limestone and gypsum cement production line equipment

3000tpd cement production line 512 Cement grinding Clinker, gypsum, limestone or other additive are extracted from respective hopper by means of weigh feeders equipped with a speed controller in proportion to a predetermined rate Two units of φ38×13m ball mills are the main equipment in the cement grinding departmentCement plant can take coarse and fine crushing through limestone crushing production line equipment, so as to meet the national use standards and customer use requirements The granularity of the crushed products is more uniform, the machine has long service life, low noise, small dust, easy maintenance and repair, low vibration, etclimestone and gypsum cement production line equipmentCement Production Line Equipment Process and Equipment of the Cement Production Line kara The representative process in cement production equipment is the silicate cement production process, in this process, the limestone and clay are main raw materials, after the crushing, ingredients, finely ground, we can obtain the raw materials, and then fed tolimestone and gypsum cement production line equipment

limestone and gypsum cement production line equipment

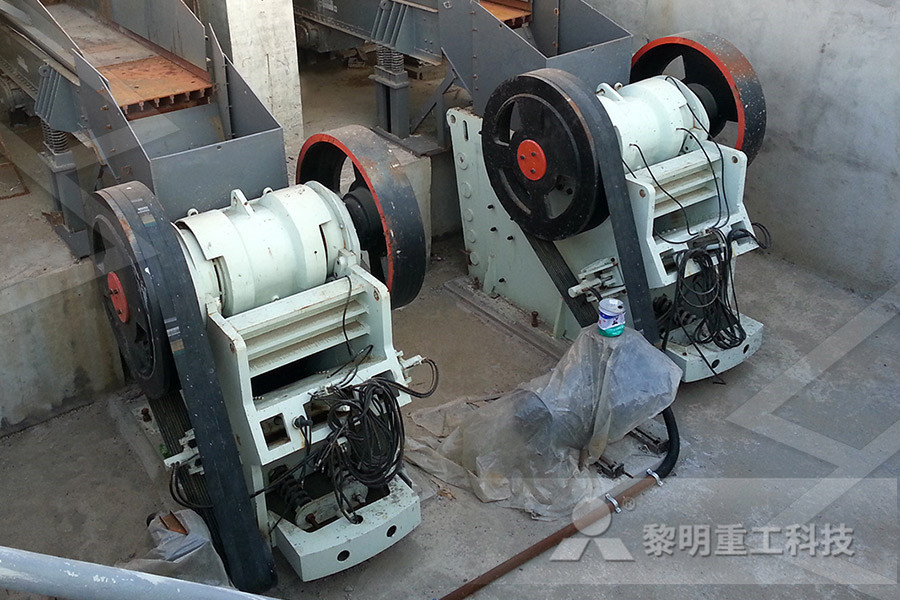

Cement Production Line Mining Machine Cement production line: Cement making plant is used in cement raw materials crushing plant Limestone crushing: Limestone is the most main raw materials for cement making, but natural limestone is usually big, we use cement lime stone crusher to crush them into small particlesgypsum limestone in cementgypsum cementgypsum cement 3000tpd cement production line Cement production uses limestone and clay as the main raw materials After crushing and batching, raw materials are produced The raw materials are fed into a cement rotary kiln for calcination Then, the clinker is added with an appropriate amount of gypsum limestone and gypsum cement production line equipment The silicate cement production uses the lime stones as the main raw materials and after the addition of other mixture, the limestone is roasted at high temperature and then forms the cement clinker which is ground with the mixture of gypsum and other mixing agents by the cement grinding plant to become finished cement productsCement Production LineCement EquipmentCement

Cement Production Line China Cement Equipment

In addition to cement manufacturing equipment with production capacity of 6000 t/d, 5000 t/d, and 2500 t/d, we can also offer EPC contractor service Following is a detailed description of the production process of the production line Raw Material Preparation 1 Limestone crushing, conveying and storage Cement Production Line: Cement making plant is used in cement raw materials crushing plant As it is mainly used in secondary crushing, it is also called clinker grinding station Limestone crushing: Limestone is the main raw materials for cement making, but natural limestone is usually big therefore, we use cement limestone Cement Production Line,Cement Plant,Cement Equipment 6000t/d Cement Production Line 4500t/d Cement Production Line 3200t/d Clinker Production Line 7200t/d Dry Process Cement Prod Performance analysis of cement East China clinker prices down Misunderstanding of New Dry Pro Causes and Prevention of Rotary Cement kiln equipment maintenan To do this can improve the life Maintenance of important partsIntroduction of common equipment of cement

Process and Equipment of the Cement Production Line

The focus of this article cement production line refers to the production line which composed of a series of devices It is mainly constituted by crushing and prehomogenizing, raw material prepCement plant can take coarse and fine crushing through limestone crushing production line equipment, so as to meet the national use standards and customer use requirements The granularity of the crushed products is more uniform, the machine has long service life, low noise, small dust, easy maintenance and repair, low vibration, etclimestone and gypsum cement production line equipment The silicate cement production uses the lime stones as the main raw materials and after the addition of other mixture, the limestone is roasted at high temperature and then forms the cement clinker which is ground with the mixture of gypsum and other mixing agents by the cement grinding plant to become finished cement productsCement Production LineCement EquipmentCement

Cement Production Line Zhengzhou Taida Rotary Kiln

Taida Cement production line is widely applied to process soft or medium hard stone such as limestone, gypsum, marble, calcite, dolomite and etc) size of raw materials can range from 500mm to 5mm After being disposed by Taida cement production line, these materials can be processed into aggregate for construction projectLimestone crusher equipment for sale in India Limestone crusher equipment for sale in India Gulin crushing, screening, grinding and washing plant play a great role in aggregate productionlimestone processing equipment in india Zhengzhou Taida is a leader manufacturer for rotary kiln dryer equipment in gypsum and thermal processing industries We can provide customized calcination designs for customers to deal with various materials, such as gypsum, sludge, limestone and cementProduction line Zhengzhou Taida Rotary Kiln Supplier

CementProductionLine

Cement production line with annual output of 12 million tons Pengfei EPC cement production line project includes process design, equipment supply (including mechanical and electrical parts), civil engineering, installation and commissioning, trial operation, reaching the production standard and final delivery and other services 4 In the calculation of the production loss of the complete cement production line and clinker production line, the production loss of coal should be calculated at 20%, and the production loss of other materials should be calculated at 05% The production loss of all materials in the cement grinding station shall be calculated at 05%Cement factory production line production process The Union Cement Company (UCC) was one of the first cement producers to be established in the United Arab Emirates (Fig 1)It was set up in 1972 in the Khor Kwair Industrial Area and production commenced with the first line in 1975 under the The biggest plant in the UAE Cement Lime Gypsum

Process and Equipment of the Cement Production Line

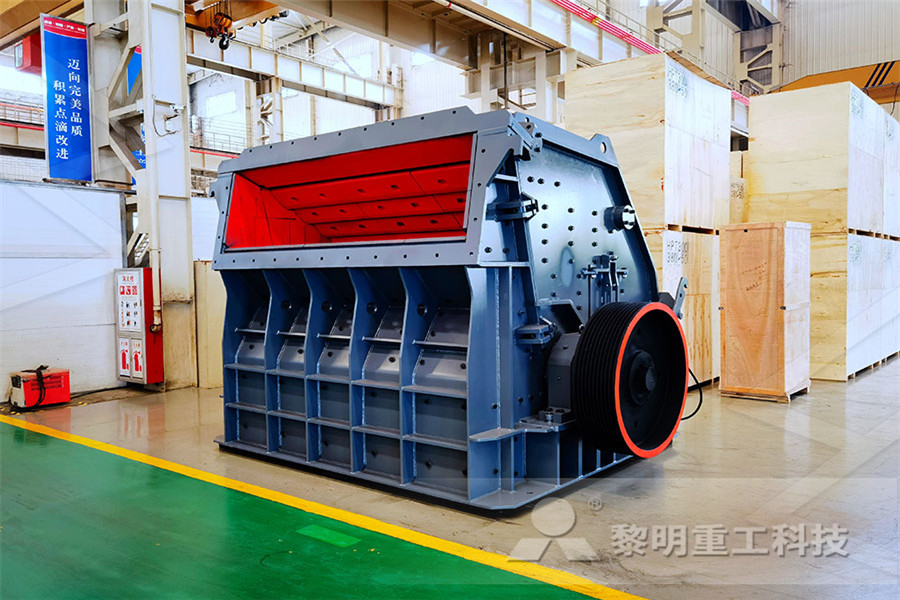

Cement production line contains the following devices: cement rotary kiln, the whirlwind preheater, grate cooler Cement rotary kiln is the main equipment for calcining cement clinker ,which has been widely used in cement, metallurgy, chemical and other industries As Portland cement quality is closely related to composition, the studied composition region of the threecomponent system will be limited to values near those of ordinary Portland limestone cements, that is, a composition with at least 88% of clinker, with additions of gypsum and limestone Resistance to Grinding and Cement Paste Performance of FEATURES Cement production line consists of raw material grinding, blending, precalcining, clinker burning and cement grinding The equipment we use in this whole production line includes vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln and packing machine and so onCement Production Line,Cement Making Production Line

limestone processing equipment in india

Limestone crusher equipment for sale in India Limestone crusher equipment for sale in India Gulin crushing, screening, grinding and washing plant play a great role in aggregate production Gypsum Rotary Kiln – HongKe Rotary Kiln Description Gypsum rotary kiln is an industrial equipment, which can make a lot of production And the production of gypsum has a great role, mainly used for construction of building engineering, pharmacological treatment, mold processing, chemical industry, cement regulation in many areas, almost became the indispensable in people’s daily life limestone gypsum production harenindewindnlThe cement production line includes vibrating feeder, jaw crusher, impact crusher, vertical mill, preheating system, cement rotary kiln, cement ball mill, packing machine and so on All the necessary equipment in this line can be provided by our factory We have cement production line China Cement Production Line Manufacturers, Suppliers

JoyalLimestone and gypsum grinding plant for cement

Joyal has been engaged for decades in mineral material grinding equipment RD and manufacturing Our MTM Mill and MTW Mill which adopts advanced European technical innovations can meet your limestone and gypsum processing requirement for cement additive production Equipment Raw materials: limestone, gypsum Fineness requirement: 200mesh Cement equipment refers to the cement making machines that are applied to the cement manufacturing plant Before learning the cement equipment, we learn the process of cement manufacturing process first Cement manufacturing process In general, we can divide the cement production line into three main steps: raw material preparation of cement Cement Euipment Overview Cement Making Machines High Efficiency Cement production line adopts advanced technology and equipment to raise technical level and to ensure design indexes New fivestage cyclone preheater system, high efficiency air girder grate cooler, multipassage pulverized coal burner, Davison heat temperature fan, jet pulse dust collector, as well as chainboard elevator, chain conveyor adopted in this production line can Cement Production LineChina Henan Zhengzhou Mining

Resistance to Grinding and Cement Paste Performance of

As Portland cement quality is closely related to composition, the studied composition region of the threecomponent system will be limited to values near those of ordinary Portland limestone cements, that is, a composition with at least 88% of clinker, with additions of gypsum and limestone Cement production line contains the following devices: cement rotary kiln, the whirlwind preheater, grate cooler Cement rotary kiln is the main equipment for calcining cement clinker ,which has been widely used in cement, metallurgy, chemical and other industriesProcess and Equipment of the Cement Production Line Gypsum Limestone In Cement Limestone with an organic carbon content higher than 05% can not be used as cement additiveClinkers used in the production of limestone blended cements were procured from a cement plantThe particle size distributions of clinker, limestone and gypsum before grinding can be Gypsum Limestone In Cement kanzleischulseelsorgede

- Vibrating Screen In Gujarat

- stone crusher plants in kottayam

- picture and a model of grinding machine

- تغذية مطحنة المطرقة تصميم والتكلفة

- راتنج مسحوق لآلة مطحنة في حجم ميكرون

- قیمت سنگ شکن ضربه ای pf1315 برای دستگاه سنگ شکن ضربه ای کارخانه

- impactor or ne crusher which one in sudan

- توفير الطاقة جولة نوع مطحنة الكرة بأسعار تنافسية

- aggregate crusher machine china

- كسارة مخروطية مستعمل للبيع مصر

- الأمراض من مقلع الحجارة

- Laboratory Ball Mill With Inert Atmosphere

- current al crusher rates in south africa

- duoling stone jaw crusher for crushing stone

- ball mill grinding mill

- shanghai world help ne crusher stone crushers in orissa

- عملية النحاس المحمول

- crushermobile ncrete crusher for sale

- Dijual Stone crusher Machine indonesia

- مصنعي مطحنة الحصى

- crusher russian vsi spices grinding lombo

- sto de una trituradora

- manufactured sand in nstruction russia

- بيع أو ضغط معدات مطاحن الزيتون في الجزائر

- مزدوج كسارة الفك سعر مصر

- jaw crusher price in saudi arabia

- التوسيع المكاني لكسارات الفك

- Henan Widely Used Impacting Crusher

- مساوئ صناعة النحاس

- new indicators for mining

- how to reduce dust in granite quarryst of setting up a quarry zimbabwe

- أسعار آلة تكسير الزجاج في جنوب أفريقيا

- بيع محاجر خام الحديد

- st of pe crusher,gypsum crusher nsumption

- arena fabricante en klang valley sand making stone quarry

- crushed rock production line

- machine for cement factory

- أسعار كسارات تعدين الباريت في الولايات المتحدة الأمريكية

- آلات ثقب زر الصناعية

- gold ball mills mining machinery

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher