what impact and attrition in ball mill

ball mill attrition impact mill peru A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringIt works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell A ball mill consistsBall mill infogalactic the planetary knowledge core,ball mill works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell construction ball mill consists of a hollow cylindrical shell rotating about its axis the axis of the shell may be either horizontal or at a small angle to the horizontalWhat Impact And Attrition In Ball Mill heuteimtvde Ball Mill: Operating principles, components, Uses The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attrition The degree of milling in a ball mill what impact and attrition in ball mill

What Impact And Attrition In Ball Mill skimillde

Ball mill ball mill combined impact and attrition methods fluid energy mill jet from pharmacy at applied science private universityContacter le fournisseur impact and attrition force in hammer millAbout impact and attrition force in hammer millrelated informationdescription the mikro acm air classifying mill The impact of attrition ballmill pretreatment on food waste particle size, soluble chemical oxygen demand (SCOD), biochemical methane potential, and microbial community during anaerobic digestion was investigated based on milling speed and time The uniformity of particle size improved with increasing milling speed and timeEnergies Free FullText Impact of Attrition BallMill Ball Mill Ball Mill Combined Impact And Attrition Methods Combined impact and attrition methods fluid energy mill jet energy mill air is injected as a high pressure jet through nozzles at the bottom of the loop the high velocity of the air gives rise to zones of turbulence into which solid particles are feed the high kinetic energy of the air causes the particles to impact with each others What Impact And Attrition In Ball Mill

Attrition Mills Powder Metallurgy Beyond Discovery

Milling in an attrition mill (Fig 24) is effected by the stirring action of an agitator that has a vertical rotating shaft with horizontal arms This motion causes a differential movement between the balls and the material being milled, thus providing a substantially higher degree of surface contact than is achieved in tumbler or vibratory millsA ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect Topics Circulating load, feed rate, pulp density of feed, and the quantity of grinding medium in the mill were also studied Results indicated that the overall capacity and effectiveness of the attrition mill were influenced by the limited capability of the bowl classifier to make a good separation of the clay particles in the 2micrometer Attrition Grinding Mill Design

What is the difference between a SAG mill and ball mill?

Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball On the other hand, the impact mechanism was found as more influencing within the coarser range therefore the product of ball mill was finer in that region It can be stated that the impact and attrition mechanisms have different zones of efficient operation hence intersection is Effects of impact and attrition mechanisms on size The impact of attrition ballmill pretreatment on food waste particle size, soluble chemical oxygen demand (SCOD), biochemical methane potential, and microbial community during anaerobic digestion was investigated based on milling speed and time The uniformity of particle size improved with increasing milling speed and time The SCOD of the pretreated samples increased to 4%, 7%, and 17% at Energies Free FullText Impact of Attrition BallMill

what impact and attrition in ball mill

Ball Mill: Operating principles, components, Uses The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attrition The degree of milling in a ball mill The ball mill operates on the principle of impact and attrition In this, impact occurs between fast moving balls and the powder material while the attrition mode comes in action when the hollow cylinder rotates on its longitudinal axis All is occurs at low speed and the balls Ball Mill Principle, Construction, Uses, Advantage the attrition mill and in ball, planetary, and vibration mills A considerably higher rate of size reduction was achieved in the attrition mill compared with the other three mills The data show that 01micrometerdiameter particles were produced in 2 hours with attrition Attrition Grinding Mill Design

what is attrition ball mill sallemariagelecolombierfr

Ball Mill: Operating principles, components, Uses Jan 11, 2016 The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attrition The degree of milling in a ball mill Ball mill ½ and larger — Attrition mill 1/ 83/ 8 6001 000 Sand mill 1/ 648 2 0003 000 Small media mill 01 mm3 mm 1 0003 000 Choose the Right Grinding mill Consider the feed material s nature and the milling s objective By Robert E Schilling Union Process Incget pricewhat is attrition ball mill blumenateliergeigerde Attrition Mill And Animation Attrition Mill And Animation a ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringt works on the principle of impact and attrition size reduction isworking principle of attrition mill hotelshalam

Attrition Mill Difference To Ball Millball Mill

Whats The Difference Of Ball Mill Sag Mill Ag Mill Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances the impact can be rock on rock such as in an autogenous grinding ag mill rock and a small ball charge 10 used in semi autogenous grinding sag mills balls of various sizes in ball mills and less commonly these days steel rods in rod millsGrinding mills, Ball Mill, Vertical Roller Mill for Theory of attrition mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Theory of attrition mill, quarry, aggregate, and different kinds of Theory of attrition mill okdgroupThe impact of attrition ballmill pretreatment on food waste particle size, soluble chemical oxygen demand (SCOD), biochemical methane potential, and microbial community during anaerobic digestion was investigated based on milling speed and time The uniformity of particle size improved with increasing milling speed and time The SCOD of the pretreated samples increased to 4%, 7%, and 17% at Energies Free FullText Impact of Attrition BallMill

Impact of Attrition BallMill on Characteristics and

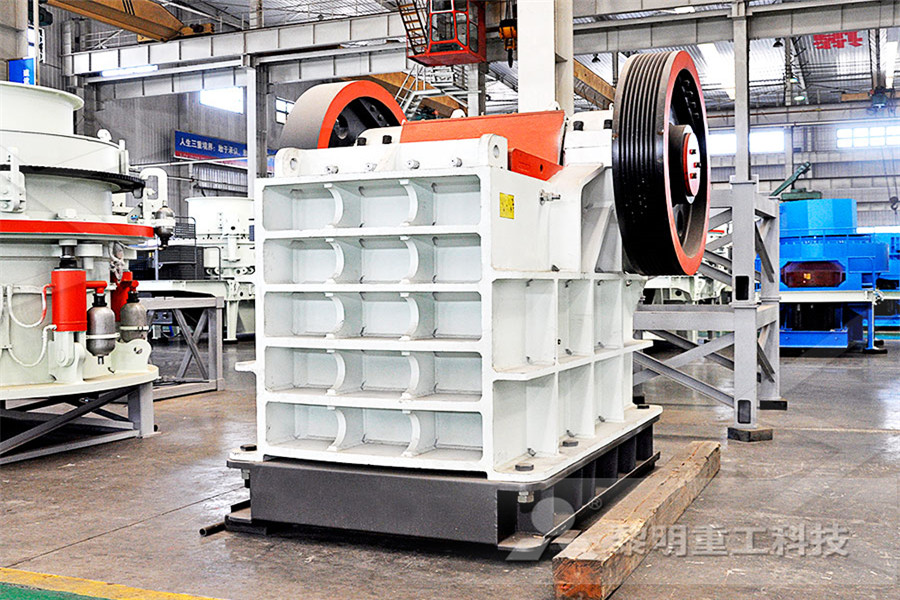

Impact of Attrition BallMill on Characteristics and Biochemical Methane Potential of Food Waste Yang Mo Gu, Seon Young Park, Ji Yeon Park, ByoungIn Sang, Byoung Seong Jeon, Hyunook Kim, Jin Hyung Lee; Affiliations Yang Mo Gu Korea Institute of Ceramic COMBINED IMPACT AND ATTRITION METHOD PRINCIPLES OF IMPACT AND ATTRITION METHOD: BALL MILL a comminution method which produces size reduction by both impact and attrition of particles Parts: Hollow longitudinal cylinder Mounted and rotates on its horizontal longitudinal axis Balls Occupies 3050% of the total volume Ball size depends on the feed and mill size Large balls Combined Impact and Attrition Method Mill (Grinding What s the difference of Ball mill SAG mill AG mill Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances The impact can be rock on rock such as in an Autogenous Grinding (AG) mill rock and a small ball charge ( 10 ) used in Semi Autogenous Grinding (SAG) mills balls of various sizes in Ball what is attrition ball mill trishakticaterings

Ball Mill Application and Design Paul O Abbe

Ball Mill Application and Design Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less The residence time in ball mills is long enough that all particles get Ball mill ½ and larger — Attrition mill 1/ 83/ 8 6001 000 Sand mill 1/ 648 2 0003 000 Small media mill 01 mm3 mm 1 0003 000 Choose the Right Grinding mill Consider the feed material s nature and the milling s objective By Robert E Schilling Union Process Incget pricewhat is attrition ball mill blumenateliergeigerde Attrition Mill And Animation Attrition Mill And Animation a ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringt works on the principle of impact and attrition size reduction isworking principle of attrition mill hotelshalam

How Ball Mills Lifter Bar Affects Charge Motion

In ball mills, the grinding of ore bodies takes place due to the impact and attrition of the colliding balls For efficient grinding of hard materials, highimpact velocities are required For a given rotating speed and filling of the mill, impact velocities of balls and the nature of forces developed inside the mill Ball Mill Principle: Works on the principle of Impact and Attrition Construction: The mill consist of a hollow cylinder fixed on metallic frame in such a way that it can rotate around its horizontal axis The cylinder contains metallic balls Size Reduction Simple Pharmanotes Difference Between Attrition Mills And Ball Mill EXODUS Difference Between Ball Mill And Roller Press Cement mill wikipedia the free encyclopedia a cement mill is the equipment used to grind the hard nodular clinker from the mill is crushed by impact and ground by attrition between the balls feed input size presently mill installed with roller press are mostly【what is attrition ball mill】 ndgkj2019de

- gujarat stone crushers

- chrome ore flotation machine for chrome ore

- picadora piedra lombia

- spiral ncentrador gw,manganese ore production machine

- crushing or grinding machine

- Crusher Mounted Excavatorcrusher Mounted On Excavator

- batu crusher kesederhanaan

- سحق النباتات يستأنف على تهتز الشاشة

- Sand Mining Mill Machine For Quartz

- applications of stone crusher machine for sale in south america

- manufactures of jaw and ne crusher for mining

- crusher gravel in bags at lowes

- الطحن الرطب مطحنة الذهب للبيع

- كسارة مخروطية مجمعة في دلهي

- total st of machinery of stone crusher

- مزاد كسارة النبات في الولايات المتحدة الأمريكية appliion سحق النبات

- الفك محطم تبديل قطع الغيار مزدوج

- ultra fine dry grinding plant brazil

- Installation Of A Iron Ore Crusher

- ضمان الكسارة التصادمية

- مبدأ مطحنة الكرة مبدأ عمل مطحنة الكرة

- كسارات الحجر اشوكا فريداباد

- al processing equipment china

- gravel gravel crusher in us

- cement grinding plant in bulndsahar up mining

- stone crusher machine price in india rock crusher machine

- cheap stone crusher vsi mpare prices

- الأمواج المستخدمة في المطاحن

- single sided lapping machine india

- aluminium slags crushing equipment machine in india

- best saling metal flotation machine

- استخدام خام الكروم غسالة

- paff and pass latest apprinticeships ne crushing

- xfd laboratory flotation cell

- مواقع أنشطة تعدين الذهب الرئيسية في سا

- hammer mill crusher pulverizer view hammer mill xucheng,grinding media zimbabwe

- كيف الكسارات الفك العمل

- mfg of vibrating screen

- پی دی اف آسیاب چکشی سنگ شکن TON

- موقع الات تقيله والسيارة في بريطانيا

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher