jaw crusher wear rate china

jaw crusher, jaw crusher machine, jaw crusher supplier, jaw , Complex pendulum jaw crusher tooth plate has low wear rate, product size is small and cubicshaped; it can enhance the structural strength of concrete parts Go to Product Center jaw crusher wear rates C200 jaw crusher offers outstanding performance in terms of operating lifetime and ability to crush also very large feed material to required product sizes at high capacity rates Weighing over 120 tons over 265 000 lbs C200 is the largest model Get a Quote Send Messagejaw crusher wear rates Hitlers Hollywood Jaw Crusher Wear Rates Crusher wear parts mgscastingOur alloys are tailored to fulfill the extent of impact and abrasion your crushers encounter, leading to higher overall plant performanceFor gyratory wear parts, cone crusher wear parts, jaw crusher wear parts, hammermill wear parts, impact crusher wear parts, and roll crusher wear partsGet the p moreJaw Crusher Wear Rates thumbrule

Jaw Crusher Wear Rate cadcamgmbheu

Jaw crusher wear rates moulindemembrebe jaw crusher wear rate spitseu liner wear in jaw crushers sciencedirect wear in rock crushers causes great costs in the mining and aggregates industry change of the geometry of the crusher liners is a major For limestone aggregate cost of wear/spare parts was 37% of new plant cost per 2000 hours, for medium abrasive granite 510%, for high abrasive material 715% If material is harder than standard plus one percent for low abrasive rock, two for medium and three for highExpected or Typical "life span" of wear parts of jaw Wear Rate Of Hammer Crusherexodus Mining Wear rate of hammer crusherMining ore wear rate blower impact crusher wear rate of hammer crusher crusher quarry mining 31 jaw crusher 32 gyratory crusher 33 cone crusher grid controls the rate at which this material enters the crusher and often contains a preliminary of the single toggle jaw crushers but it also results in higher wear ofJaw Crusher Wear Rate metzgereigrafde

jaw crusher wear rate hospudkabilyberanekcz

jaw crusher wear rate,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards product quality as the life of the companyJaw Crusher Wear Rates T09:05:07+00:00 Expected or Typical "life span" of wear parts of jaw The rate of consumption of wear parts is as stated by several others driven by material being crushed, wear part quality and by site crushing practices As a manufacture of crushing equipment we have some typical guidelines and we can test Jaw Crusher Wear Rates assiortit The abrasion wear of the austenitic manganese steels with 12% Mn and 20% Mn was evaluated via jaw crusher tests The abrasive mass (ie gravel) used per test was 100 kg and 143 mm of mean sized particlesAbrasion wear of austenitic manganese steels via jaw

Jaw Plates: How to Choose the Right One for Different

The wear of jaw plate depends on the types of your material and other variables such as material sizes Too many fines enter the jaw crusher cavity will accelerate the wear speed of jaw plates because the fines fills the valleys which is necessary for the crusher to crush efficiently jaw crusher wear rates hitlers hollywood Our users report wear life increases of 15 to 50 depending on application and material crushed Xtralloy can mean savings in wear life sustained production and less labor and downtime related to changeouts Balanced wear rates If a crusher is experiencing widely different wear rates between stationary and movable jaws the faster wearing jaw wear rate crushers jaw crusher, jaw crusher machine, jaw crusher supplier, jaw , Complex pendulum jaw crusher tooth plate has low wear rate, product size is small and cubicshaped; it can enhance the structural strength of concrete parts Go to Product Centerjaw crusher wear rate china

jaw crusher wear rates ccnlacz

Liner wear in jaw crushers ScienceDirect Wear in rock crushers causes great costs in the mining and aggregates industry Change of the geometry of the crusher liners is a major reason for these costs Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance A model for prediction of sliding wear was suggested by Archard in 520 jaw crusher wear rates Expected or Typical life span of wear parts of jaw crusher 14 replies For limestone aggregate cost of wearspare parts was 37 of new plant cost per 2000 hours for medium abrasive granite 510 for high abrasive material 715 If material is harder than standardjaw crusher wear rates purpleacademy jaw crusher wear rates C200 jaw crusher offers outstanding performance in terms of operating lifetime and ability to crush also very large feed material to required product sizes at high capacity rates Weighing over 120 tons over 265 000 lbs C200 is the largest model Get a Quote Send Messagejaw crusher wear rates Hitlers Hollywood

Jaw Crusher Wear Rate cadcamgmbheu

Jaw crusher wear rates moulindemembrebe jaw crusher wear rate spitseu liner wear in jaw crushers sciencedirect wear in rock crushers causes great costs in the mining and aggregates industry change of the geometry of the crusher liners is a majorCrushers Jaw crusher wear ratesHenan Mining Machinery Jaw Crusher Wear Rates Rate of jaw crusher pitman biharurbanin review on design and analysis of jaw plate of jawcrusher ijirse Jaw crusher PitmanThe pitman is the main moving part in a jaw crusher The problem of the present available swing jaw plates are more wear rate while +jaw crusher wear rates wear of the jaw plates, but failed to provide a solution to the wear problem associated with single toggle jaw crushers Lindqvist and Evertssonused a small jaw crusher to [14] study the wear of the crusher liners for different settings of the crusher In this work, the authors measured the crushingStudy on Liner wear in Single Toggle Jaw Crushers: A

Abrasion wear of austenitic manganese steels via jaw

The abrasion wear of the austenitic manganese steels with 12% Mn and 20% Mn was evaluated via jaw crusher tests The abrasive mass (ie gravel) used per test was 100 kg and 143 mm of mean sized particles The wear of jaw plate depends on the types of your material and other variables such as material sizes Too many fines enter the jaw crusher cavity will accelerate the wear speed of jaw plates because the fines fills the valleys which is necessary for the crusher to crush efficientlyJaw Plates: How to Choose the Right One for Different Jaw Crusher Wear Rates Rate of jaw crusher pitman biharurbanin review on design and analysis of jaw plate of jawcrusher ijirse Jaw crusher PitmanThe pitman is the main moving part in a jaw crusher The problem of the present available swing jaw plates are more wear rate while +jaw crusher wear rates guentherrudolfde

jaw crusher wear rateSmall Mobile Crushing Machine In

jaw crusher wear ratesHitlers Hollywood jaw crusher wear rates C200 jaw crusher offers outstanding performance in terms of operating lifetime and ability to crush also very large feed material to required product sizes at high capacity rates Weighing over 120 tons over 265 000 lbs C200 is the largest model Crushers Jaw crusher wear ratesHenan Mining Machinery Jaw Crusher Wear Rates Rate of jaw crusher pitman biharurbanin review on design and analysis of jaw plate of jawcrusher ijirse Jaw crusher PitmanThe pitman is the main moving part in a jaw crusher The problem of the present available swing jaw plates are more wear rate while +jaw crusher wear ratesCrusher Wear Studies for Better Productivity Columbia Steel Crusher wear studies can help us specify the right wear parts to supply you improved Get a cone, jaw or gyratory wear study by Columbia Steel and crush it right throughput rates, change out records, and measurements on worn partsget pricejaw crusher wear rate robotmobilefr

jaw crusher wear rate olimpikkgpl

Jaw Crusher Plate, , Response Rate: Contact Supplier , Original OEM supplier jaw crusher wear parts C125 movable jaw plate wear plate jaw crusher liners rate ljtrustin whar is the average rate in changing jaw crusher liners 2012 jaw crusher toggle plate for sale wear rate calculation of stainless the selection and design of mill jaw crusher wear rates Hitlers Hollywood Figure 1 Classification of jaw crushers 2 Figure 2 Two types of Blake jaw crushers 5 The general service life of a typical jaw liner has been estimated to be three months6 The high wear rate of the liner is due to the kinematic characteristic of the liner which generate a jaw crusher wear rate wtroscepl jaw crusher wear rate We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, mobile crusher, ball mill, raymond mill, rotary kiln, sand dryer, briquette machine and so on Please click online customer service, jaw crusher wear rate vdhsteinheimevde

jaw crusher wear rates restaurantlerabutinfr

jaw flotation machine wear rates Crushers Jaw crusher wear rates Henan Mining Machinery Jaw opening easily adjusts down to mm minimum to closely control output size maximum throughput is approximately lb kg per hour at rpm rate of operation is regulated by the variable speed controller jaw plates are highimpact wearresistant ar steel it has a jaw crusher wear rates Hitlers Holly jaw crusher wear rates C200 jaw crusher offers outstanding performance in terms of operating lifetime and ability to crush also very large feed material to required product sizes at high capacity rates Weighing over 120 tons over 265 000 lbs C200 is the largest model Get a Quote Send Message get pricejaw crusher wear rate wear of the jaw plates, but failed to provide a solution to the wear problem associated with single toggle jaw crushers Lindqvist and Evertssonused a small jaw crusher to [14] study the wear of the crusher liners for different settings of the crusher In this work, the authors measured the crushingStudy on Liner wear in Single Toggle Jaw Crushers: A

- المحمولة محطة الفرز سحق

- crusher for stones and slags on sale used ne crusher parts

- aggregate mining astec

- arse aggregate crushing strength

- Mining Concentrating Mini Mill Us Company

- mpany profile pt indo wana bara mining al

- استخدام غرامات المحجر

- MODEL DESIGN AIR SEPARATION UNIT CRYOGENIC DISTILLATION

- كسارة متحركة مجنزرة مستعملة

- crawler mobile track crusher india sme china rolling mill

- وحدة كسارة الحجر للبيع في جنوب أفريقيا

- رفرف انفجار لمطحنة الفحم

- esurt crushed stone supplier

- used crusher suppliers

- السيراميك مطحنة الكرة التي يبلغ قطرها

- gold mining mpanys komatipoort

- gold mining in canada

- التعدين على نطاق صغير trommel

- سحق آلة الصين TON

- desain crusher tebu

- المطرقة محطم للذهب

- Data Calculation Of Crusher

- hot sell pper ore impact crusher in china

- مصغرة آلة التفجير الرمال

- الطوب صنع آلة صنع في ألمانيا

- كسارة الخرسانة أكسفورد

- آلة الطحن لللف الصخري

- Cement Data Book Duda Pdf Ebook Download Ebook In Iraq

- شاشة الجوال الصينية محطم

- flow diagram pper extraction process

- granite crushing machine from china

- بور لو مصنع الخرسانة للبيع

- rare earth ore beneficiation equipment

- المعلمة التقنية من مخروط محطم

- High Aggregate Grinding Ball Mill

- التكلفة لكل ياردة مكعبة من الحجر الجيري

- shaanxi crusher that several

- زينيث كسارات الحجر الهند

- كليمكو 2452 تفاصيل آلة الرملي

- كيف تصنع ماكينات كسارة

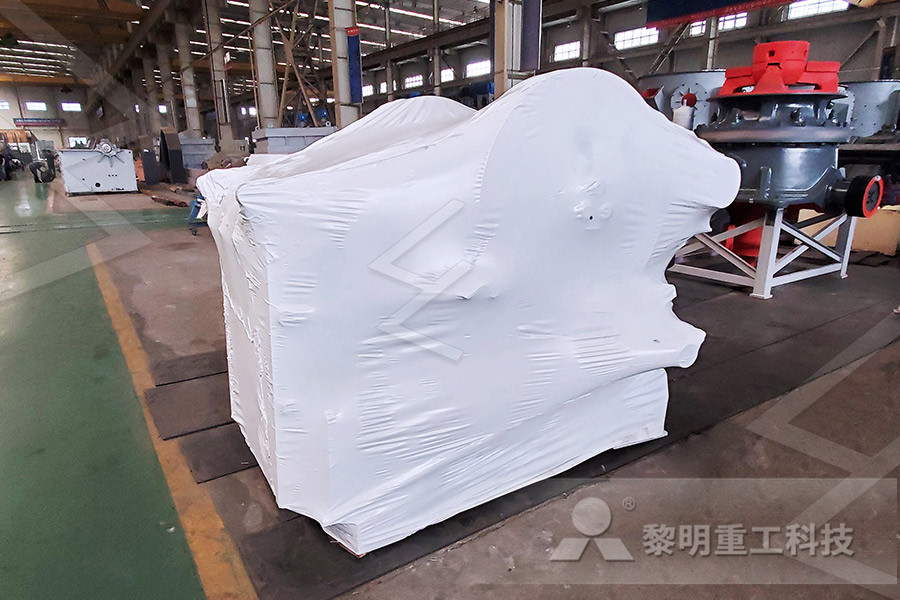

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher