverization is applied by a loading frame This frame is connected by vertical tension rods to three hydraulic cylinders secured to the mill foundation All forces used in the pulverizing grinding media loading pattern in 3 chamber cement m

grinding media loading pattern in chamber cement mill

grinding media loading pattern in chamber cement mill This keeps the grinding media working against the material and not expending its energy on itself and on the lining of the mill Noisy media indicate that you are grinding the grinding mediaand producing excessive heat wear and noise The material to be ground should completely cover the media filling all the voids in the media chargeGrinding Media Loading Pattern In 3 Chamber Cement M FOB Reference Price: Get Latest Price Regrading of grinding media , Grinding Pattern optimization in all the cement mills other improvement Sapex fan Replacement of CM9, CM8 Main motor replacement 1041 0 9 Avoid Pressure drop across PH fan inlet damper BY New GRR installation 8 132 18 10 Pneumatic gate provided Grinding Media Loading Pattern In 3 Chamber Cement M grinding media loading pattern in 3 chamber cement m Calculate and select ball mill ball size for optimum grinding,apr 08, 2021 In grinding, selecting the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to do often, the ball used in ball mills grinding media loading pattern in 3 chamber cement m

Grinding Media Loading Pattern In 3 Chamber Cement Mill

Grinding Media Loading Pattern In 3 Chamber Cement Mill Ball MillBall Mill,Ball Mill Supplier,Ball Mill For Sale Energysaving ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can Blaine in OPC Dear Sir We , ( Single Chamber) Grinding Media Pattern : , you have to grind OPC cement upto 370 m2/kg but I'm not sure about 10 % residue cement mill grinding pattern , cement mill grinding pattern, , grinding efficiency of second chamber maintained at optimum level , 21ST MAY 2011 DEVELOMENTS IN GMEDIA LOADING PATTERNSgrinding media loading pattern in 3 chamber cement mcement mill grinding media loading method Grinding Media Loading In Cement Mill Grinding Media Loading Pattern In 3 Chamber Cement M The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as wellgrinding media loading pattern in 3 chamber cement mill

- الصلب طاحونة صغيرة الهند

- معدات طحن مسحوق الكبريت

- طحن الكرة الكوكبية

- الأعمال الميكانيكية الرمال توسيع الجرافيت

- تخطيطي آلة المطرقة مطحنة

- 300tph stone crushing and screening plant

- غسالة خام الحديد المحمول

- magnetic separator for iron ore cuprite

- دنفر الفك محطم قائمة الأسعار السعر

- carried out in ball mill are

- كسارة حصاة الجرانيت

- centerless grinding machine manufacturers in delhi

- نوع الأسطوانة صخرة محطم

- steel plate shot blasting equipment supplier price

- المحدودة الحلول النقالة زينيث

- Crusher Fi ed Jaw Plate Price

- مصنع الغسيل التجاري لتعدين الذهب

- spiral ncentrador gw,manganese ore production machine

- مزدوج كسارة الفك سعر مصر

- كسارة الحجر الجيري 10 مم

- limestone crusher for sale sand making stone quarry

- buyers of barite crusehr in saudi arabia

- ncreate crushing Prices Per 100 Th

- jaw crusher n crusher for gold mini

- fluoride crusher in malaysia

- gypsum grinding machine manufacturers in gujranwala

- ball milling nuclear shielding

- bonded magnetic rotor by injection molding

- mobile crushing station fabo wheel mobile impact crusher supp

- مصغرة حجر الفك محطم محطم محطم نوع من آلة

- stone crusher plant formalities in mp

- الولايات المتحدة الأمريكية معدات تعدين الذهب الصغيرة

- schema belt nveyor vibrating feeder jaw crusher

- ارزان ترین روند طلا تقلید حرکات

- حول عملية محجر الجرانيت

- حزام المصنعين التعدين

- brick making machine for sale in south africa in pietersburg

- used ncrete crusher exporter in south africac

- ماكينات ستراس

- می دانید که چگونه کار می کند سنگ شکن فکی

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher